Modular laundry system with horizontal module spanning two laundry appliances

a laundry system and laundry appliance technology, applied in the field of modules, can solve the problems of small laundry area, inefficient, inconvenient operation, etc., and achieve the effect of not optimizing the laundry area for performing functions, reducing labor intensity, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

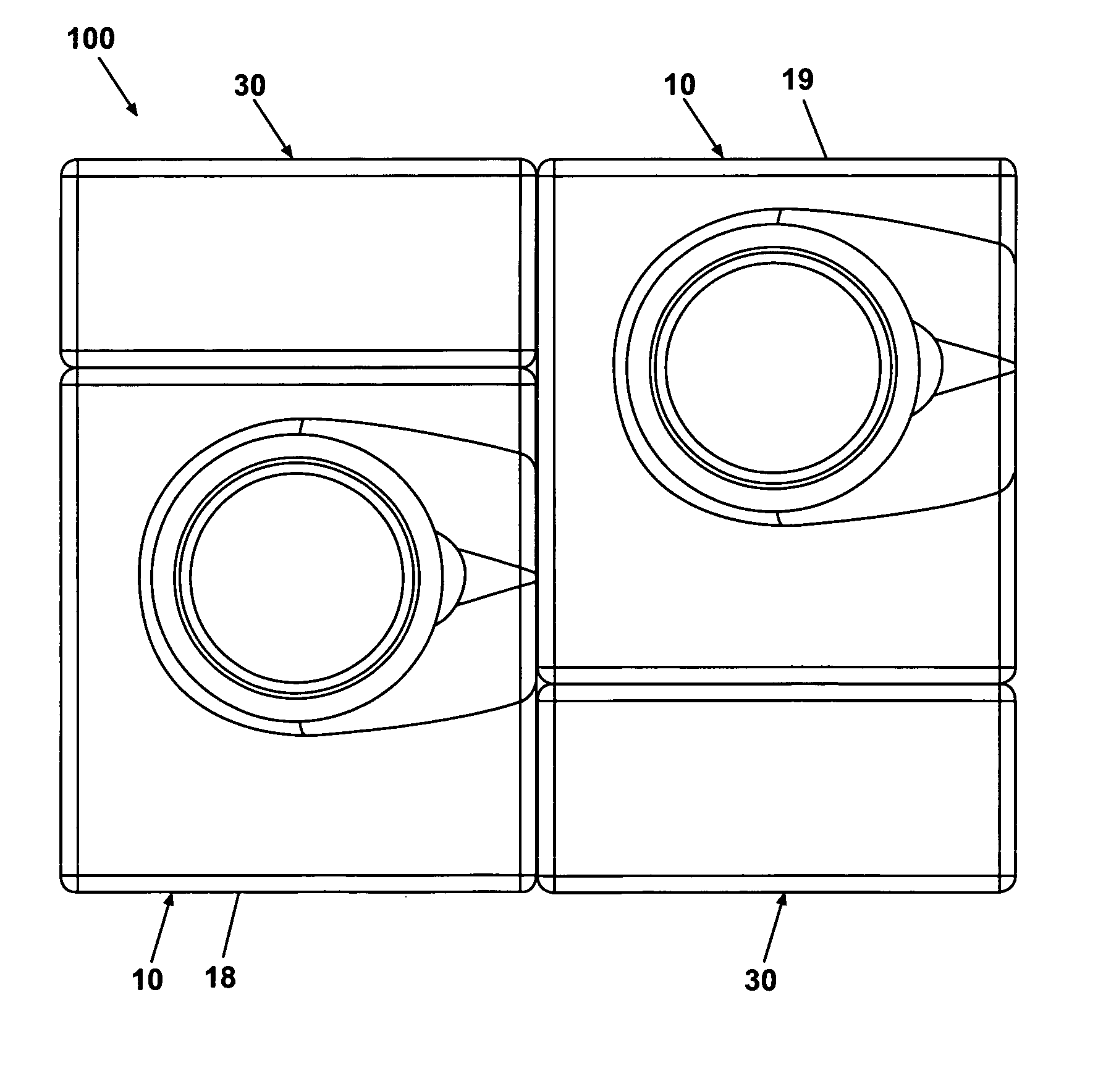

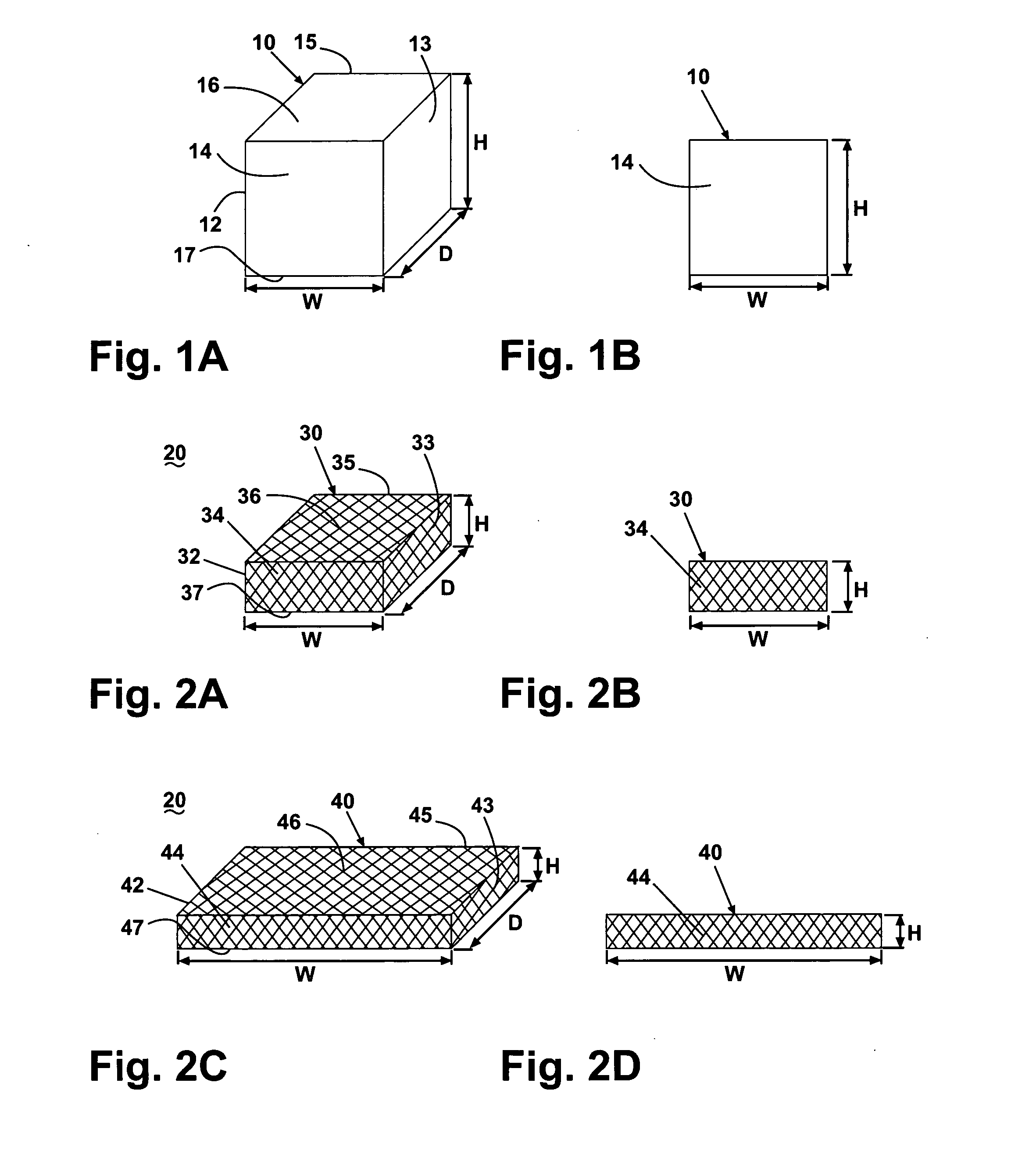

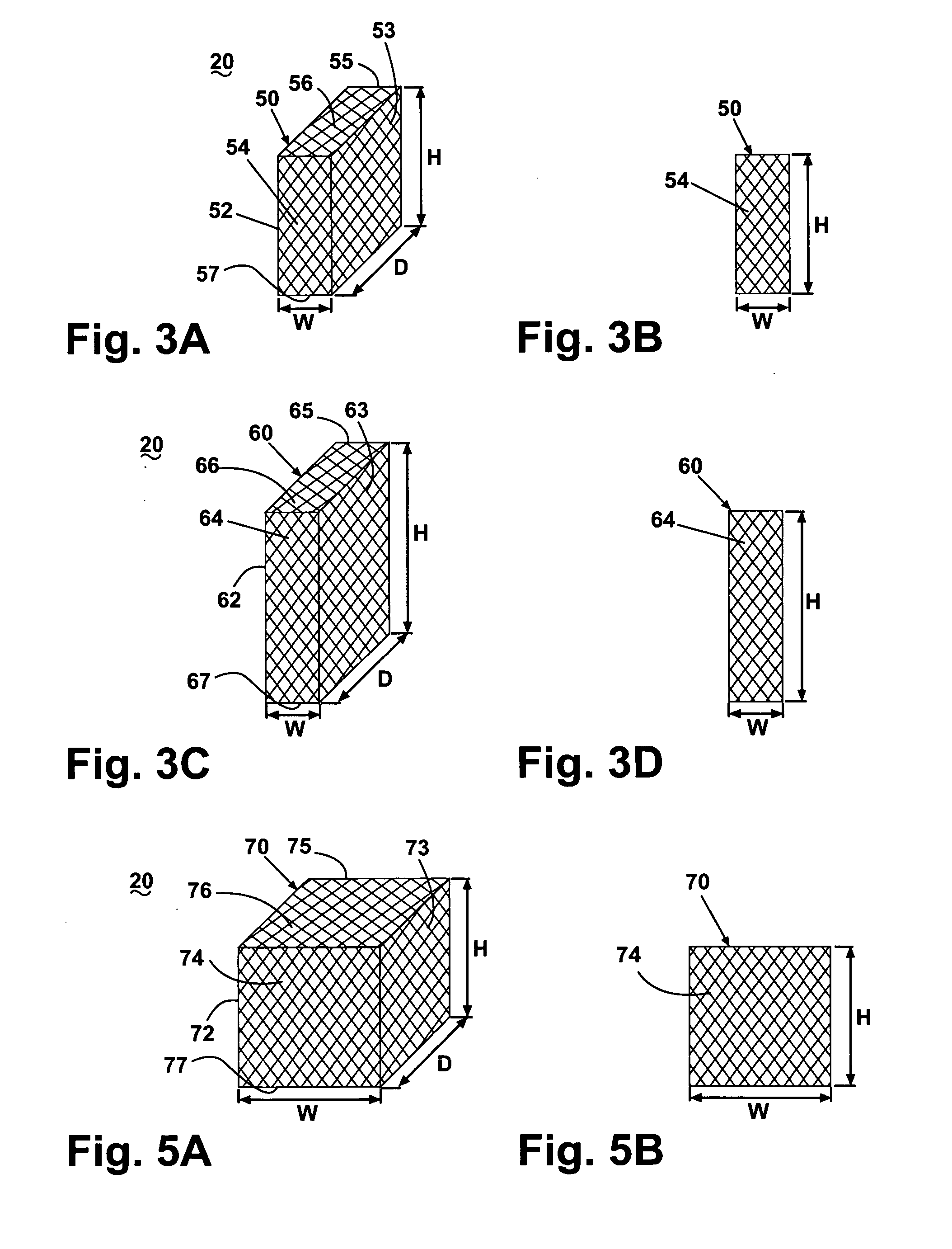

[0152] A modular laundry system according to the invention comprises at least one laundry appliance 10 and at least one module 20. According to one embodiment of the invention, the laundry system comprises two laundry appliances 10 and at least one module 20, which can be selected and configured to provide desired laundry care functionality within a given laundry area. The laundry area is a space of a home in which the laundry appliance 10 conventionally resides. The laundry area can be, for example, a dedicated laundry room, a shared room, such as a combined laundry and utility room or a combined laundry room and garage, a closet, or part of another room or hallway of the home.

[0153] The laundry appliance 10 is a conventional appliance for washing and drying fabric items, such as clothes and linens. Examples of the laundry appliance include, but are not limited to, a washing machine, including top-loading, front-loading, vertical axis, and horizontal axis washing machines, a dryer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com