Determination of an actual optimum salinity and an actual optimum type of microemulsion for surfactant/polymer flooding

a technology of surfactant/polymer flooding and optimum type of microemulsion, which is applied in the direction of fluid removal, survey, borehole/well accessories, etc., can solve the problem of leaving behind a significant portion of the total amount of oil in the reservoir

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

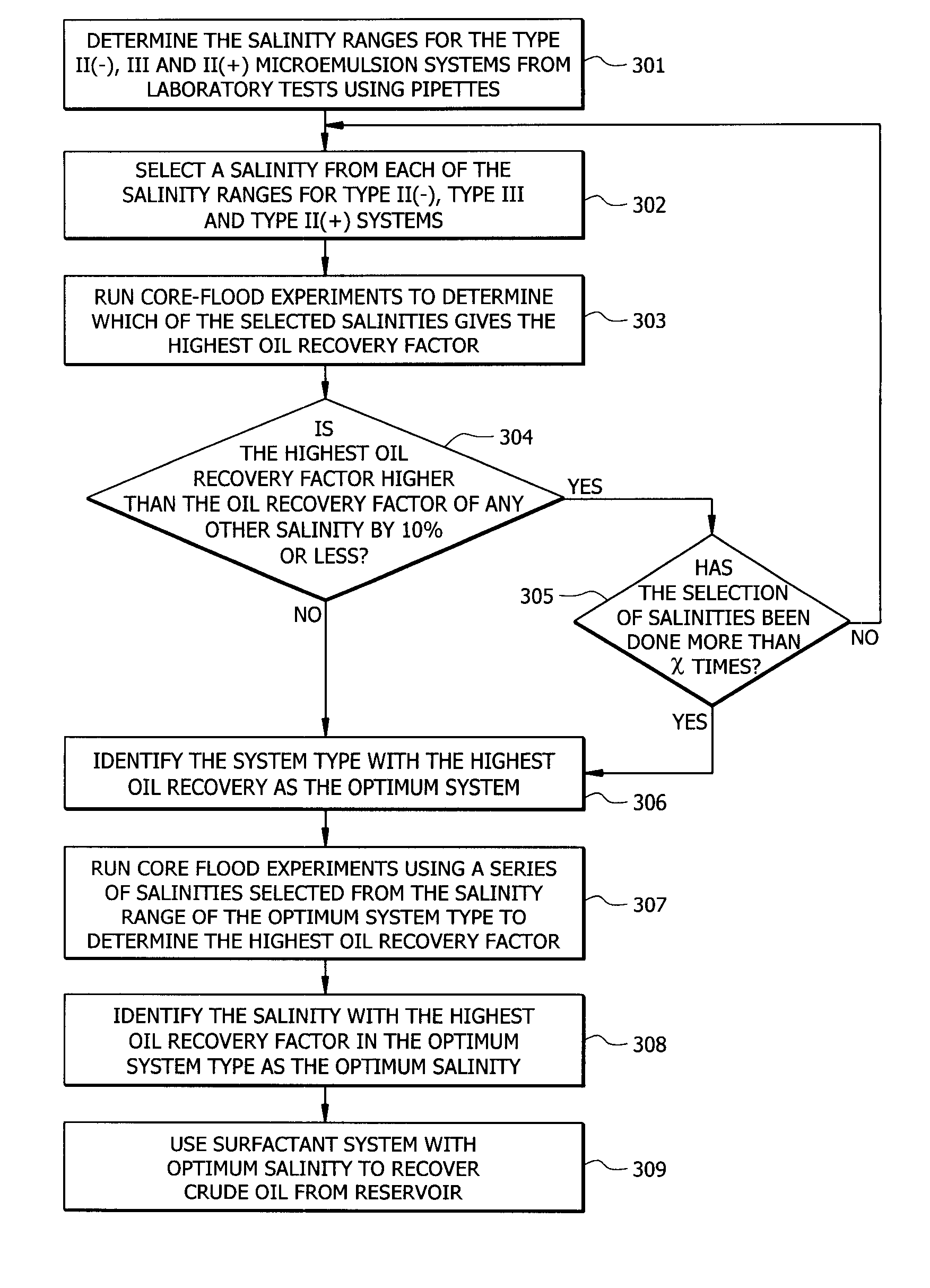

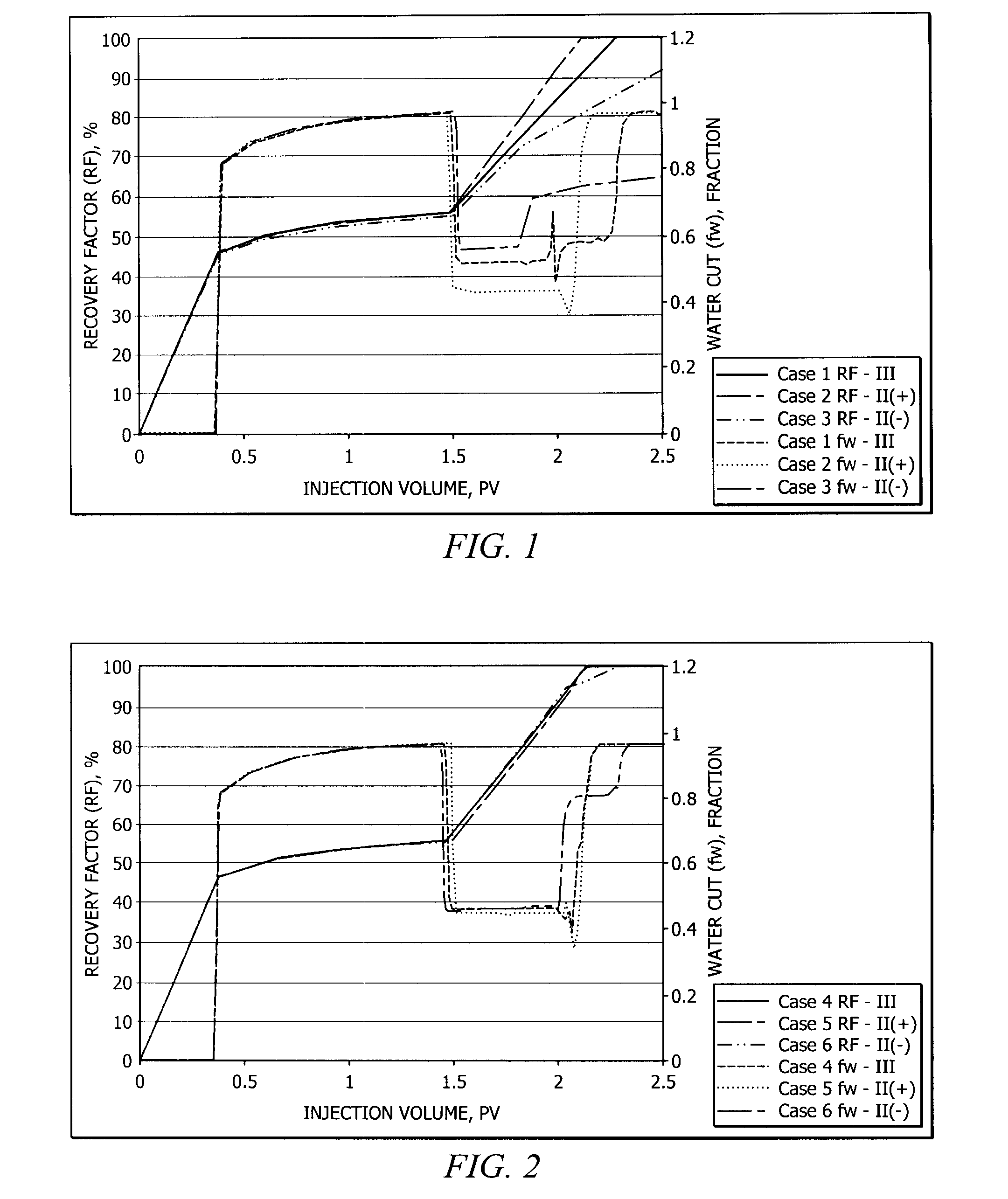

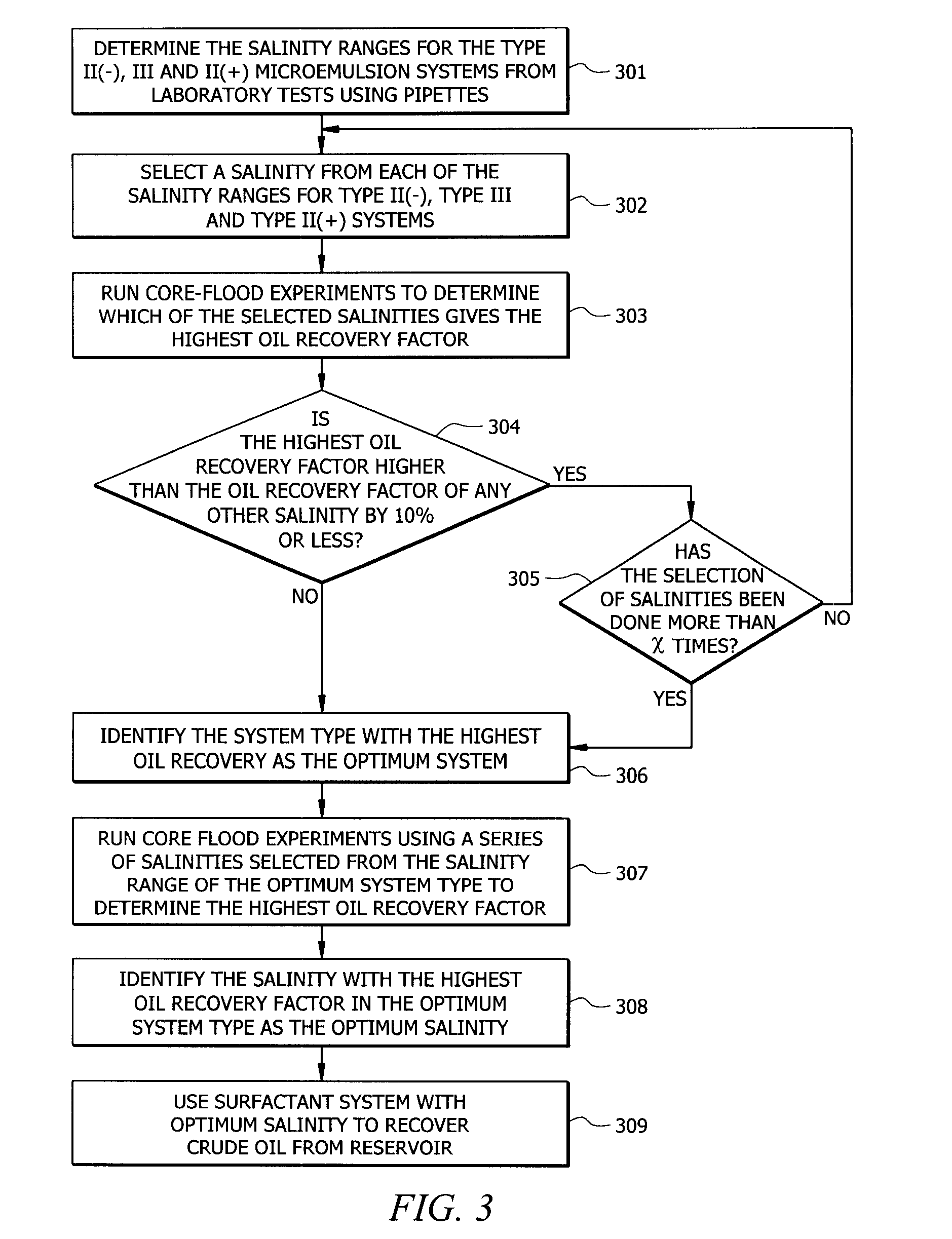

[0019]The current state of the art of determining an optimum salinity within a Type III microemulsion system focuses on one parameter-interfacial tension. In arriving at the present invention, though it was believed that interfacial tension is an important factor in the ultimate oil recovery, it was realized that other potentially important parameters were not being taken into account in the selection of the optimum salinity type. Accordingly, it was hypothesized that if the other parameters such as relative permeability, phase trapping and adsorption, were taken into account, the actual optimum salinity determined would, often times, be other than a Type III and / or a different value from the conventional optimum salinity. Simulations of multiphase flow in surfactant flooding were conducted to determine the effect of several parameters on oil recovery factor.

[0020]The simulations were conducted on a chemical flood simulator known as the University of Texas Chemical Simulator, UTCHEM...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com