Customizable row assembly and method of manufacturing a window covering

a technology of custom assembly and window covering, which is applied in the direction of wing arrangement, door/window protective device, shutter/movable grille, etc., can solve the problem that the custom process requires a substantial amount of time to custom build, and achieve the effect of shortening the overall width, facilitating the shortening of the anchor member, and adjusting the overall width of the elongated member

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The invention disclosed herein is susceptible of embodiment in many different forms. Shown in the drawings and described hereinbelow in detail are preferred embodiments of the invention. It is to be understood, however, that the present disclosure is an exemplification of the principles of the invention and does not limit the invention to the illustrated embodiments.

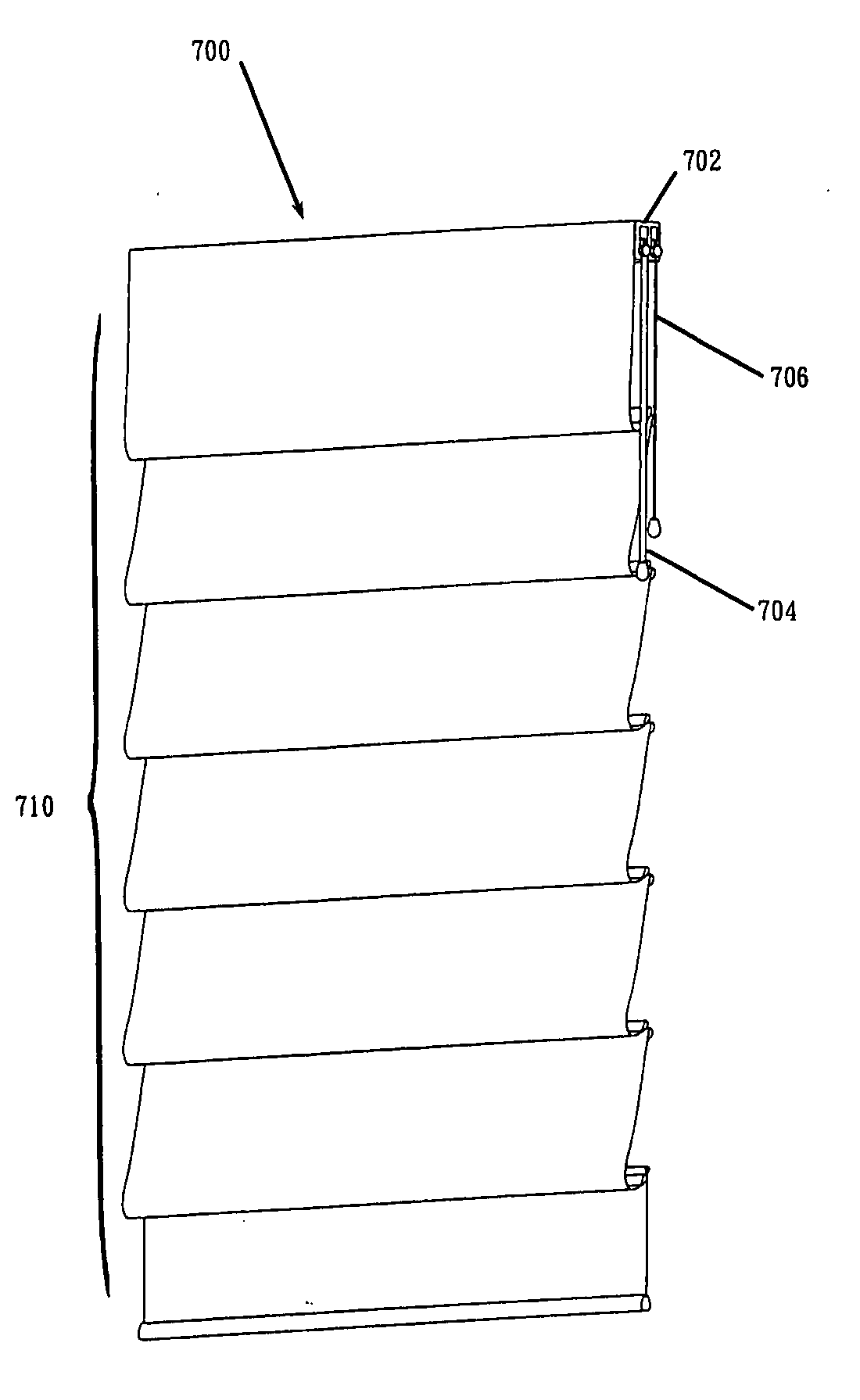

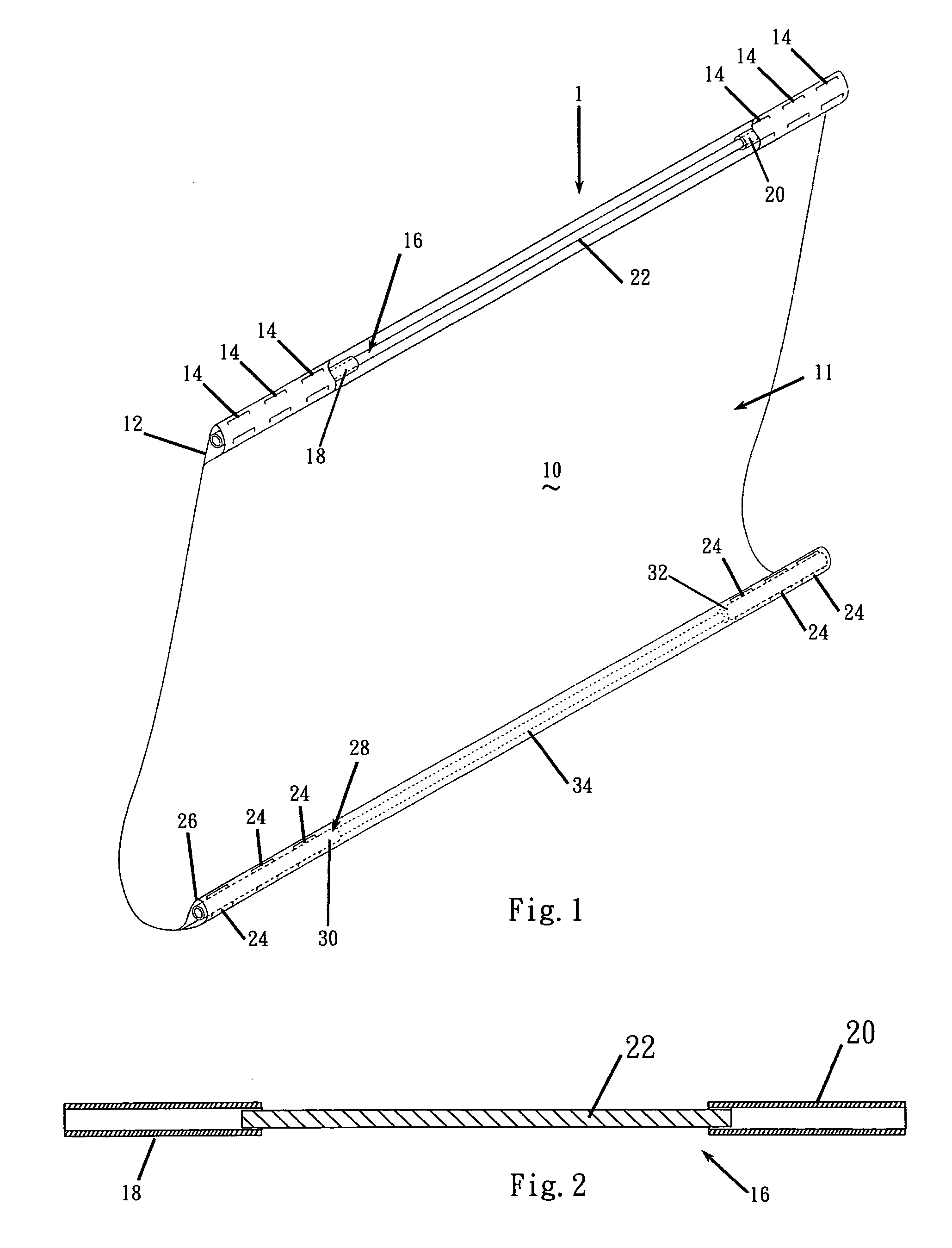

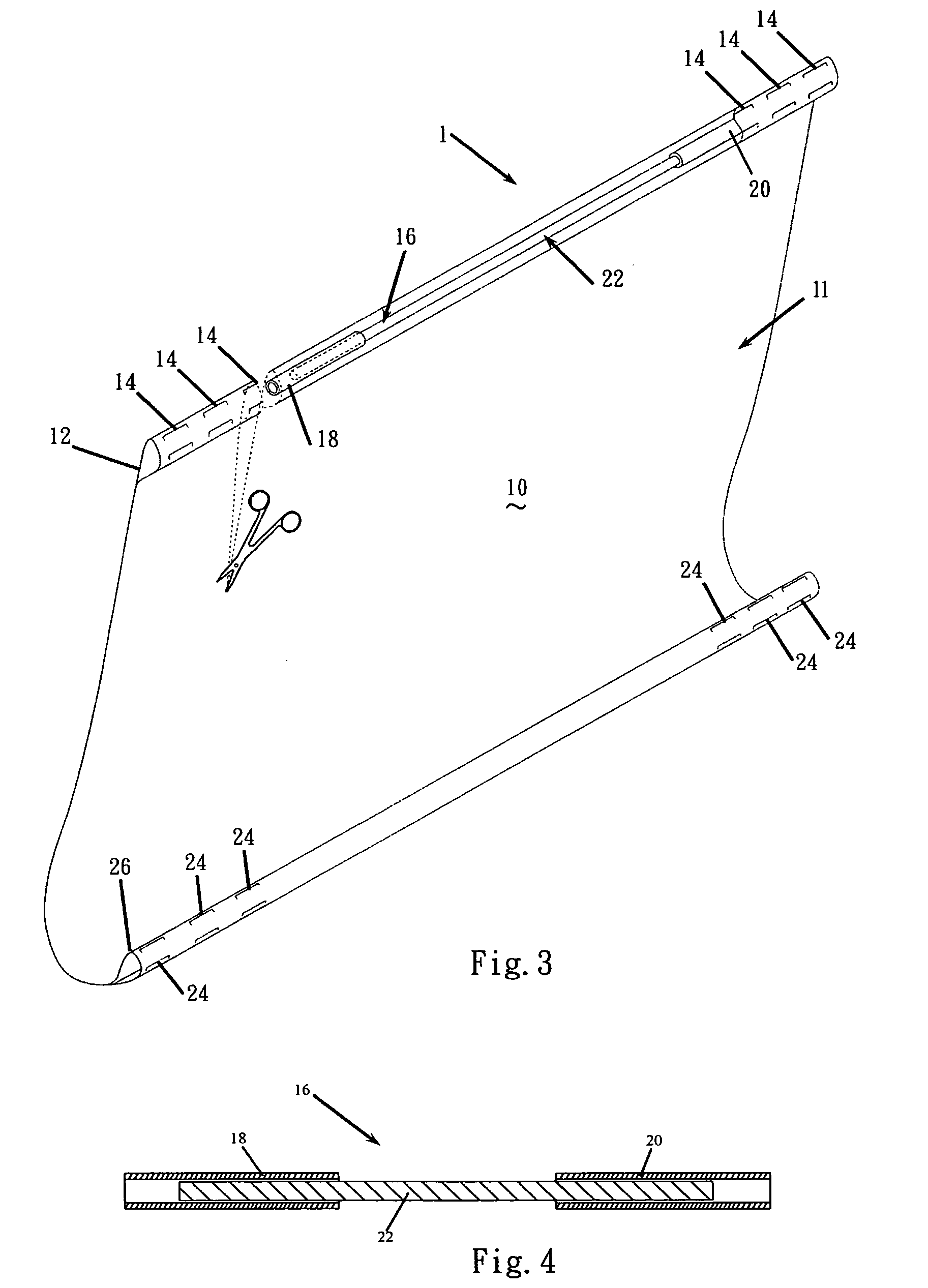

[0036] As shown in FIG. 1, a row 1 is shown. The row 1 includes a panel 10 that includes a main or central portion 11 and a longitudinal portion 12. The longitudinal portion 12 forms a loop and defines a plurality of spaced openings 14. The loop may be formed by overlapping a portion of the panel 10 over itself and securing an edge to the main portion 11 of the panel 10 through any means known in the art such as gluing, welding, sewing or the like. Inserted within longitudinal loop portion 12 is anchor member 16. In this embodiment, anchor member 16 is formed of a pair of sleeve or tube members 18 and 20, and a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com