Device for retaining panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is an improvement of the rack disclosed in U.S. application Ser. No. 10 / 798,452 filed Mar. 12, 2004 by the applicants of the present application, which is incorporated herein by reference.

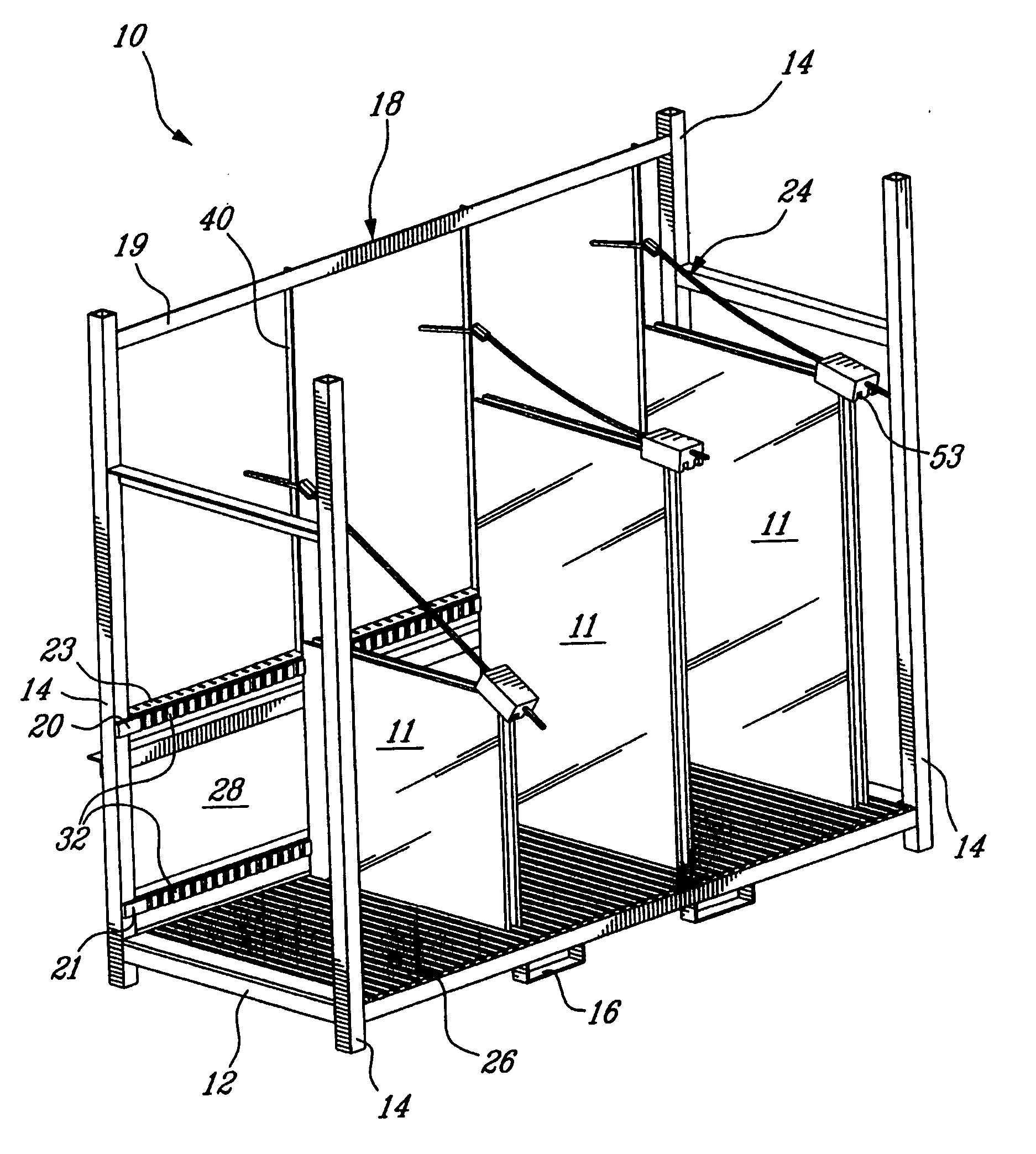

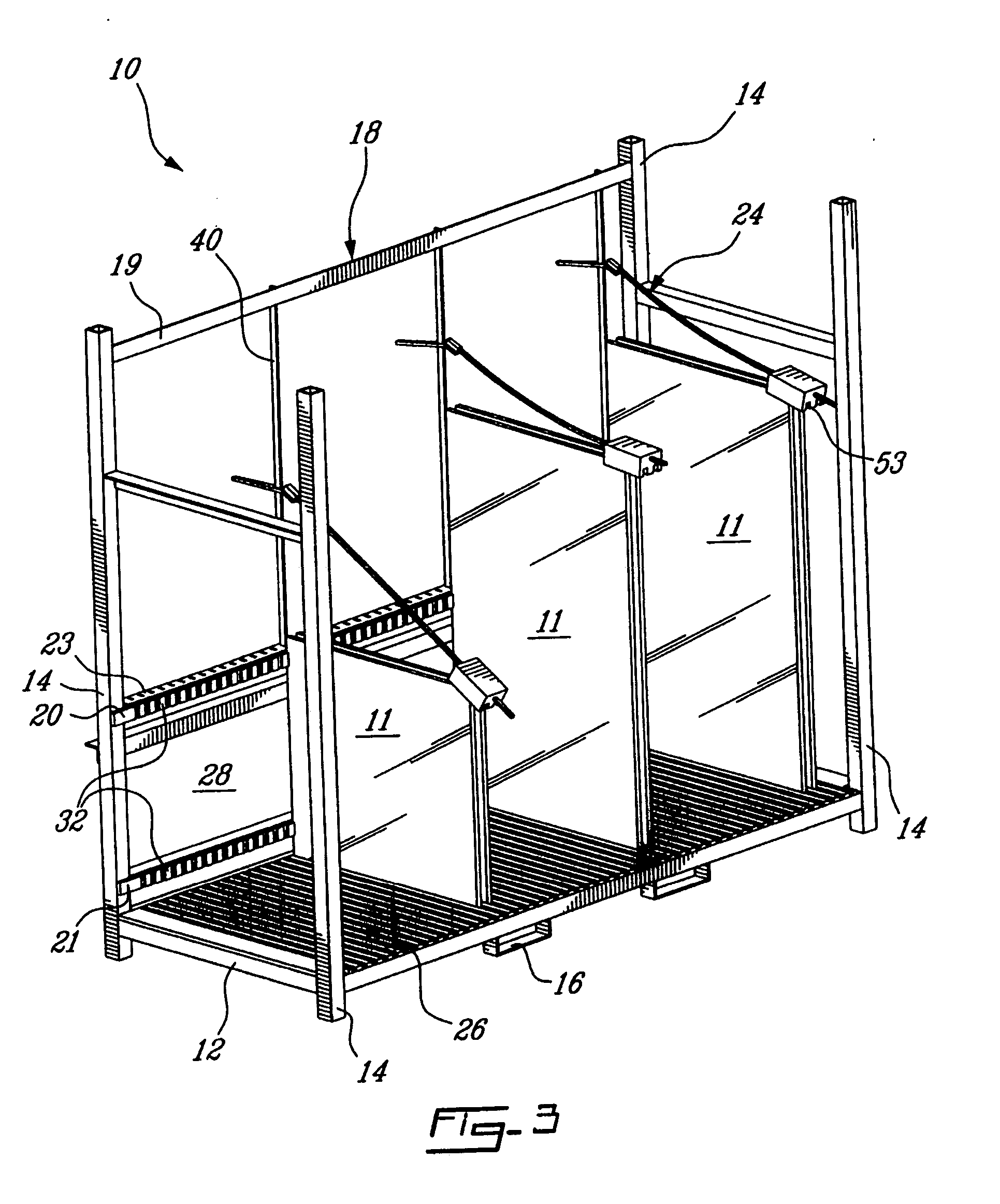

[0020] Referring to FIG. 3, a preferred embodiment of a rack for holding panels 11 such as glass sheets or sealed glass panel units is generally indicated at 10. The rack 10 comprises a base 12 supported by four (4) vertical posts 14. The vertical posts 14 are preferably tubular members having a square cross-section. Loop members 16 are provided under the base 12 to be engaged by a fork of a lift truck such as to ease the handling of the rack 10. Two (2) of the vertical posts 14, located at the rear side of the base 12, support a rear structure 18 extending vertically from the base 12.

[0021] The rear structure 18 comprises first, second and third horizontal bars 19,20,21 as well as a vertical plate 28, which all extend between the rear vertical posts 14. The horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com