Vacuum cleaner having two cyclonic cleaning stages

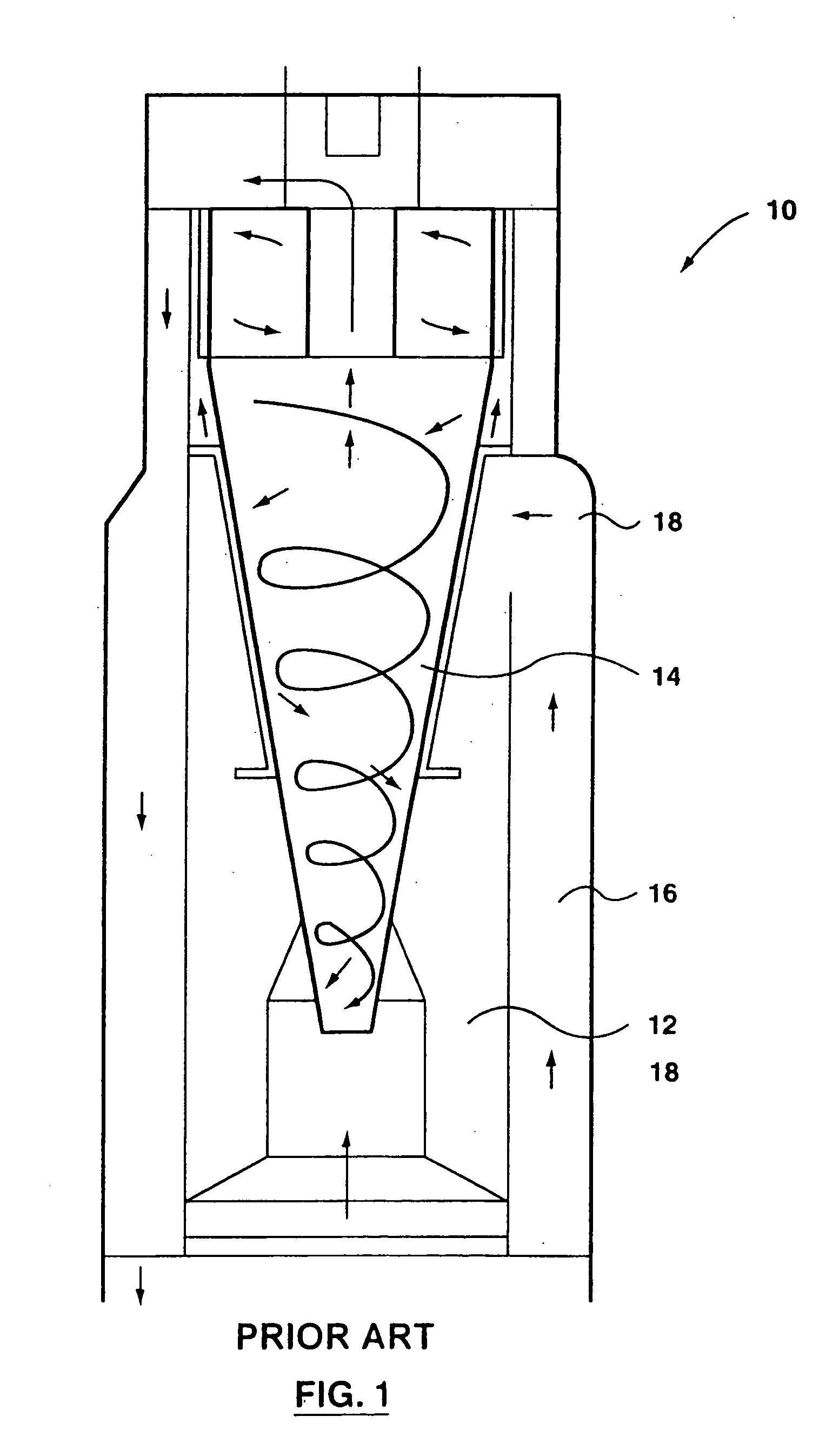

a vacuum cleaner and cyclonic technology, applied in the field of vacuum cleaners, can solve the problems of turbulent pressure loss, difficult to clear blockages, increase the cost and complexity of the product manufacturing,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

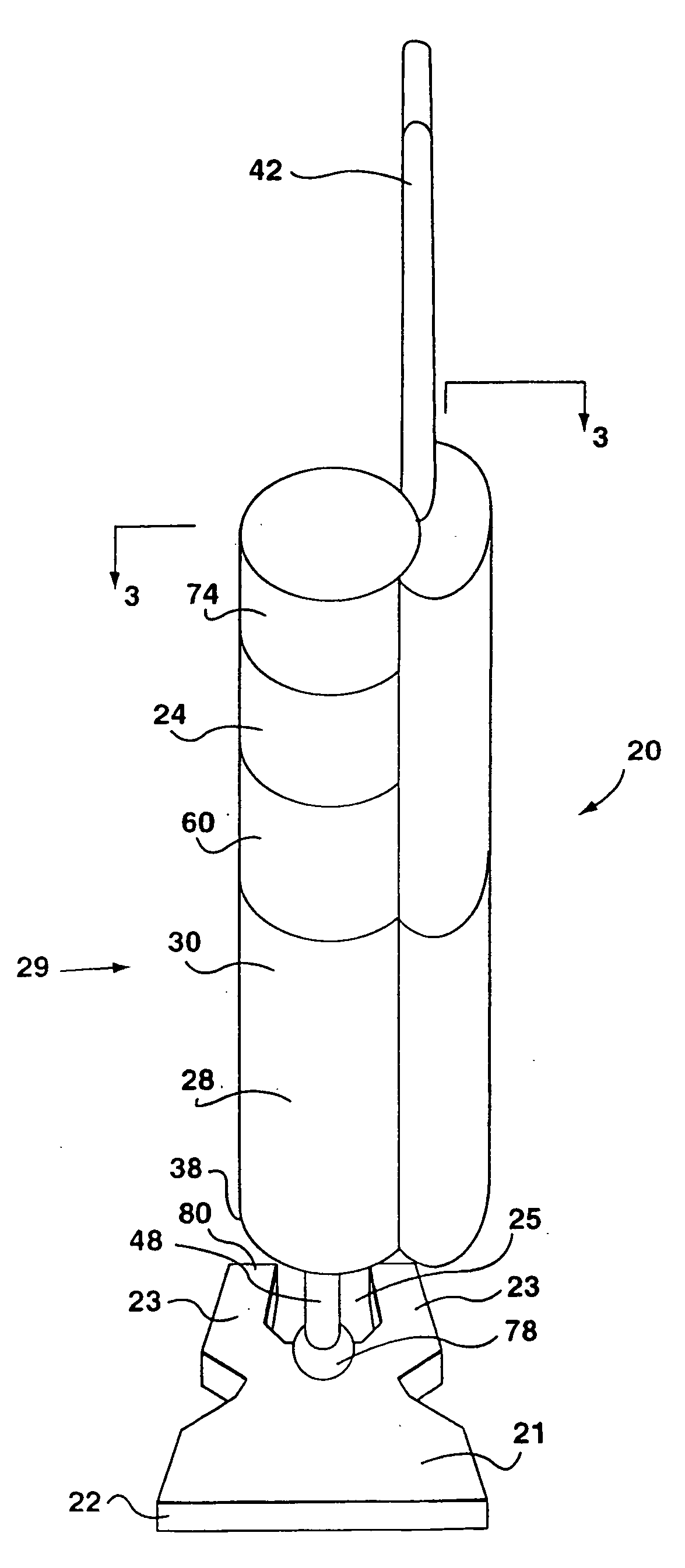

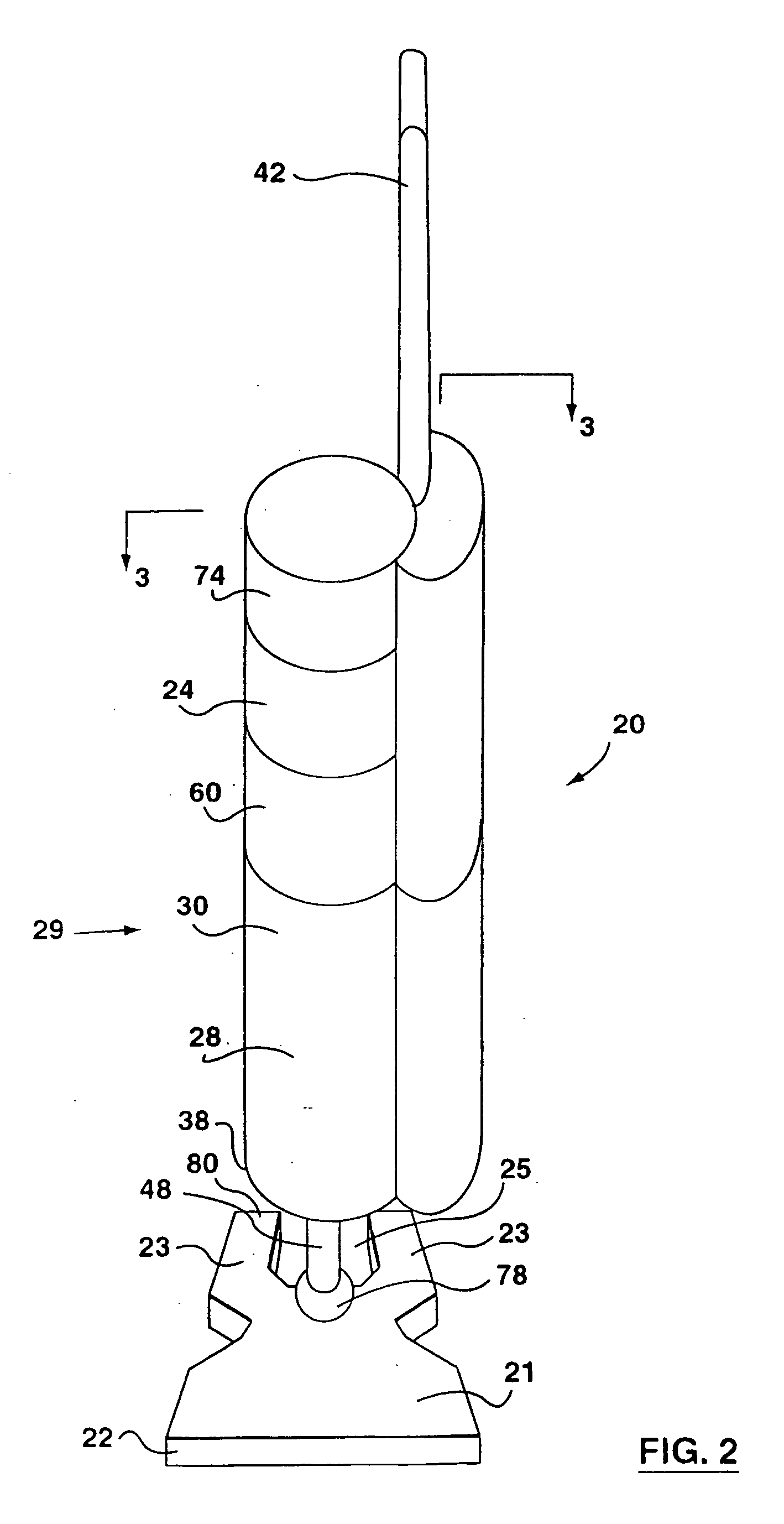

[0048] An upright cyclonic vacuum 20 according to the present invention is shown in the FIGS. 2 and 3. A floor cleaning head 22 is provided at the lower end of vacuum cleaner 20. Head 22 comprises a forward portion 21 and two rear portions 23 extending rearwardly from the forward portion 21. Rear portions 23 are spaced apart and define a space 25 there between. Head 22 has a dirty air inlet 27 which is positioned in forward portion 21 and, preferably, adjacent the front end of forward portion 21 (see FIG. 3). Preferably, head 22 also comprises a transversely extending, floor-contacting rotating brush member 26 which is mounted for rotation in head 22. A handle 42 and rear wheels 44 may be provided on head 22 to facilitate movement of the unit for cleaning of a floor, and the like. Head 22 may also incorporate a forward set of wheels (not shown) as is known in the art.

[0049] In order to be able to convert the vacuum cleaner for above the floor cleaning, handle 42 may be hollow and b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com