Elastomeric multicomponent fibers, nonwoven webs and nonwoven fabrics

a multi-component fiber and nonwoven fabric technology, applied in the field of nonwoven fabrics, can solve the problems of requiring a significant amount of space within the manufacturing facility, drawing rolls can impart non-uniform stretching, and tenter frames are expensiv

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

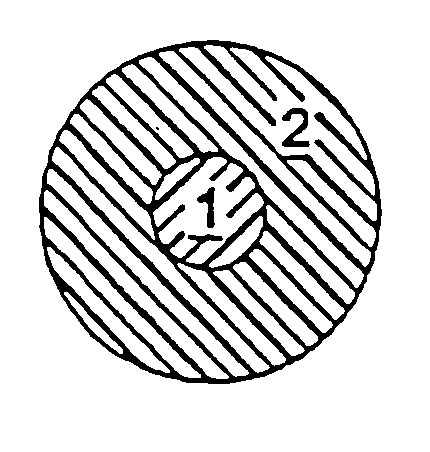

[0109] A web of 10 / 90 sheath / core bicomponent filaments was prepared on a spunbond apparatus similar to that described in FIG. 4. The core was prepared from PELLETHANE2103-70A polyurethane and the sheath was prepared from Dow ASPUN 6811A polyethylene. The filaments were spun through a die having 144 holes of 0.35 mm diameter. The filaments were drawn at a speed of approximately 600 m / min through an air attenuation device and distributed on a foraminous belt as a web of 68 gsm basis weight. The denier of the filaments was approximately 5. The web was thermally point bonded at a temperature of 111° C. and passed through mechanical incremental stretching devices so that it was stretched in both the machine direction and the cross machine direction. The mechanical properties of the fabric are given in Table 1.

example 2

[0110] A web of 9 / 91 sheath / core bicomponent filaments was prepared in the apparatus used for Example 1. The core was prepared from PELLETHANE2102-75A polyurethane and the sheath was prepared from Arco 40-7956X polypropylene. The web was thermal point bonded at 136° C. and mechanically incrementally stretched in both the machine direction and the cross machine direction. The mechanical properties of this fabric are given in Table 1.

example 3

[0111] A web of 10 / 90 sheath / core bicomponent filaments was prepared on an apparatus similar to that described in FIG. 4. The core was prepared from PELLETHANE2102-75A polyurethane and the sheath was prepared from Arco 40-7956X polypropylene. The filaments were spun through a die having 4000 holes of 0.35 mm diameter across a width of 1.2 meters. The filaments were drawn at a speed of approximately 1200 m / min through an air attenuation device and distributed on a foraminous belt to form a web of 50 gsm basis weight. The denier of the filaments was approximately 5. The web was thermal point bonded at a temperature of 138° C. and mechanically incrementally stretched in both the machine and cross machine direction. The mechanical properties of this fabric are given in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com