Easy open pouch with energy activation

a technology of energy activation and pouches, applied in the field of flexible packaging, can solve problems such as tear lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

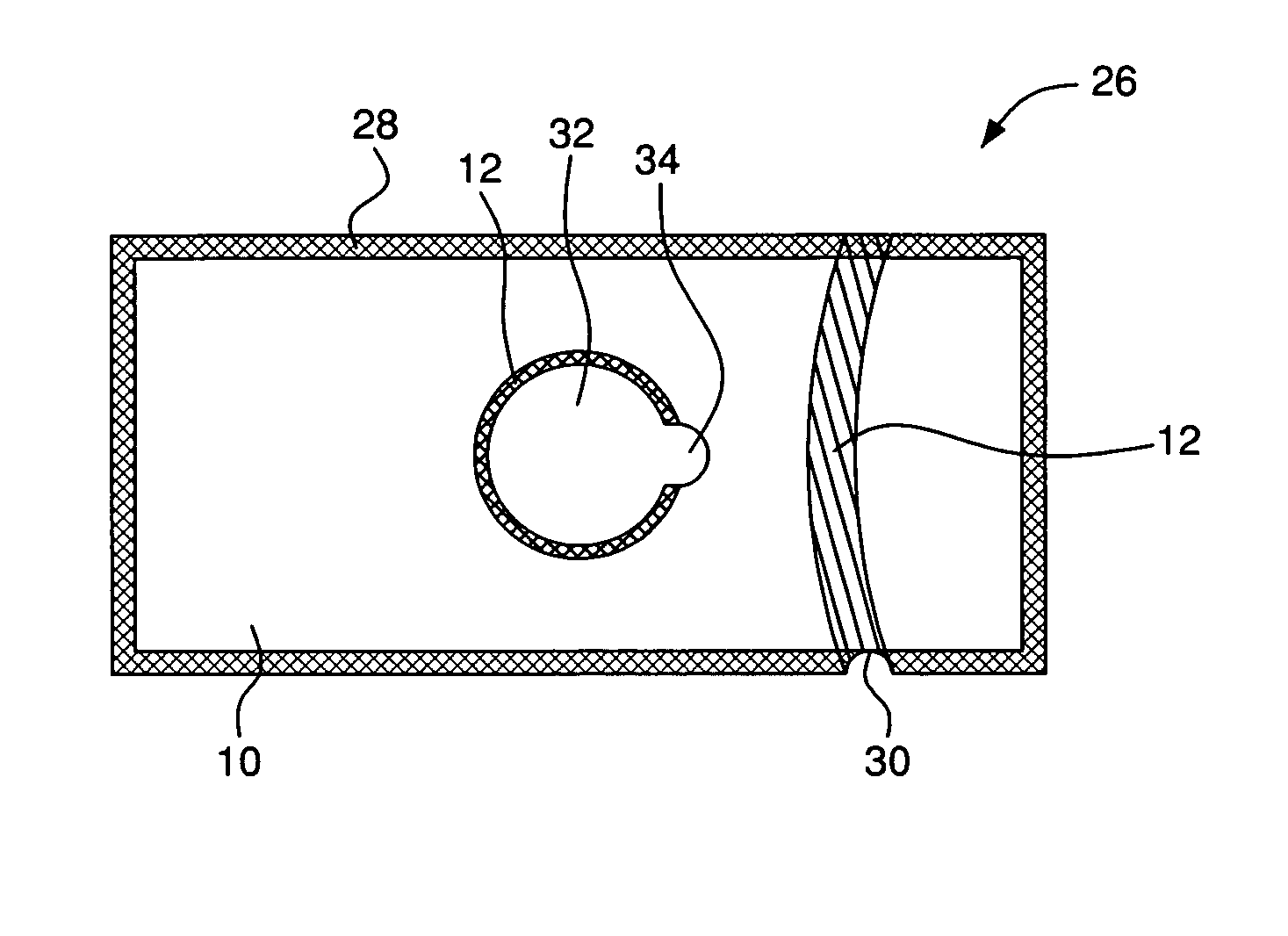

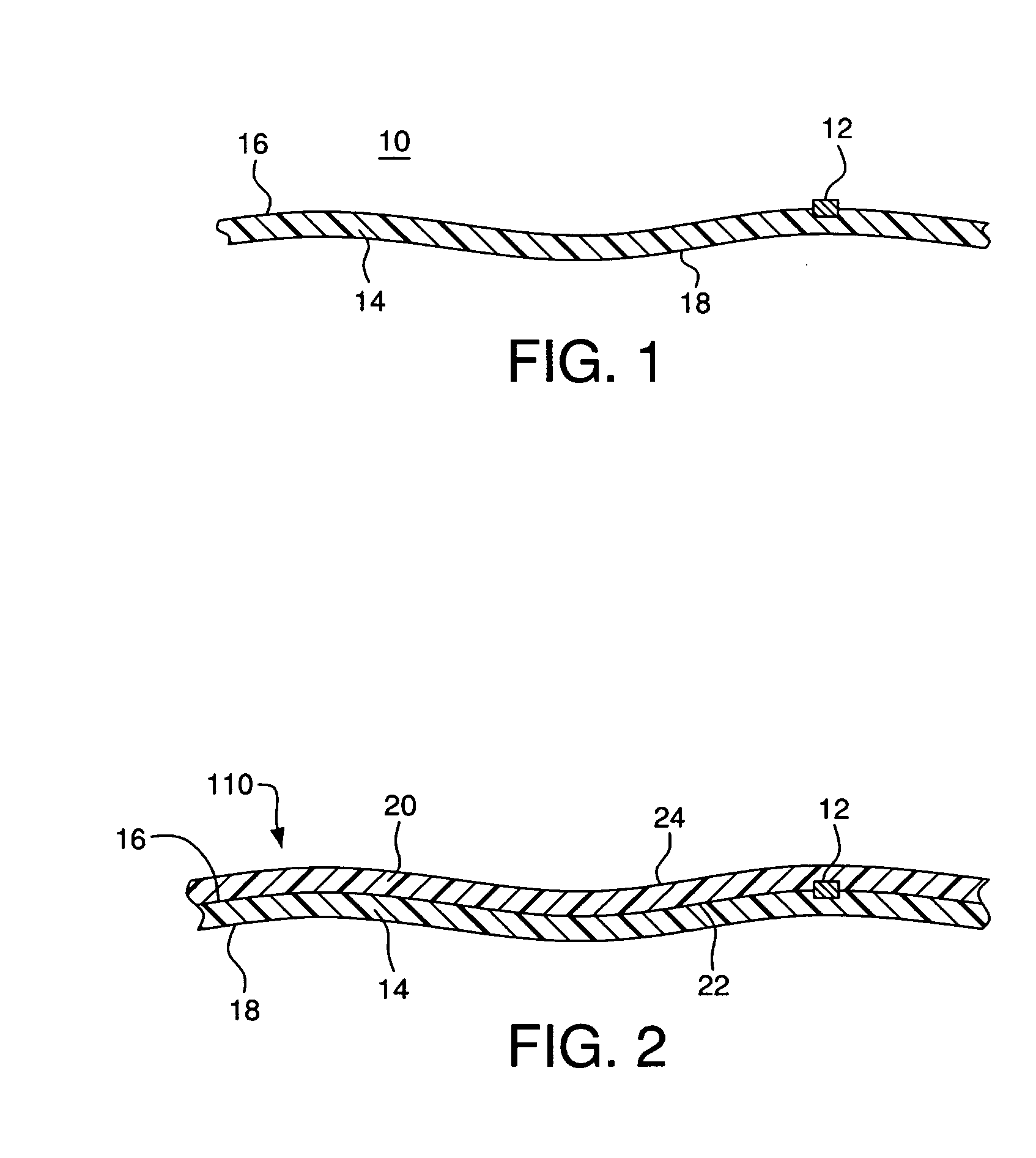

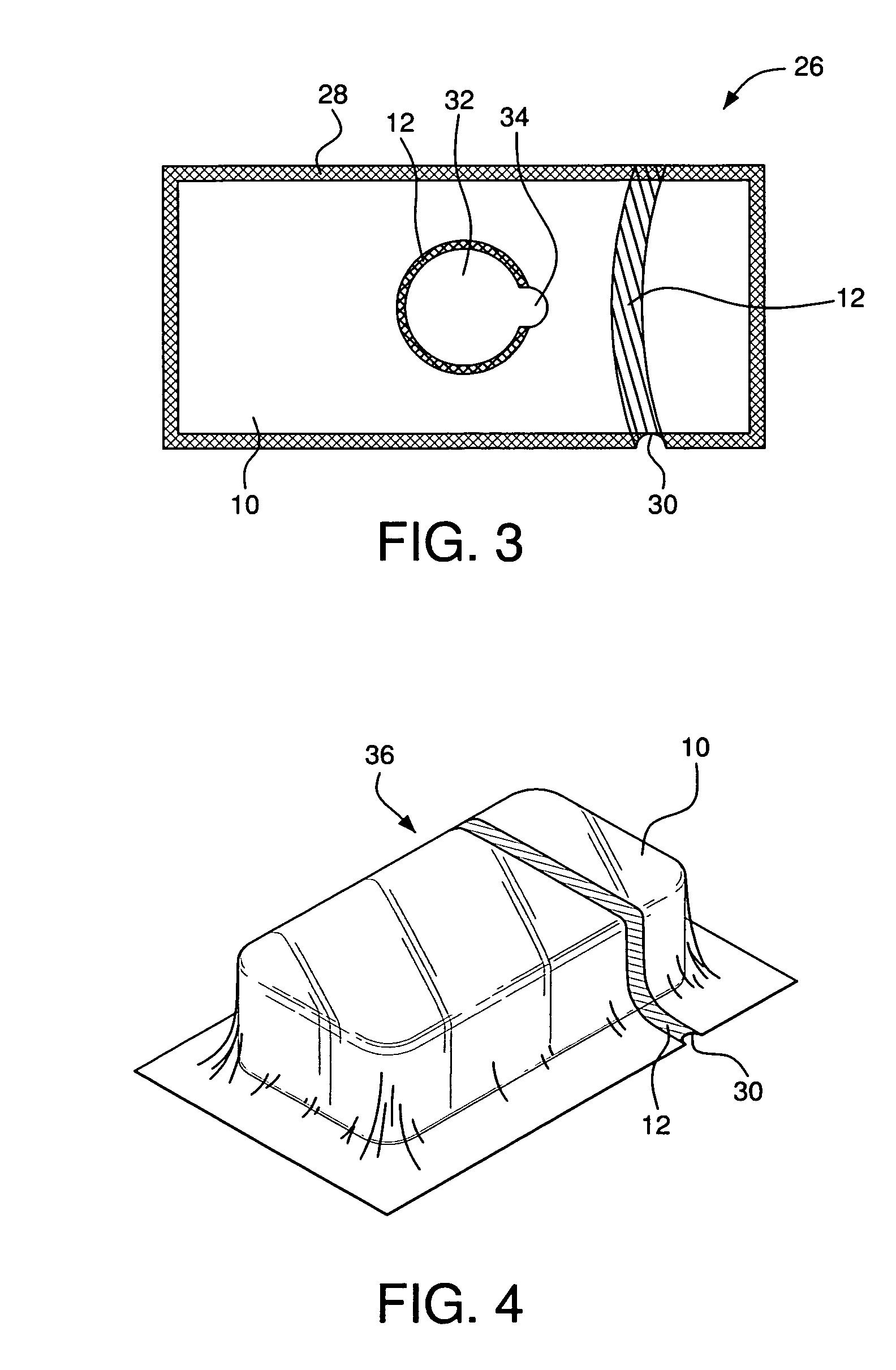

[0012] In the drawings, where like numerals identify like elements, there is shown in FIG. 1 a sheet of flexible packaging material, which is generally designated by the numeral 10. As used herein, the term “sheet of flexible packaging material” includes materials used in the manufacture of flexible packages (e.g., candy wrappers) and materials used in covering and / or sealing rigid or semi-rigid containers (e.g., microwavable dinner containers).

[0013] As shown in FIG. 1, the sheet 10 includes a first film layer 14 having an outer side 16 and an inner side 18. The sheet 10 further includes a pattern of particles 12 on the outer side 16 of the film 14. The particles 12 are dosed with or exposed to an energy source so as to create heat and to penetrate into the surface of the outer side 16 of the film 14. The heated penetration of the particles 12 into the film 14 weakens the film 14, creating a “tear line”. This weakened area of the film is defined herein as a “tear line” regardless ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| radio frequency | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com