Material for fabrication of a kite or a wing and a kite or wing incorporating the material

a technology for kites and wing parts, applied in the field of kites and flying wings, can solve the problems of elongation or stretching of sufferers, difficult design and maintenance of kite aerodynamic properties, and the inability to re-launch ram air kites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

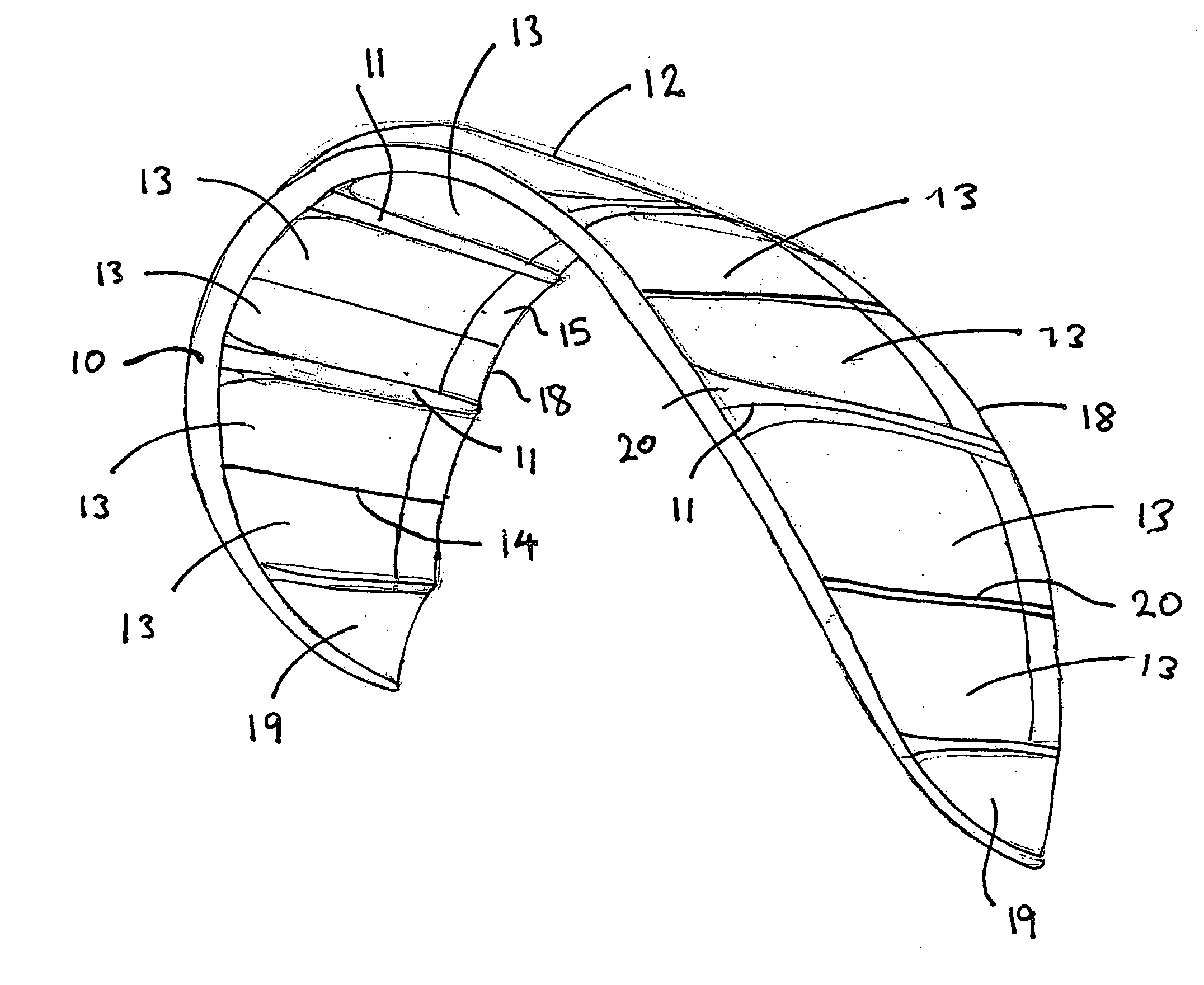

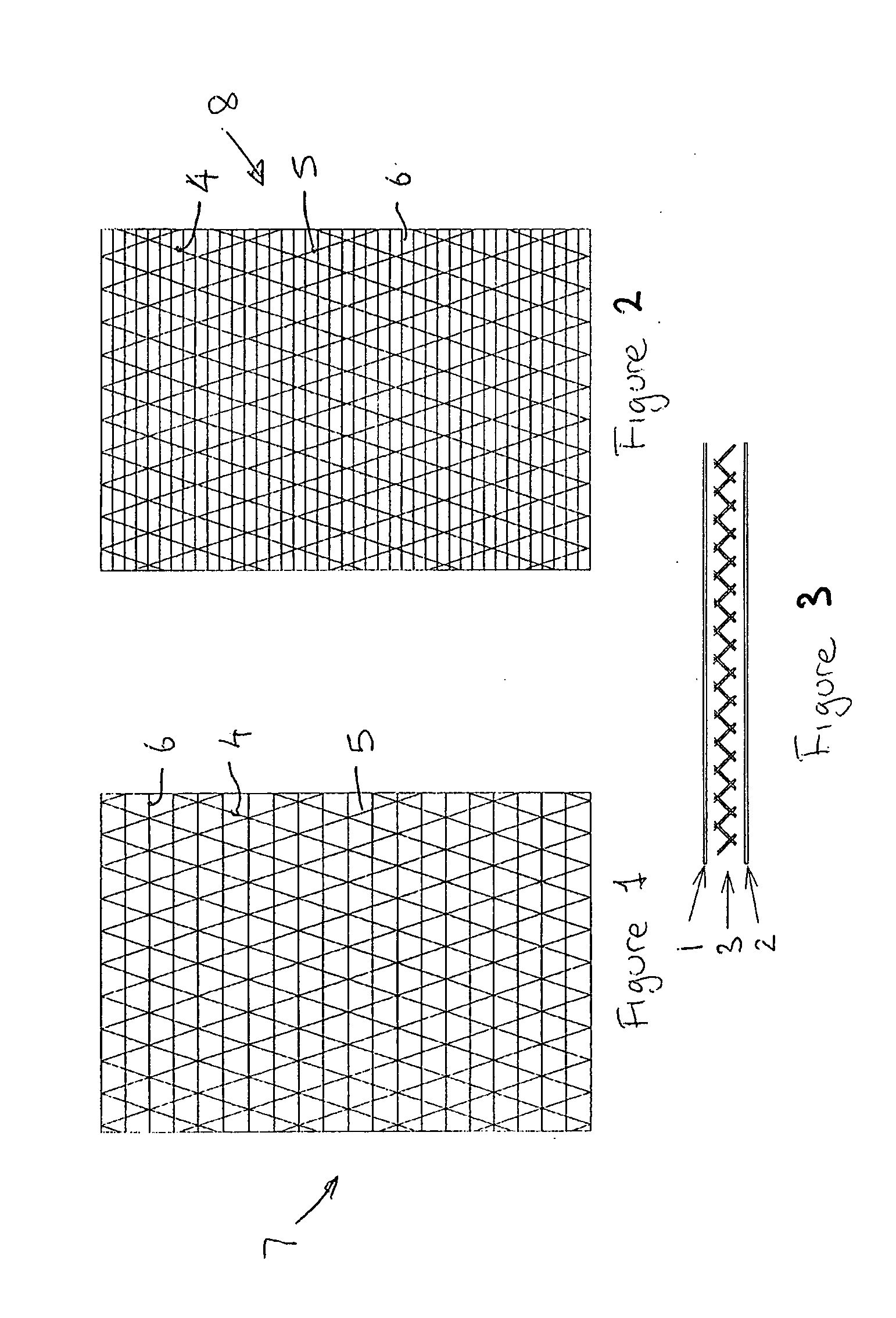

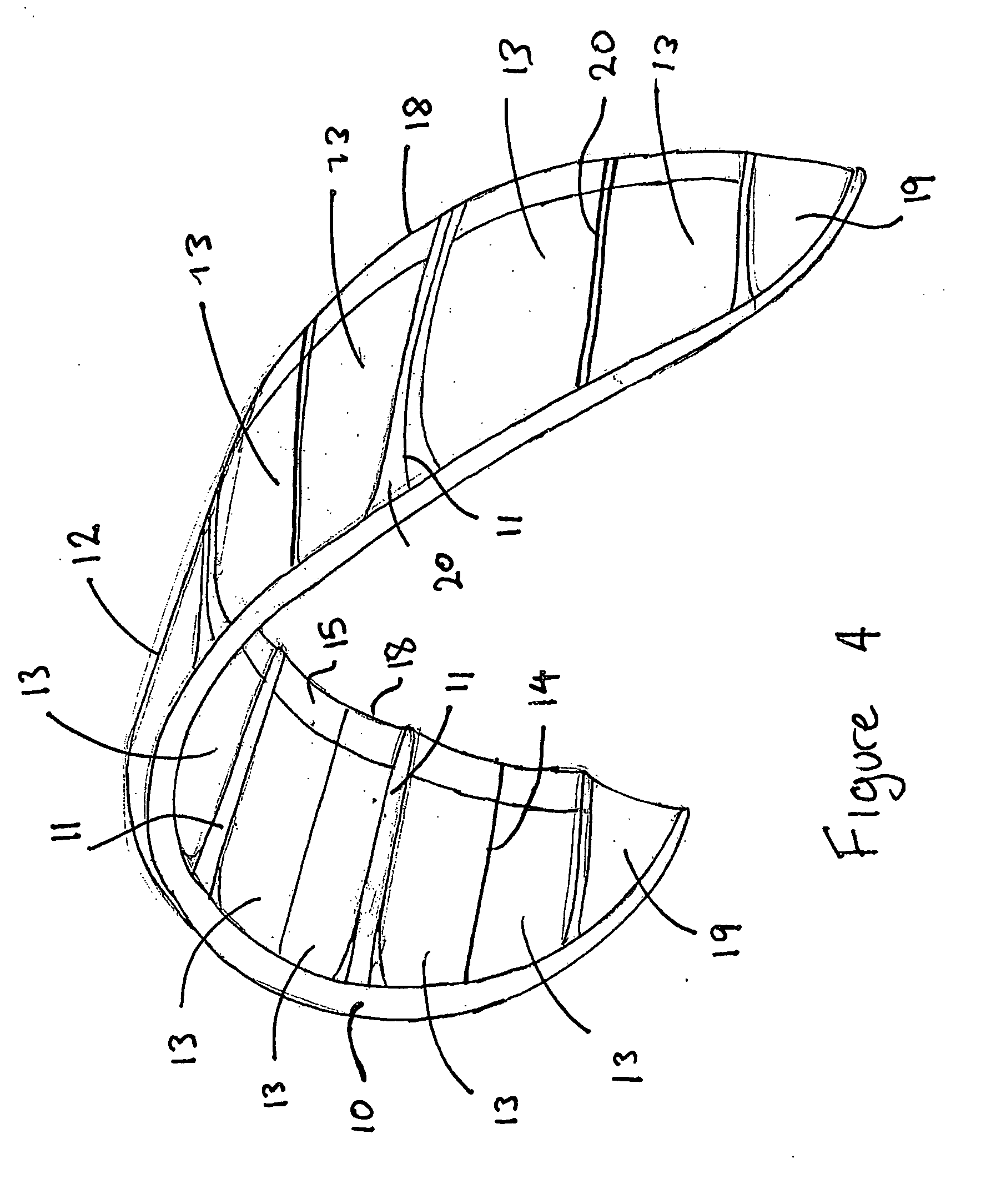

[0031]Referring to FIGS. 1 through 3, the laminated material comprises two outer layers 1, 2 of thin, non woven, flexible film sandwiching an inner layer 3 of stretch resistant reinforcing material. In the preferred embodiment the non woven flexible film is 0.02 millimetres thick aluminium coated Polyethylene Terephthalate (PET) film, and the reinforcing material comprises stretch resistant polyester yarn arranged in first and second groups of parallel strands 4, 5 with the strands in the first group crossing the strands in the second group at an angle of between 30 and 60 degrees. The layers 1, 2, 3 are laminated together in a typical laminating process using BOSTIK® solvent base polyester resin glue. The material is easily manufactured, low cost and has high strength and low elongation in all directions.

[0032]Although PET film is preferred because it is cheap, easily obtainable or manufactured, and has high tensile strength and dimensional stability for it relative thickness, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com