Sound Attenuation Enclosure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

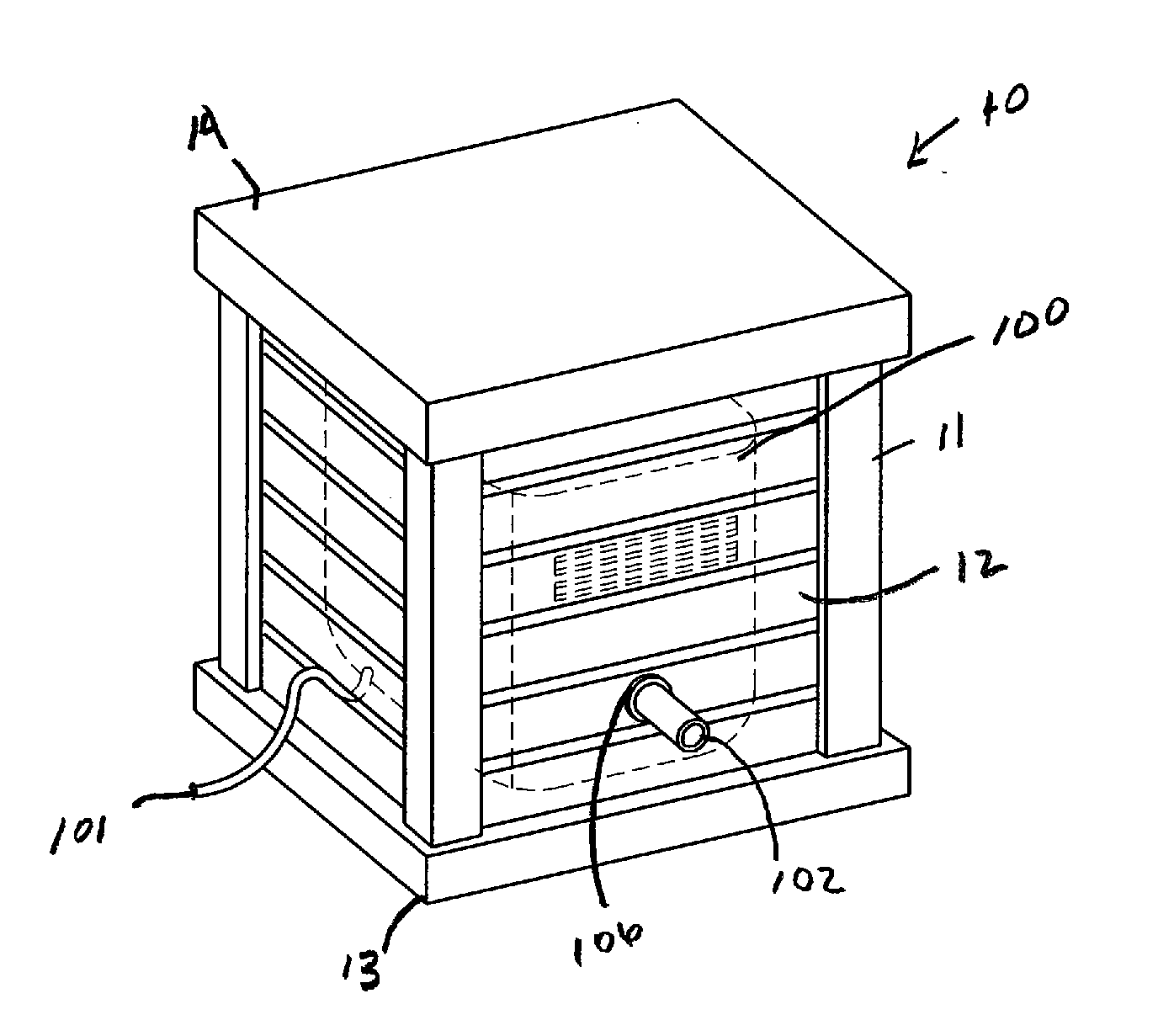

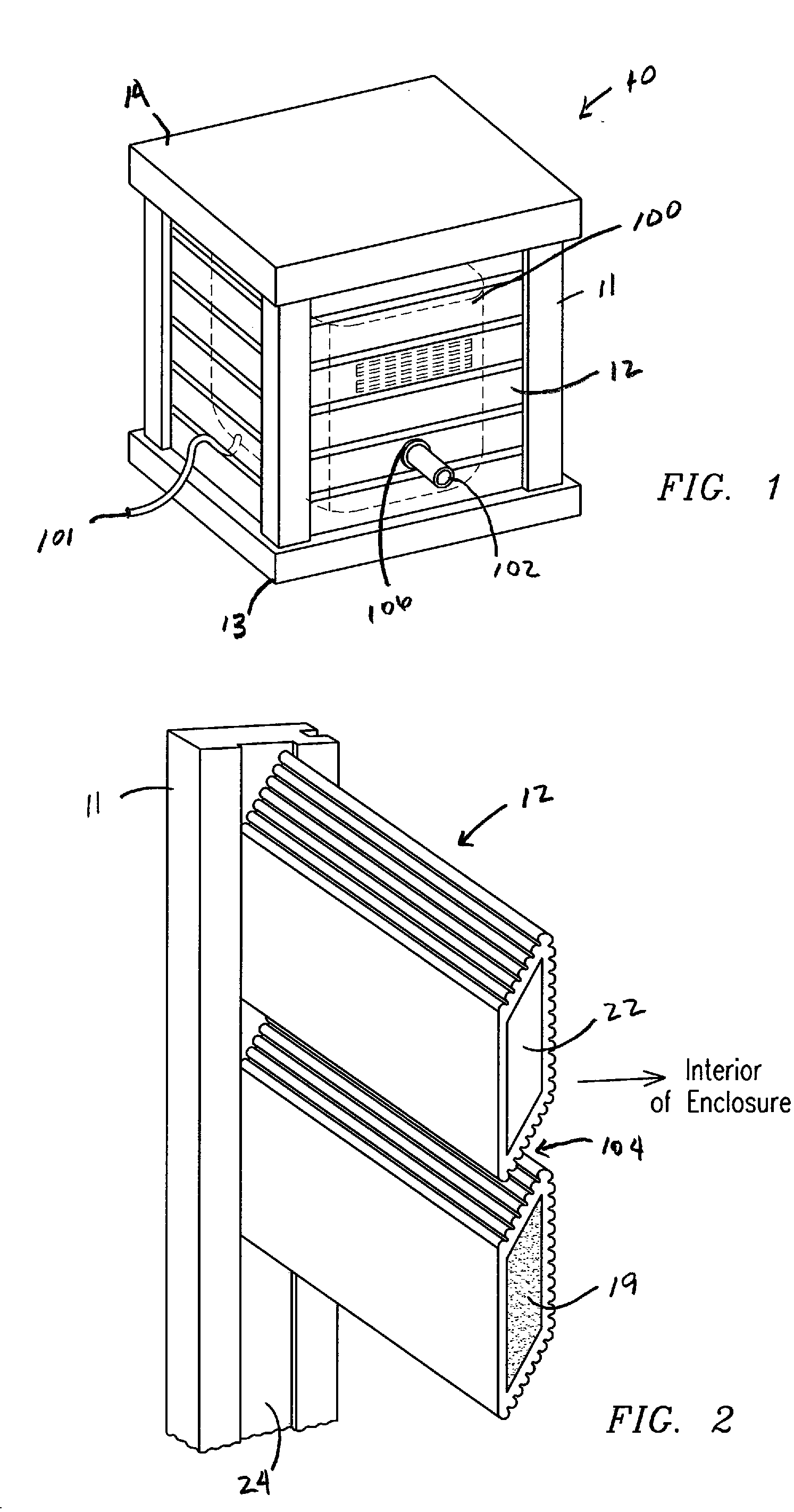

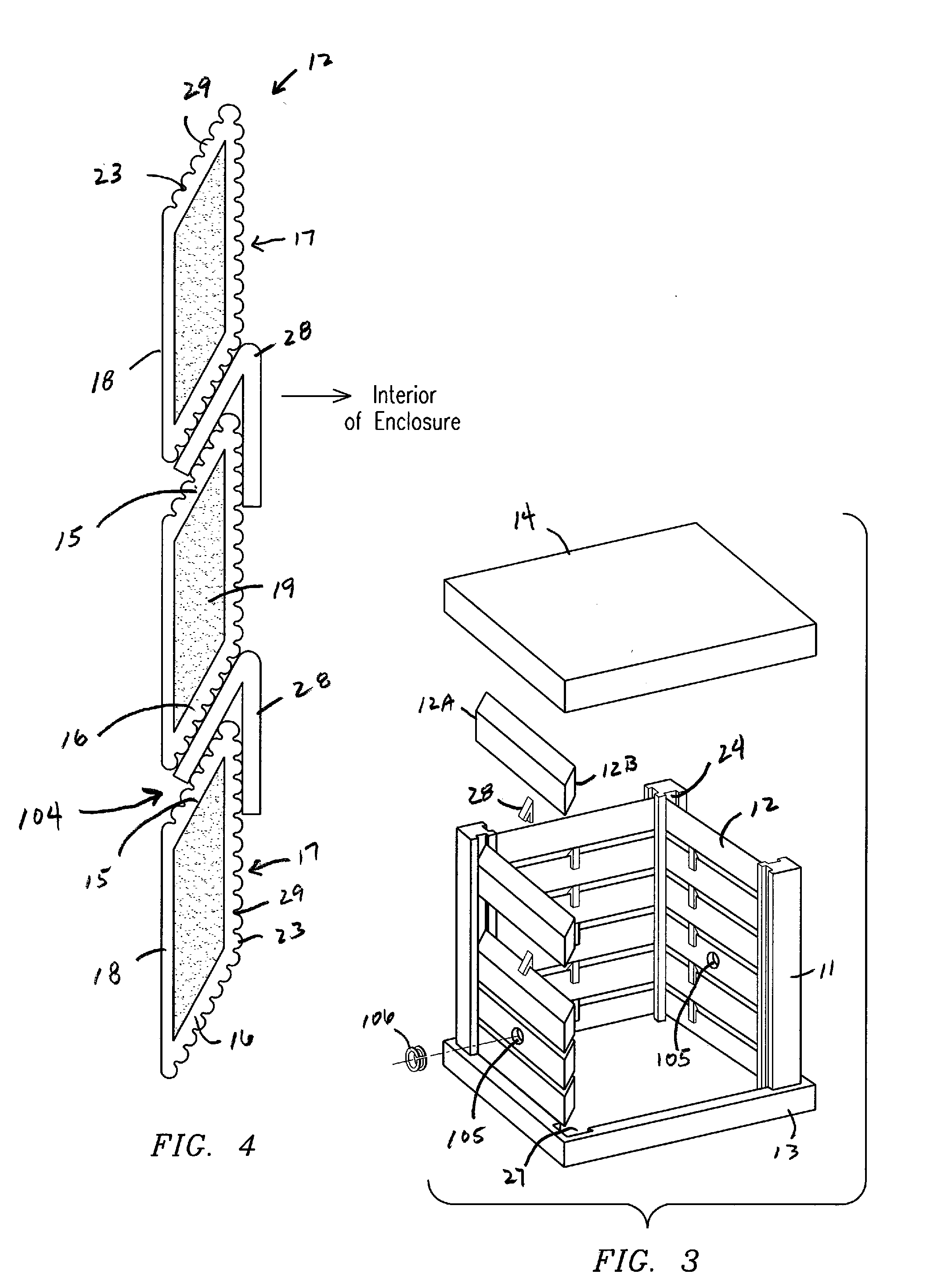

[0033]A first embodiment of the present invention for a sound attenuation enclosure is illustrated in FIGS. 1 through 4. The enclosure 10 comprises a plurality of sound insulating panels 12 attached to and supported on support columns 11. One or more of the panels 12 has a shell-like, or tubular, configuration having an inner chamber 22 filled with a sound retardant material 19. The columns 11 may also have a similar configuration for retaining the sound retardant material 19.

[0034]Various sound retardant materials are acceptable, including, but not limited to, rubber, polymer foam, water, gravel, sand, or other dense materials used for sound attenuation. In some instances, the panels 12 and / or columns 11 may not contain the sound retardant material, and the components remain hollow. Alternatively, the panels 12 may be fabricated as a solid piece of sound retardant material, and not have a chamber 22.

[0035]The panels 12 and columns 11, and those similar components described in all e...

Example

[0049]A second embodiment of the enclosure 10 illustrated in FIGS. 5, 6 and 7, includes panels 32 supported in spaced relation to one another by columns 31. The panels 32 include a first set 32A and a second set 32B spaced laterally from the first set 32A toward an exterior of the enclosure. In each set 32A and 32B, adjacent panels 32 are spaced apart forming a gap 33 between consecutive panels 32. However, the panels 32 in the first set 32A are positioned with respect to the panels 32 of the second set 32B so that the first set 32A covers at least a portion of the gaps 33 between consecutive panels 32 in the second set 32B. Similarly, the second set 32B is positioned with respect to the first set of panels 32A so that second set of panels 32B covers at least a portion of the gaps 33 between consecutive panels in the second set 32B.

[0050]The panels 32 shown in FIG. 7 have the inclined sections 15 and 16 as in the above-described first embodiment. However, other shapes may be used. F...

Example

[0054]A third embodiment of the enclosure is illustrated in FIGS. 8A, 8B, 9 and 10, also includes a similar “staggered” panel configuration as in the second embodiment; however, columns are not necessary to arrange the panels to form an enclosure. More specifically, the enclosure 10 includes panels 41 including a first set of panels 41A and a second set of panels 41B. The first set of panels 41A includes a plurality panels that are spaced apart forming a gap 43 between each consecutive pair of panels 41. The second set of panels 41B are laterally spaced from the first set of panels 41A toward an exterior of the enclosure 40. Panels from the first set 41A cover at least a portion of the gaps 43 between the panels of the second set 41B; and, panels from the second set 41B cover at least a portion of the gaps 43 between the panels of the first set 41A.

[0055]As shown in FIG. 9, the panels of the first set 41A and second set 41B are the same length. Two notches 44 are formed in each pane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com