Shotgun shell dispenser

a dispenser and shotgun shell technology, applied in the field of cartridge carriers, to achieve the effect of convenient dispense and refilling of cartridge carriers, and easy stacking together

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

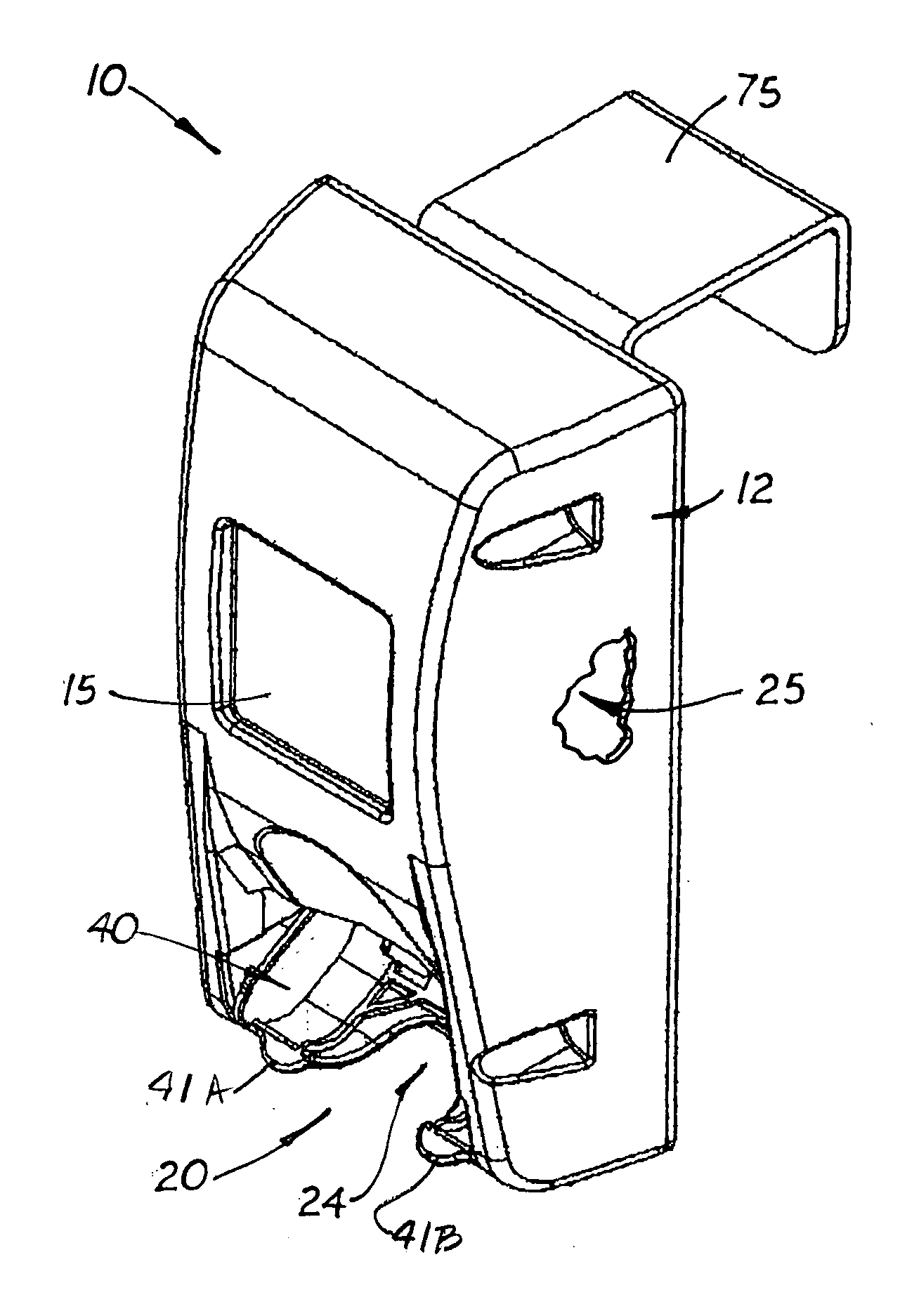

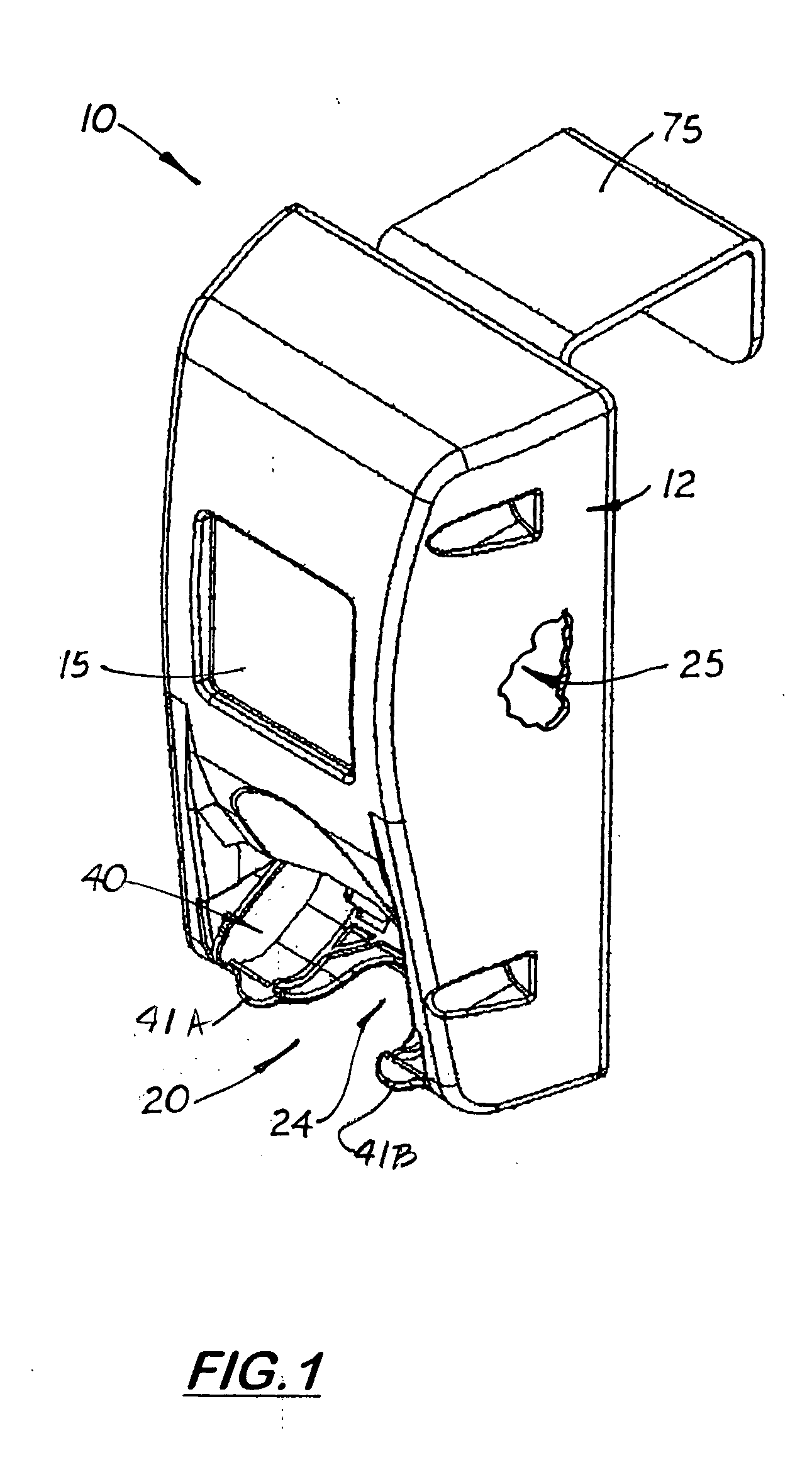

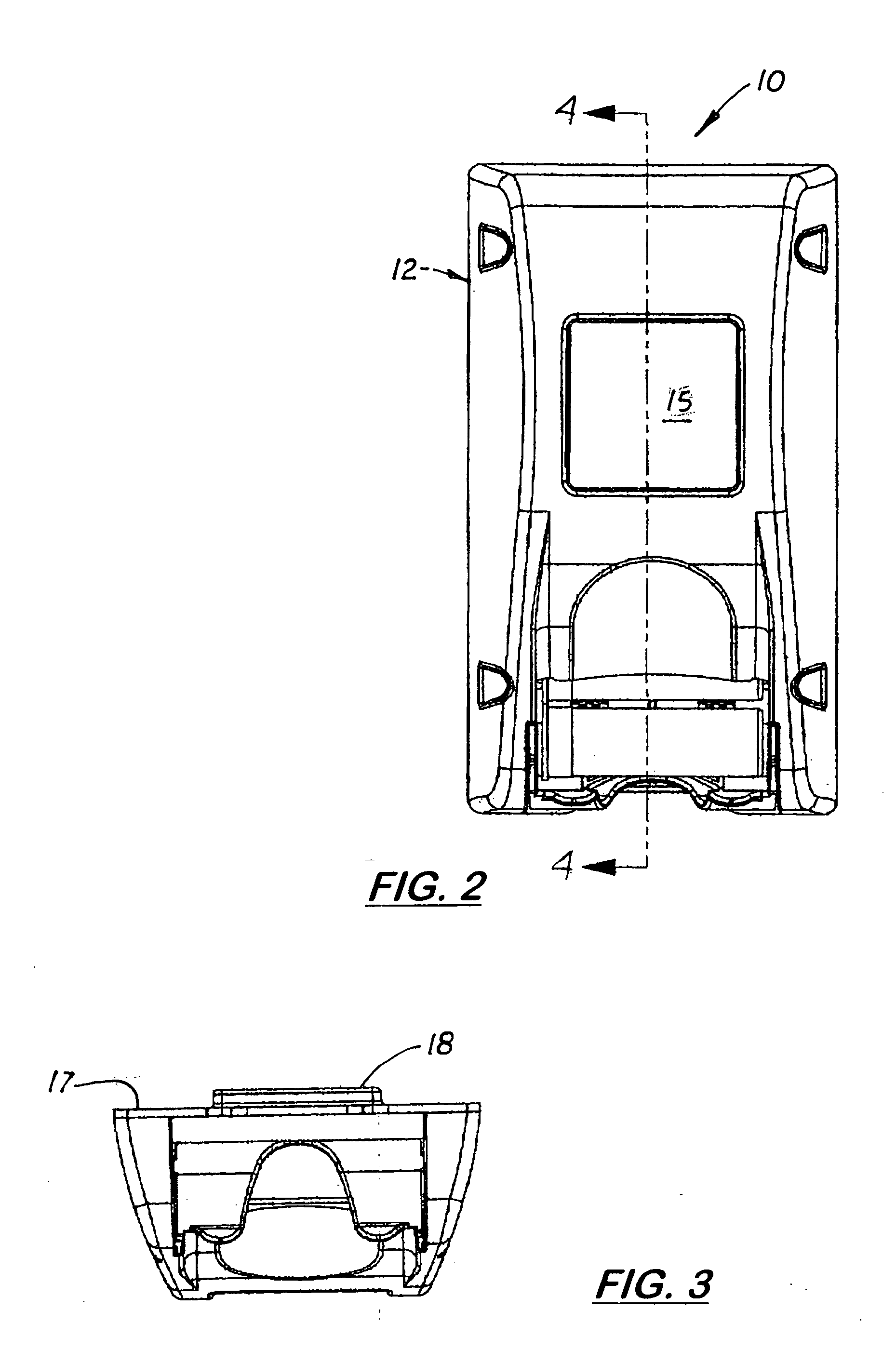

[0026] Referring the Figs., there is shown a shotgun shell dispenser 10 used to carrier a plurality of shot gun shells 90 specially designed to allow a hunter to easily remove and load individual shells 90 into the dispenser 10 using the fingers on one hand. The dispenser 10 is also specifically designed to allow the hunter to pre-pack multiple dispensers 10 and then stack them in an organized manner inside a box or suitable container.

[0027] The dispenser 10 includes a rectangular-shaped, six-sided housing 12 with a lower loading and discharge opening 20. Located on the lower end wall of the housing 12 adjacent to the lower loading and discharge opening 20 is a pivoting ball 40 with a u-shaped finger cutout 24 formed thereon that allows the hunter to extend his or her middle finger around a shell 90 disposed on the bail 40. The housing 12 includes a hollow cavity 25 designed to hold a row of stacked, transversely aligned shells 90. (See FIG. 5)

[0028] Located inside the hollow cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com