Heat exchanger comprising bypass channels

A heat exchanger, bypass channel technology, applied in heat exchange equipment, heat exchangers, heat exchanger shells, etc., can solve problems such as large flow loss of exhaust gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

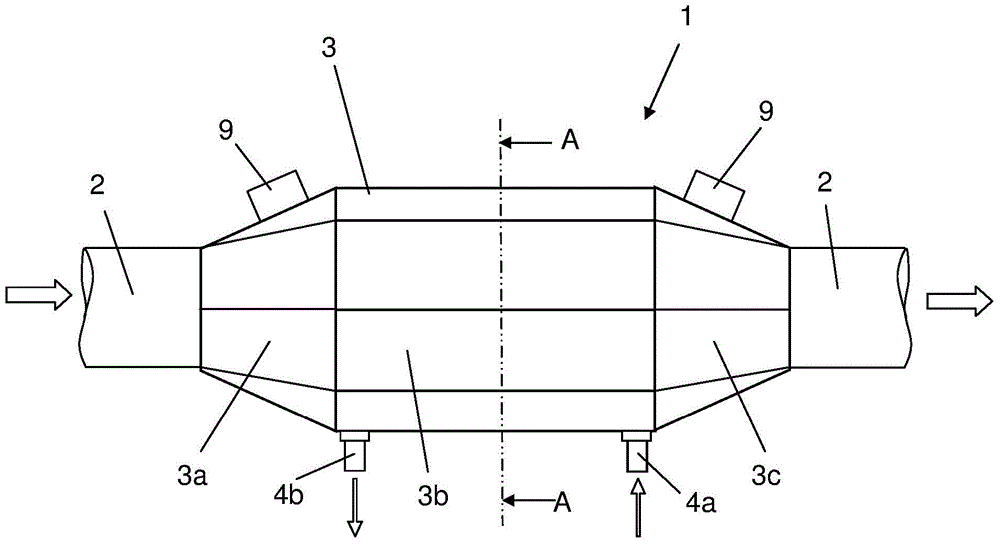

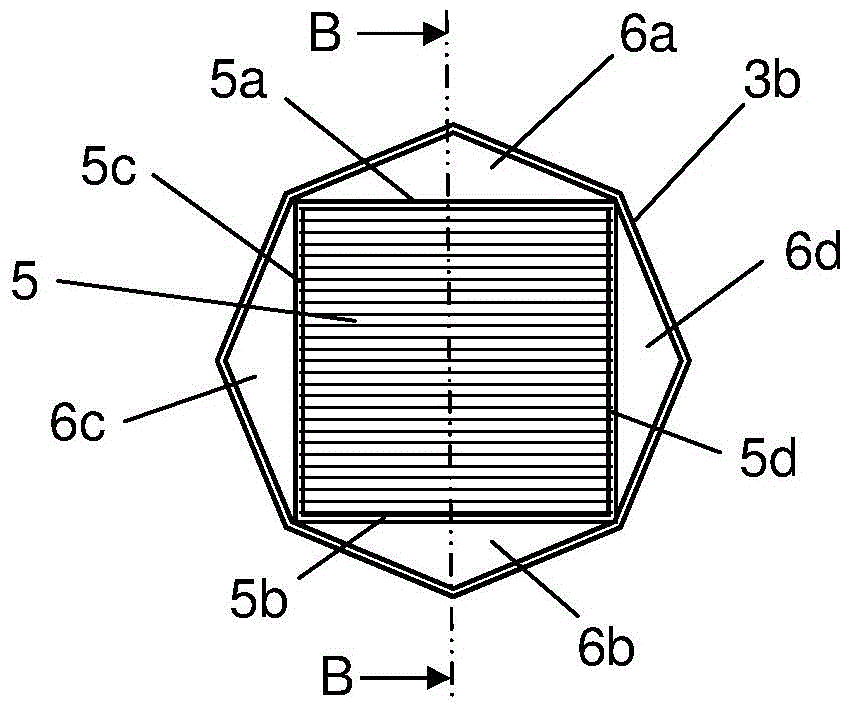

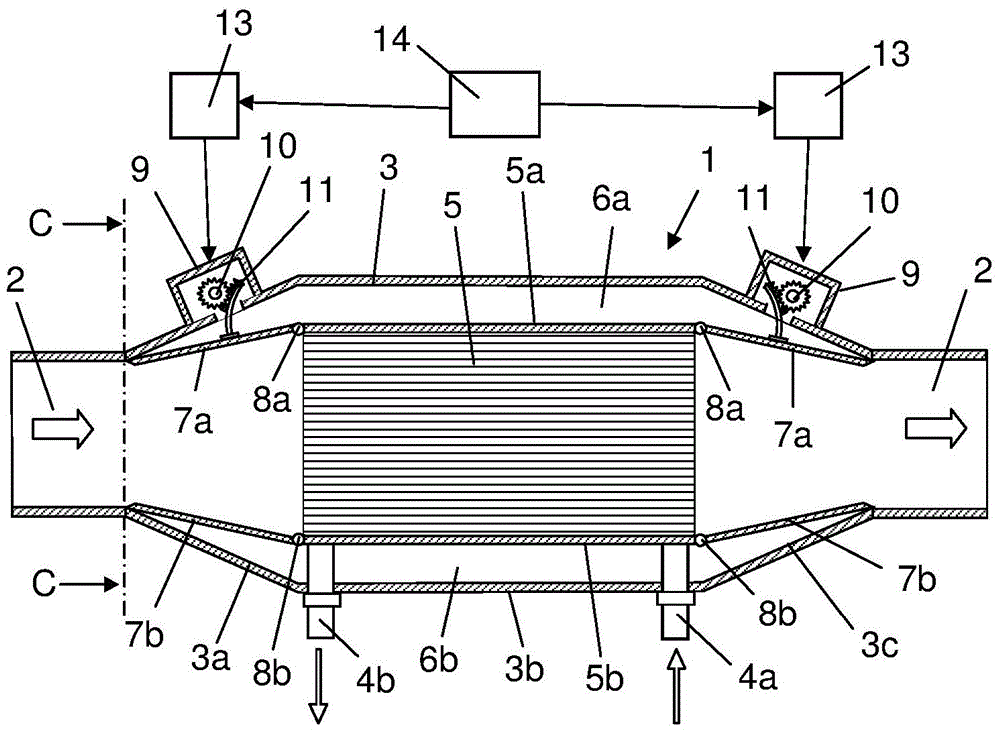

[0021] figure 1 A heat exchanger is shown. The heat exchanger is exemplified here as an intercooler 1 in a vehicle operated by a heavy-duty combustion engine. The first medium in the form of charge air is cooled in the intercooler 1 . The intercooler 1 is arranged inside an air line 2 which conducts charge air to the combustion engine. The intercooler 1 comprises a container 3 which forms the outer surface for the intercooler 1 . The container 3 is composed of an inlet section 3a, a middle section 3b and an outlet section 3c. The inlet section 3a has a continuously increasing cross-sectional area in the longitudinal direction starting from the connection to the part of the air line 2 arranged upstream of the intermediate section 3b. The middle section has a constant cross-sectional area. The outlet section 3 c has a continuously decreasing cross-sectional area in the longitudinal direction from the middle section 3 b to the connection to the part of the air line 2 positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com