Display containers with removable panel

a technology of display containers and lid panels, which is applied in the field of paperboard, corrugated craft and similar containers, can solve the problems of compromising the structural integrity of the container, the insufficient size of the container, and the rough handling of containers, so as to prevent the interference of the panel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

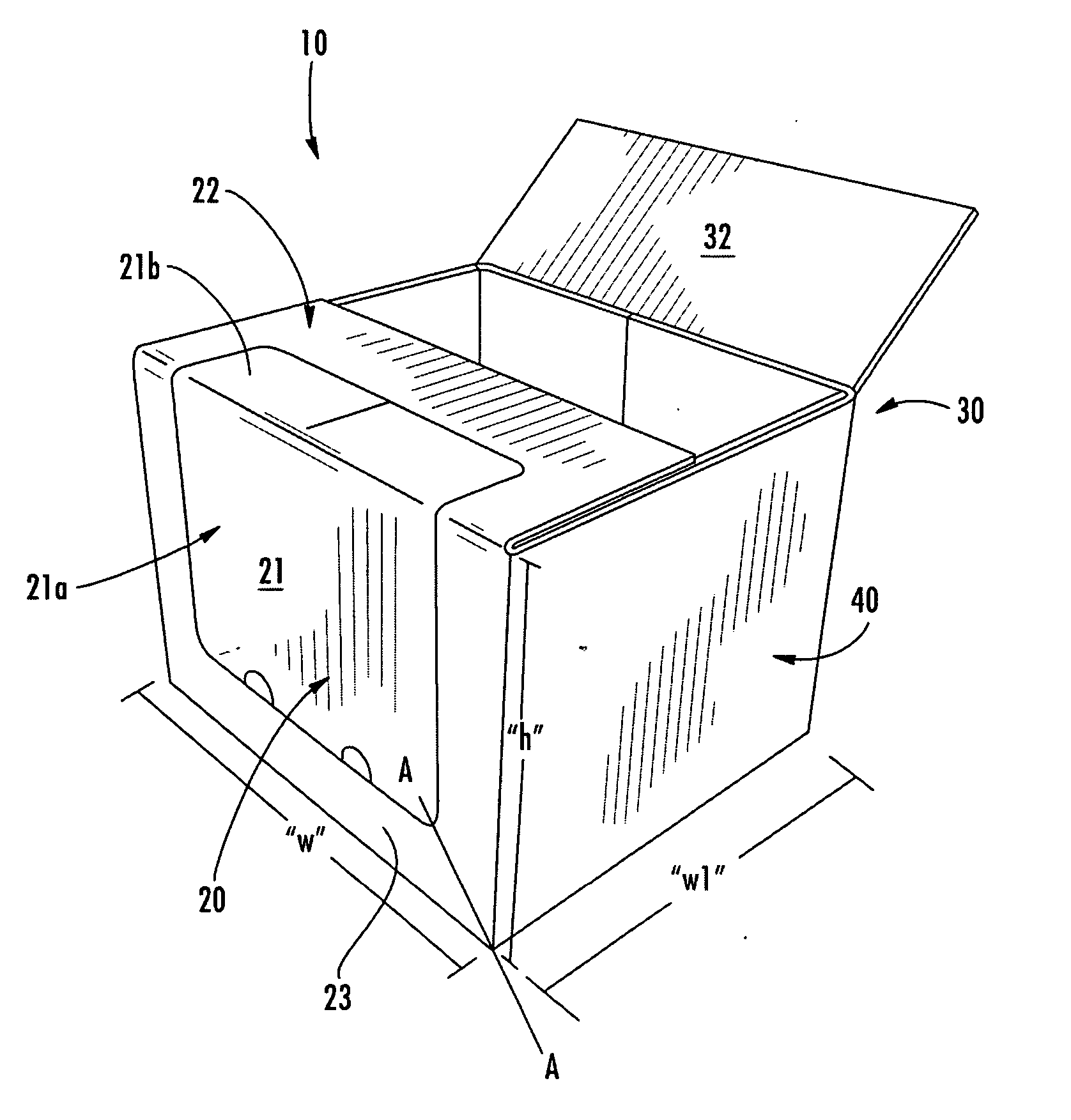

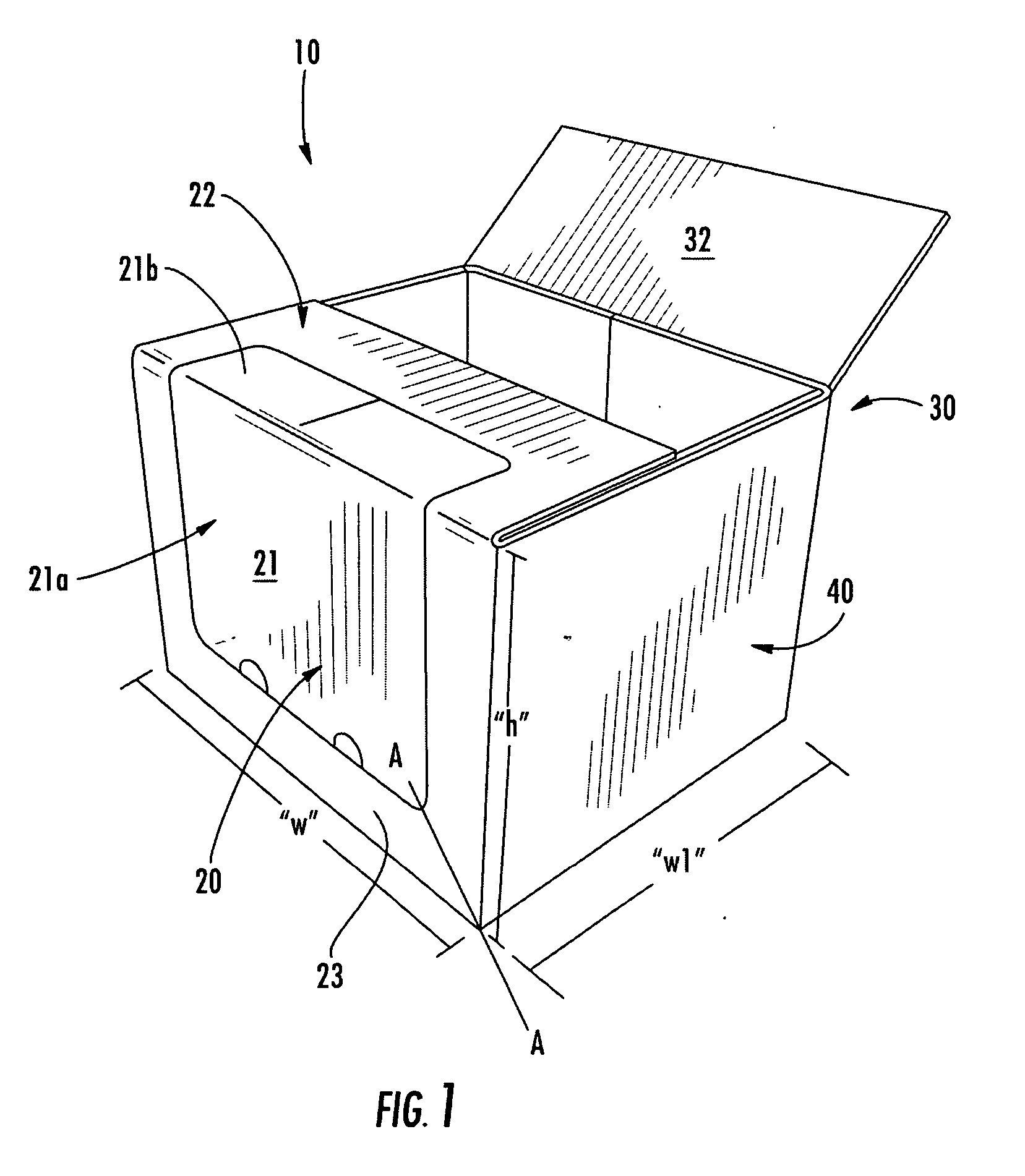

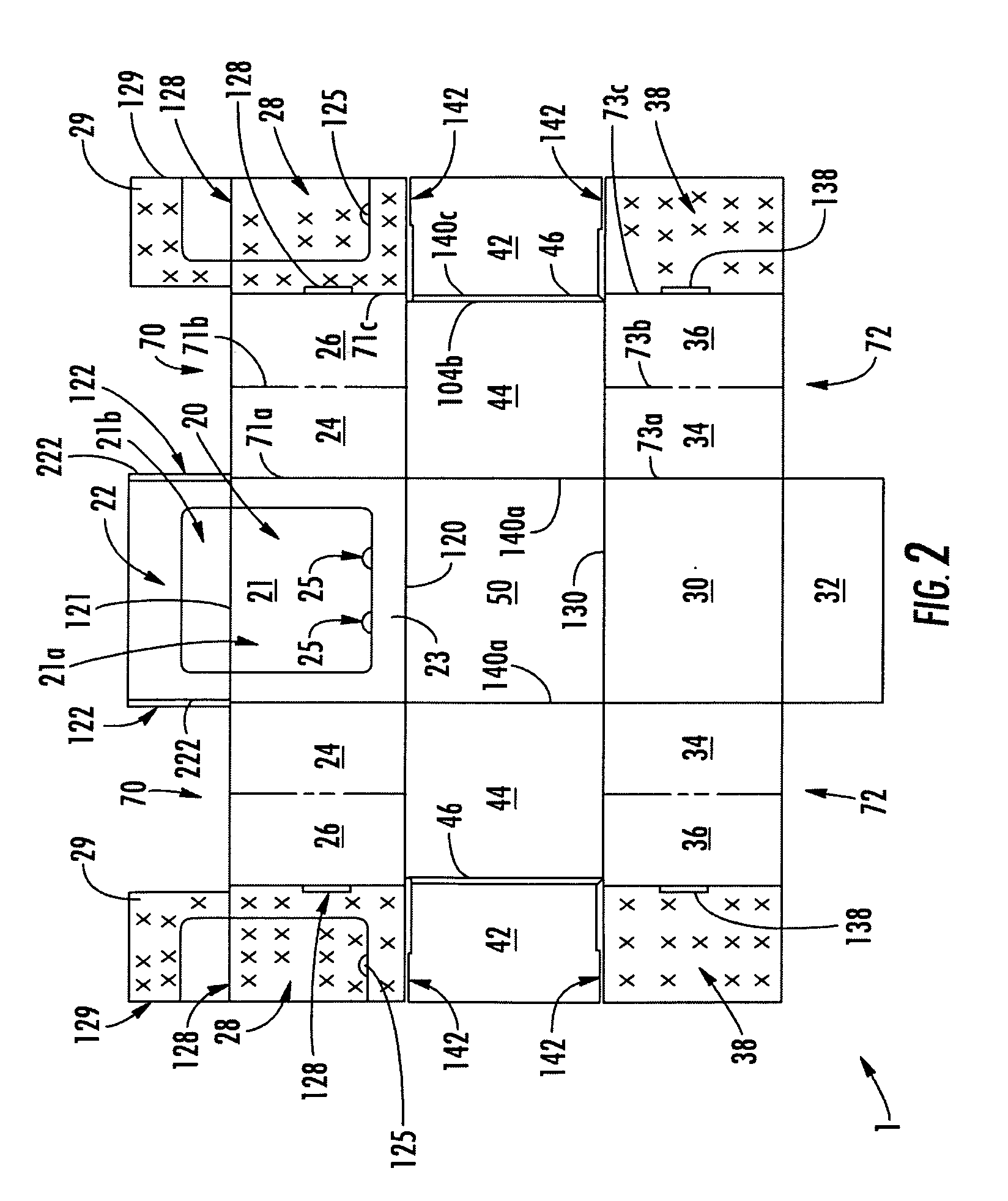

[0035] Referring to FIGS. 1 and 2, a reinforced container 10 has a front wall 20 a back wall 30, and end walls 40 projecting upwardly from a one-piece bottom 50. Front and back walls 20, 30 and end walls 40 are integral with container bottom 50 and are joined to bottom 50 by respective longitudinally extending folds 120, 130 and transversely extending folds 140, respectively. The front and back walls 20, 30 have in-fold flaps 22, 32, for forming a top of the container when folded over parallel to the bottom 50. A tear-out panel 21 is formed in a portion of the front wall 20 and extends onto its associated in-fold flap 22 to allow for easy access to the contents of the container 10 and to provide an attractive display appearance.

[0036] In the embodiment of FIG. 3, the bottom is comprised of a plurality of in-fold flaps 1050a-d instead of a one-piece continuous bottom panel as in FIGS. 1 and 2. Advantageously, all the panels forming container 10 are integral portions of a single flat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com