Shipping and display tray

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

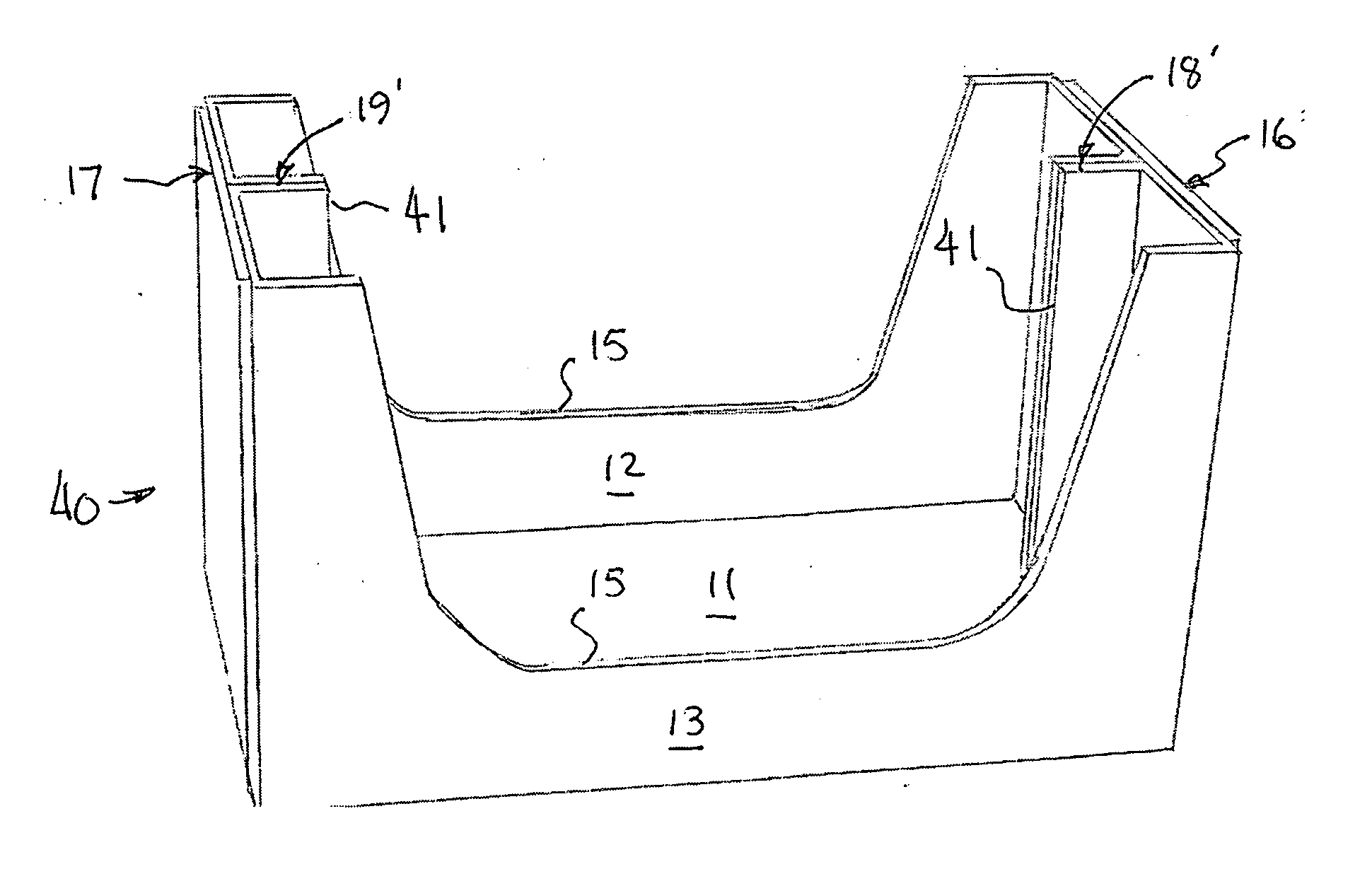

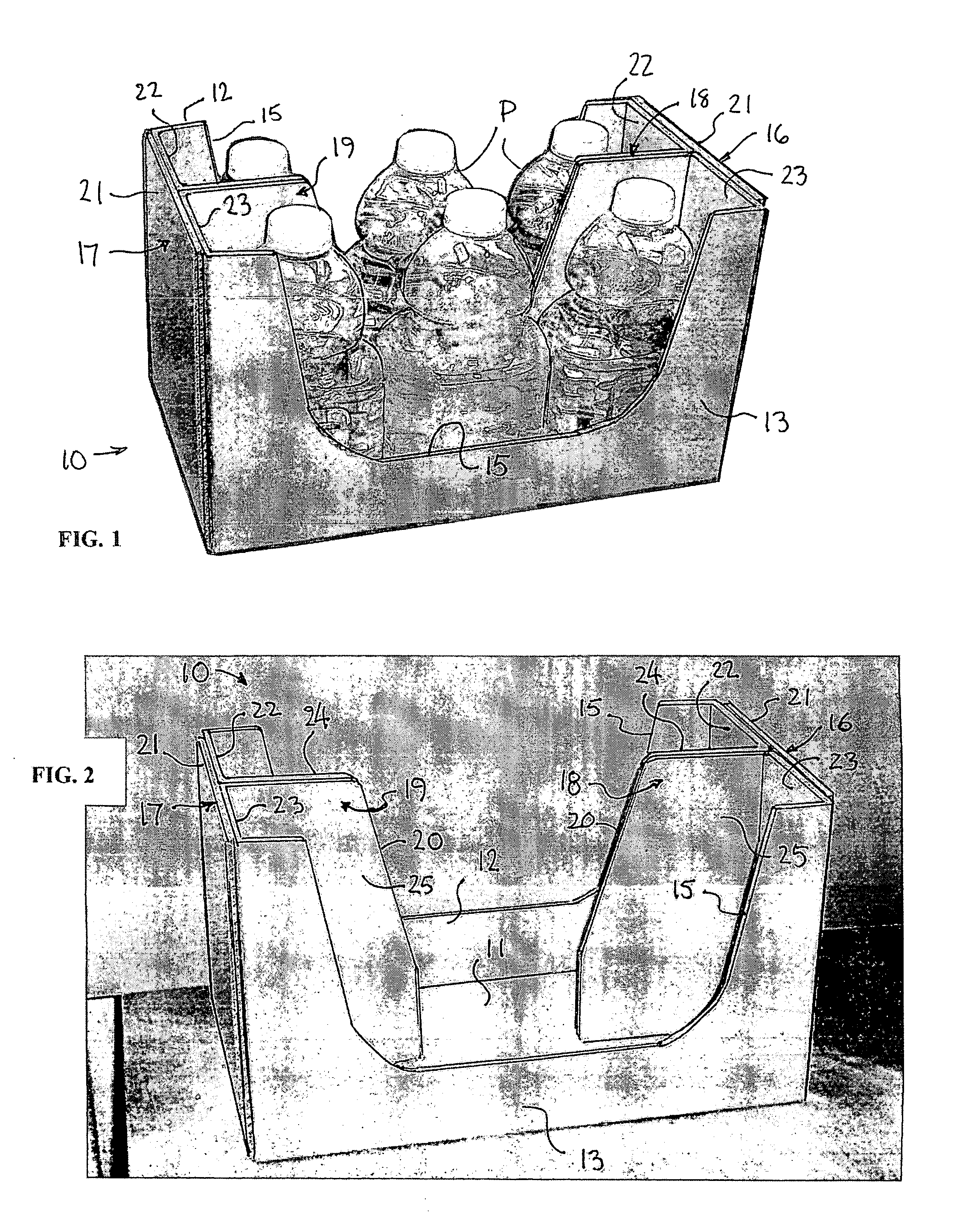

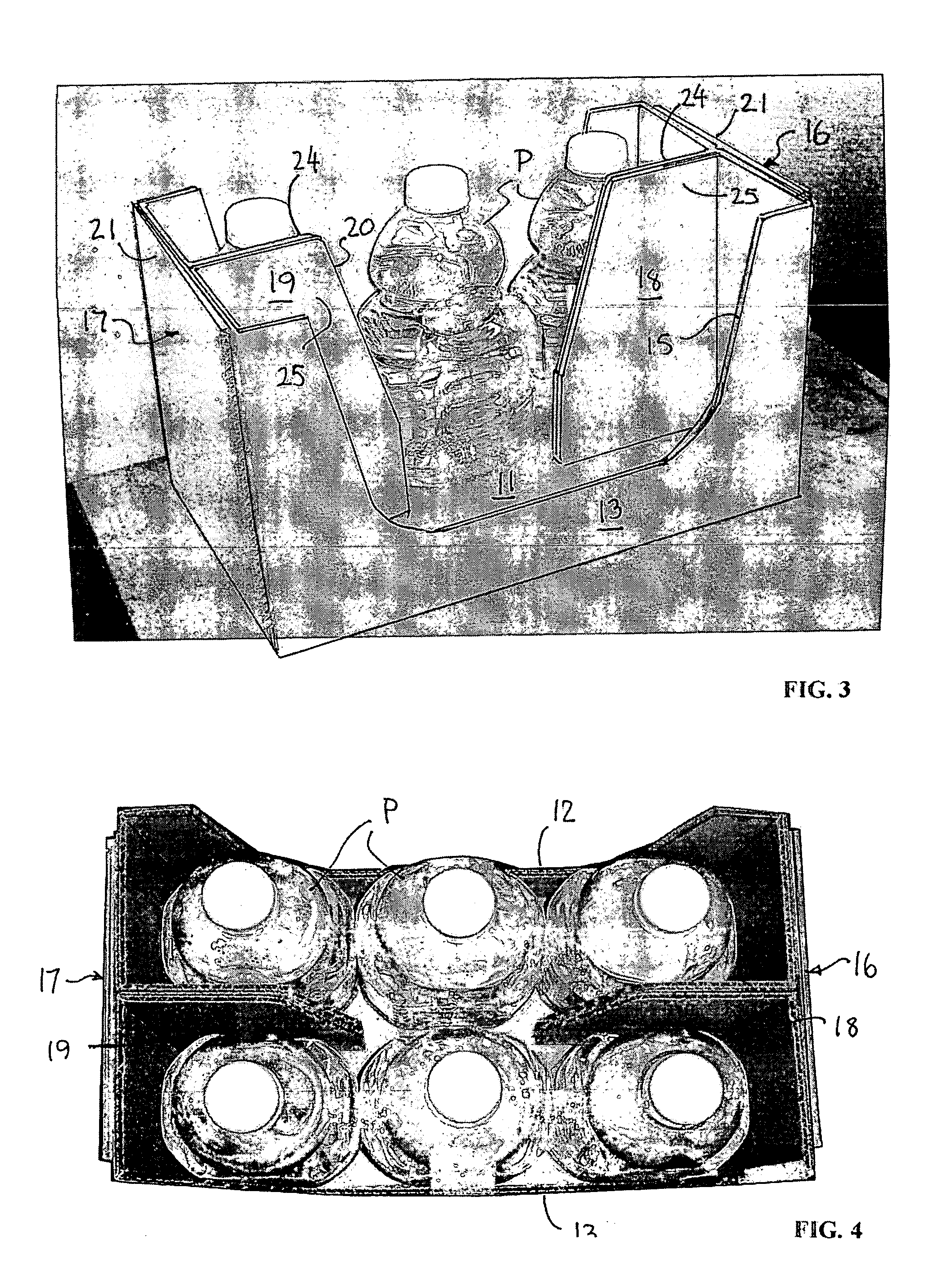

[0029] the tray according to the invention is represented generally at 10 in FIGS. 1-4. The tray comprises a tray bottom portion having a bottom wall 11, opposite side walls 12 and 13 with large cut-out areas 15, and opposite end walls 16 and 17, and reinforcing divider panels 18 and 19 extending a short distance inwardly of the tray toward one another from the middle of the end walls. In this embodiment, each divider panel extends over approximately one-third the length of the tray, and has a sloping inner edge 20 so that the panels are narrower at their top than at their bottom.

[0030] The end walls each comprise an outer end wall panel 21 folded upwardly from opposite end edges of the tray bottom wall, and end wall flaps 22 and 23 extending inwardly from opposite ends of the respective side walls. The end wall flaps each extend approximately one half the width of the respective end wall, and lie inside the end wall panels and are glued thereto. The end wall panels and end wall fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com