Liquid tank structure of heat exchanger

a technology of liquid tank and heat exchanger, which is applied in the direction of subcoolers, refrigeration machines, lighting and heating apparatus, etc., can solve the problems of increasing the enclosed capacity of refrigerant and increasing the consumption amount of refrigerant, and achieve the effect of decreasing the necessary amount of refrigeran

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0047]Hereinafter, a liquid tank structure of a heat exchanger of a first embodiment according to the present invention will be described. Incidentally, the liquid tank structure of the heat exchanger of the first embodiment is applied to a liquid tank which is mounted on a motor vehicle. Herein, a condenser corresponds to the heat exchanger of the present invention.

[0048]First, an entire structure of the heat exchanger with the liquid tank structure of the first embodiment will be described.

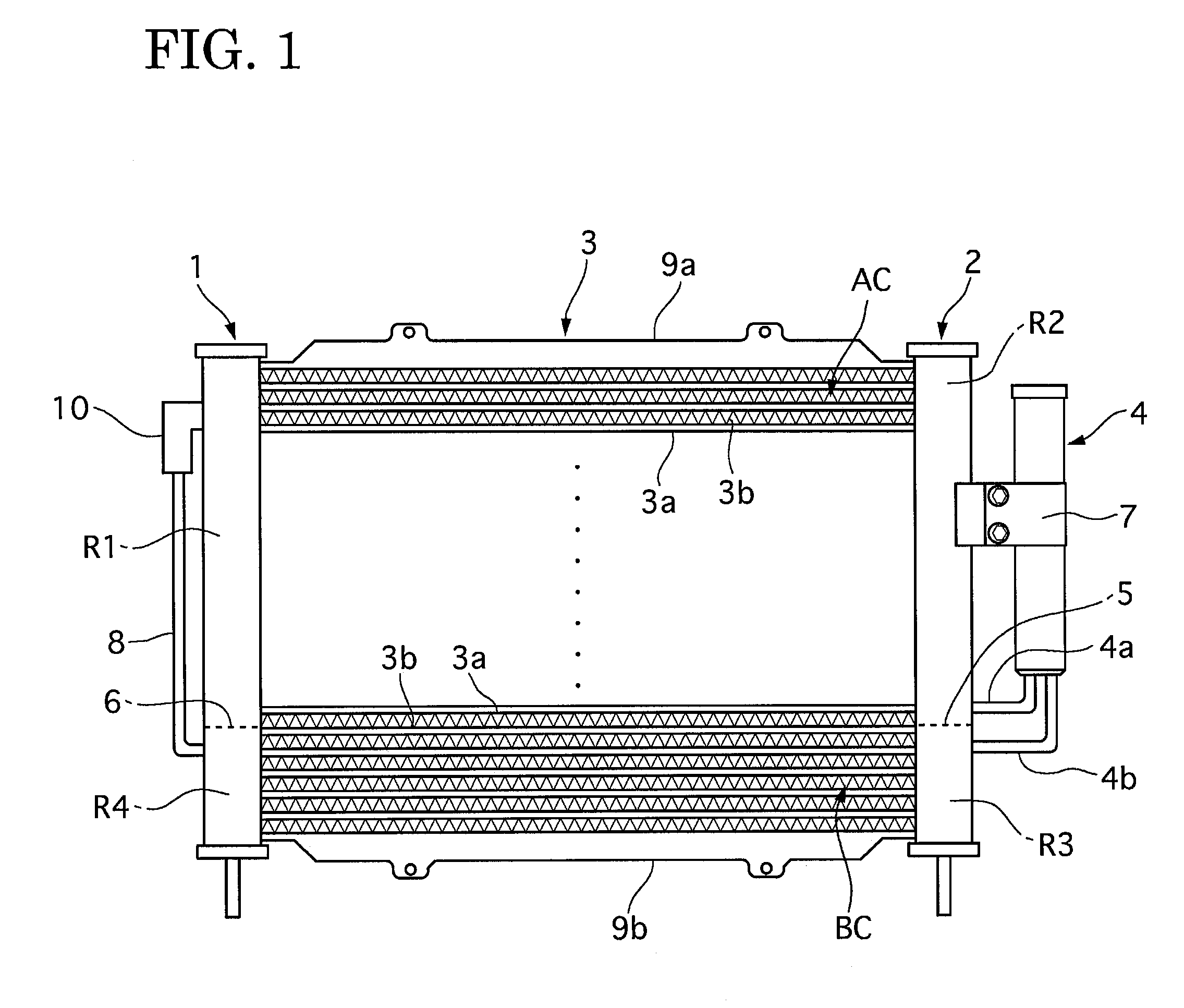

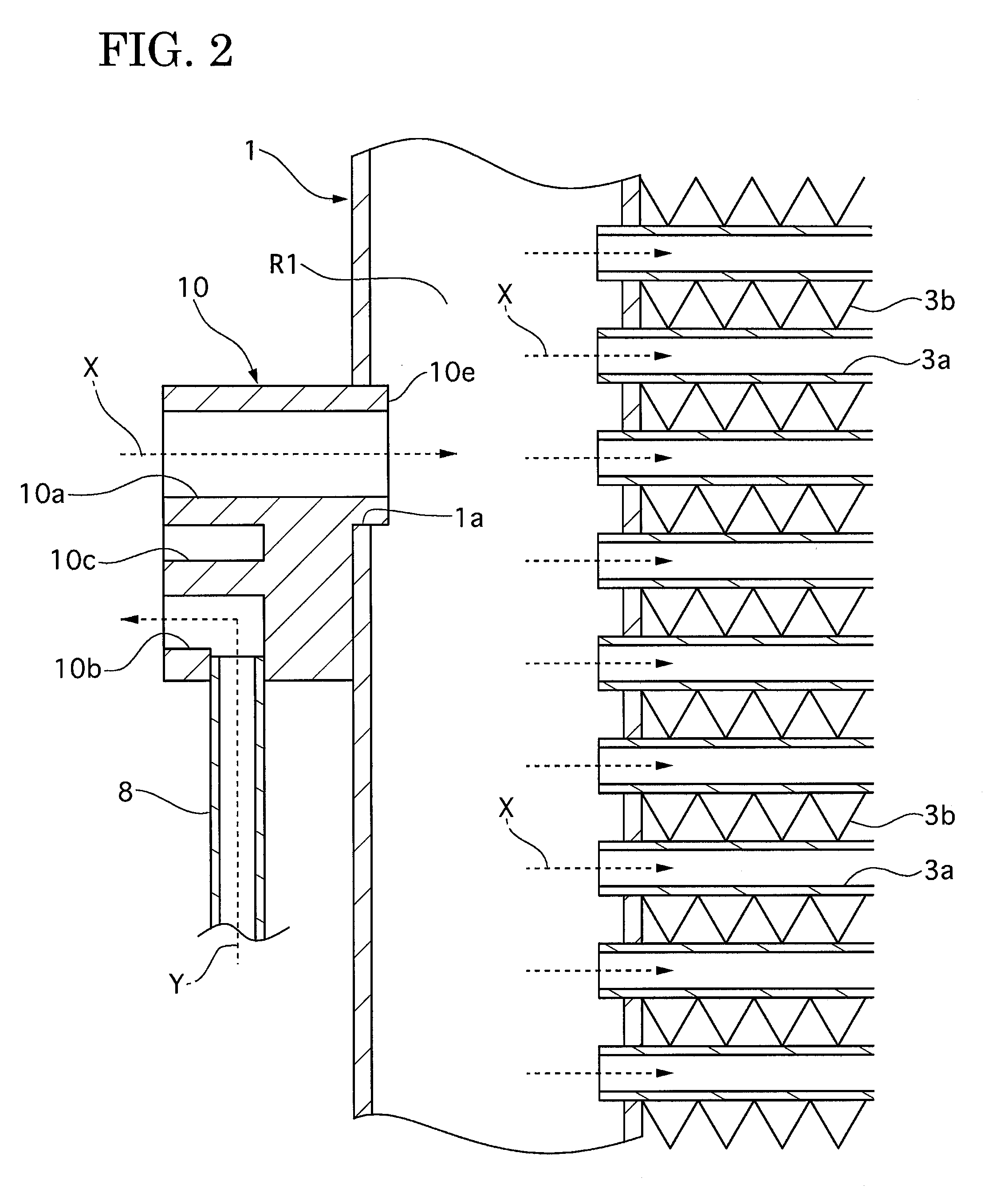

[0049]As shown in FIG. 1, the liquid tank structure of the heat exchanger of the first embodiment has a pair of headers 1 and 2, a condenser core 3 and a liquid tank 4.

[0050]The condenser core 3 is constructed by a plurality of tubes 3a and a plurality fins 3b, which are piled alternately to each other, and it is arranged between the pair of headers 1 and 2. The headers 1 and 2 are arranged at a right side and a left side, respectively, and their detail structure will later be described. Both en...

second embodiment

[0073]In a liquid tank structure of a heat exchanger of a second embodiment, as shown in an enlarged cross section view of a main part of a liquid tank of FIG. 6, the second embodiment is different from the first embodiment in that a sloshing suppression member 11 is arranged in a bottom portion of the liquid tank 4, and also in that the sloshing suppression member 11 is directly connected with an opening portion b1 formed on an end portion of an outlet-port side connecting pipe 4b. The other parts and portions of the second embodiment is constructed similarly to those of the first embodiment.

[0074]This means that, in the liquid tank structure of the second embodiment, falling condensed refrigerant passes through the sloshing suppression member 11, and then it is directly sent to an under cooling part BC through the outlet-port side connecting pipe 4b and the third room R3 of a header 2. Accordingly, the liquid tank structure of the second embodiment can obtain the effects similar t...

third embodiment

[0075]In a liquid tank structure of a third embodiment, it is different from the first and second embodiments in that a sloshing suppression member 11 is partially arranged in a state where the sloshing suppression member 11 covers an opening portion of an outlet-port side connecting pipe 4b while it does not cover all are of a bottom portion of a liquid tank. The other parts and portions of the third embodiment are constructed similarly to those of the first embodiment.

[0076]This means that, in the liquid tank structure of the third embodiment, falling condensed refrigerant passes through the sloshing suppression member 11, and then it is directly sent to an under cooling part BC through the outlet-port side connecting pipe 4b and the third room R3 of a header 2. Accordingly, the liquid tank structure of the third embodiment can also obtain the effects similar to those of the second embodiment.

Fourth Enbodiment

[0077]In the above-described liquid tank structures of the first to thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com