Swimming pool cleaning vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

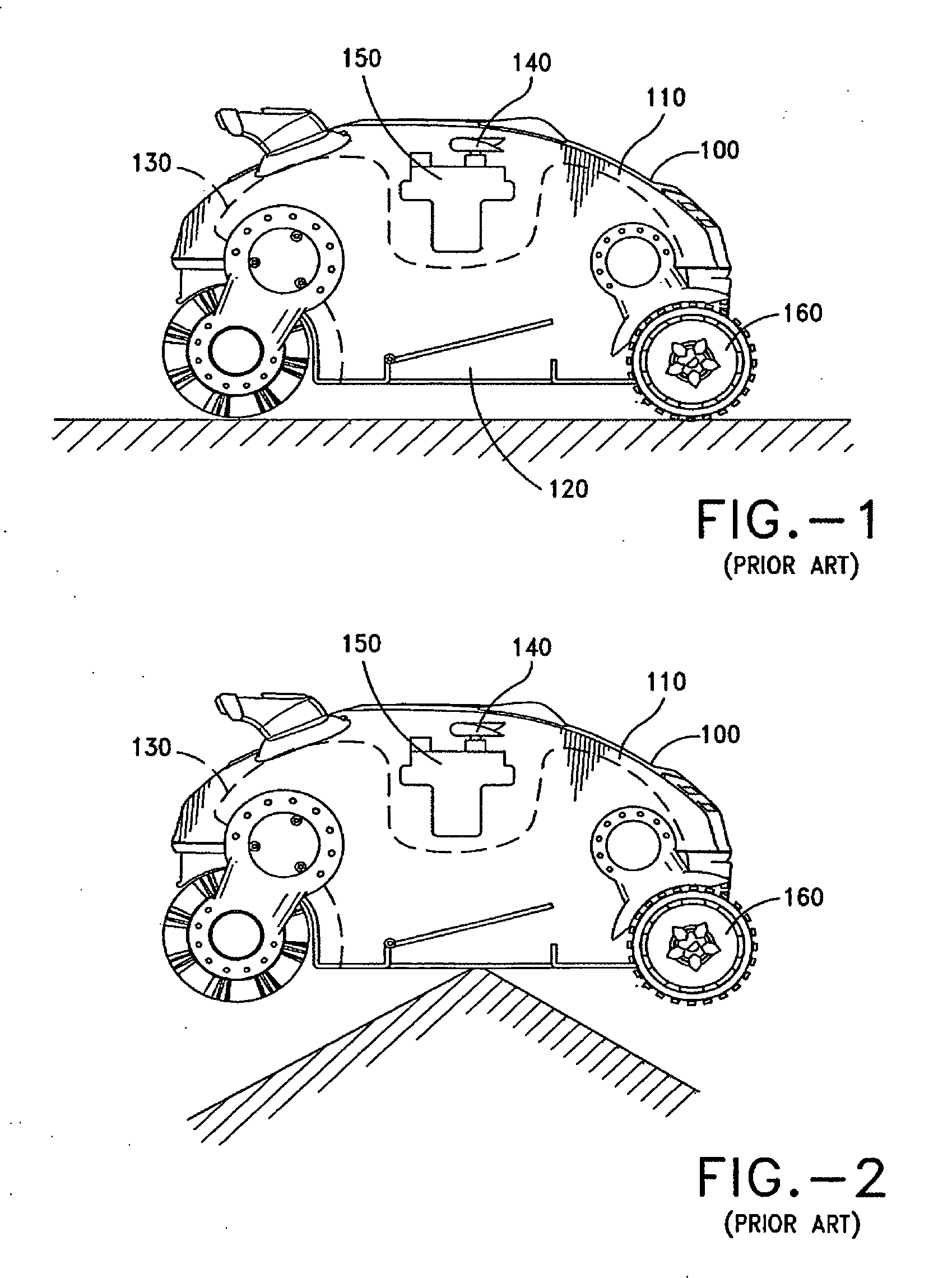

[0027]To explain the objects and advantages of the swimming pool cleaning vehicle in accordance with the invention, the following description of the drawing and the exemplary embodiments are provided in detail. As will be appreciated by those skilled in the art, the exemplary embodiments are provided to explain the swimming pool cleaning vehicle in accordance with the invention in detail and not to be used to limit its scope.

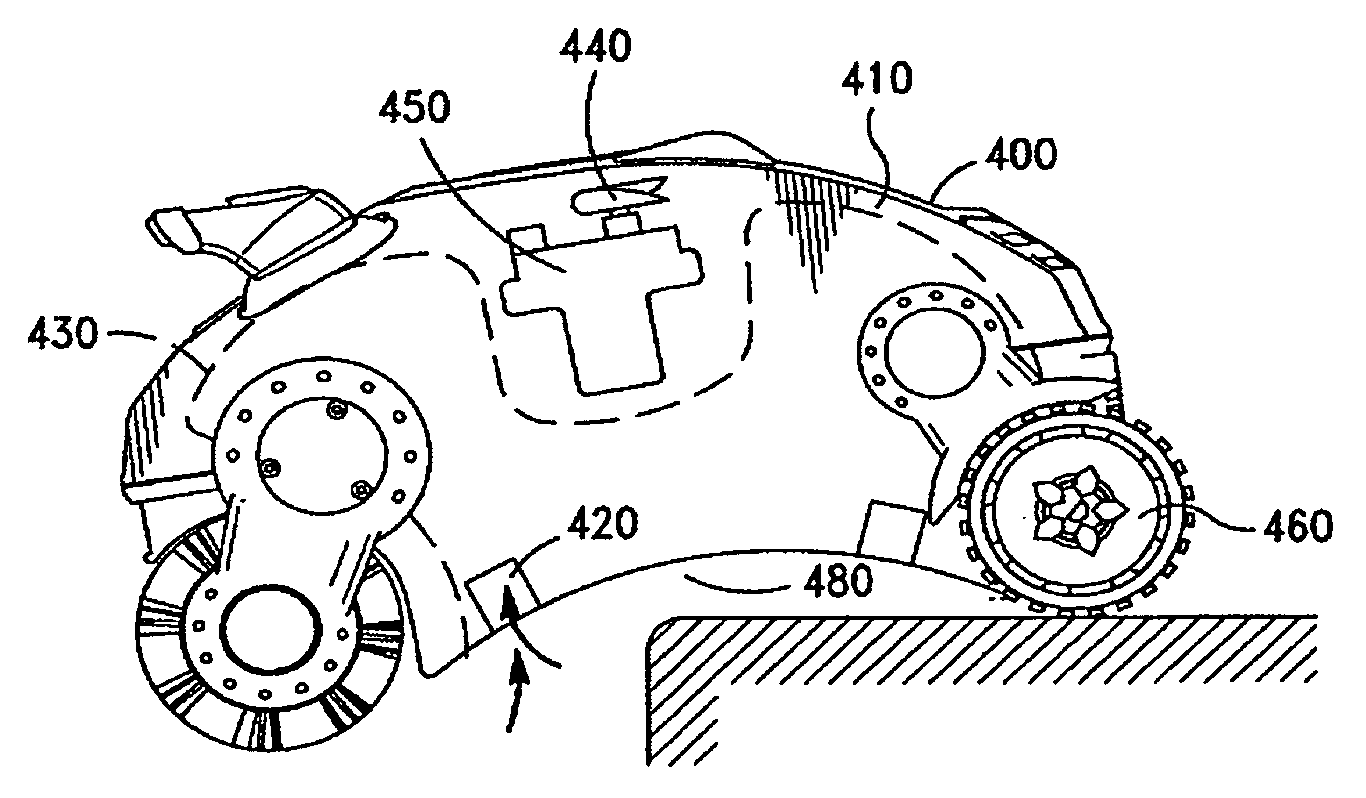

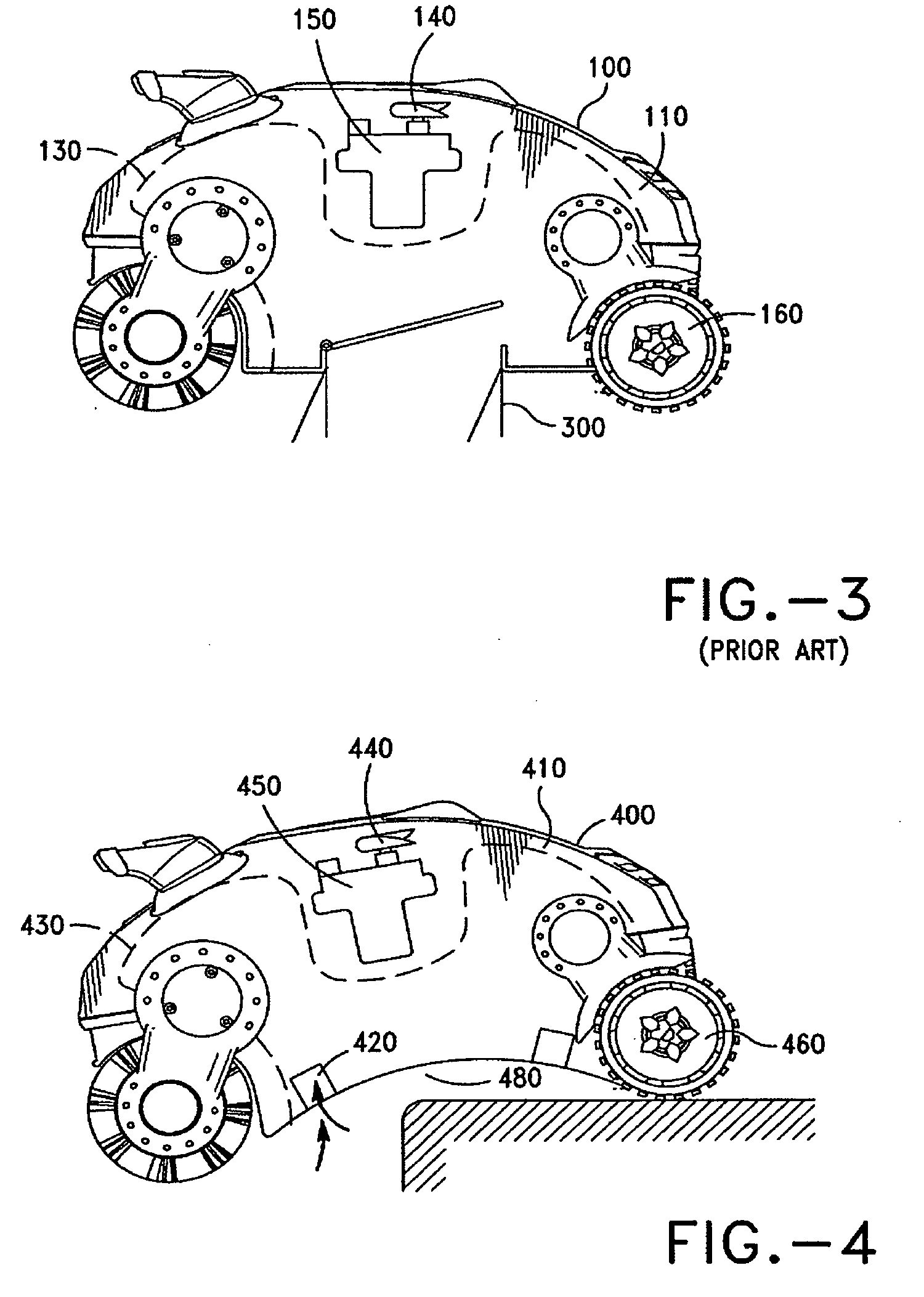

[0028]The swimming pool cleaning vehicle in accordance with the invention improves the art by providing a swimming pool cleaner with concave bottom to ensure the vehicle can easily overcome obstacles found on the pool surface. Additionally, by locating the water intake port adjacent to the vehicle's drive means, either using wheels and / or rollers water with dirt and debris is most likely to be sucked into the swimming pool cleaner interior and filtered.

[0029]FIG. 4 illustrates the construction of the swimming pool cleaning vehicle in accordance with the inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com