Method of prevention of hydrates

a technology of hydrates and hydrates, applied in the direction of insulation, mechanical equipment, borehole/well accessories, etc., can solve the problems of increasing the number of hydrates in the pipeline, and substantial additional cooling, so as to prevent the formation of hydrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

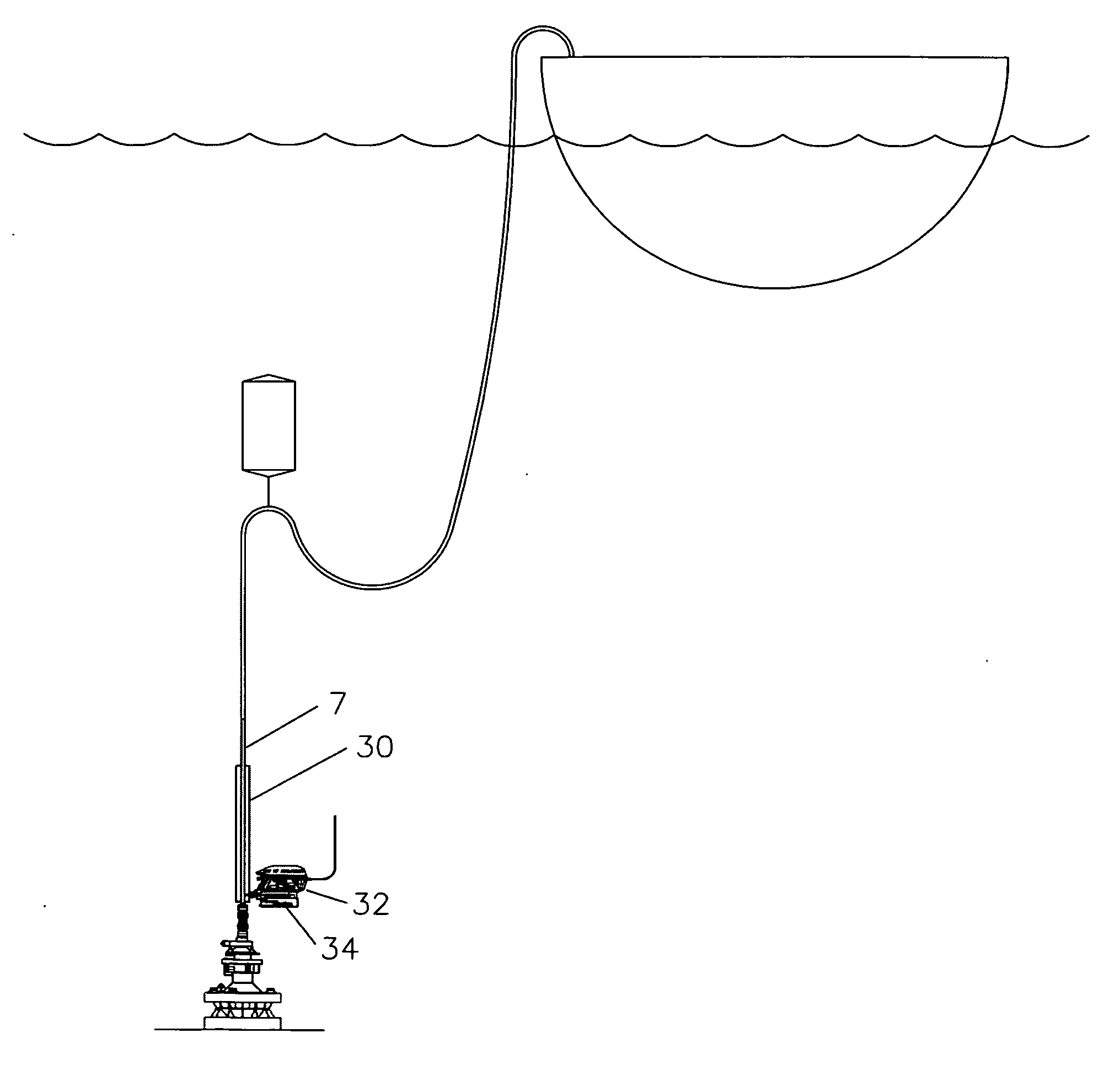

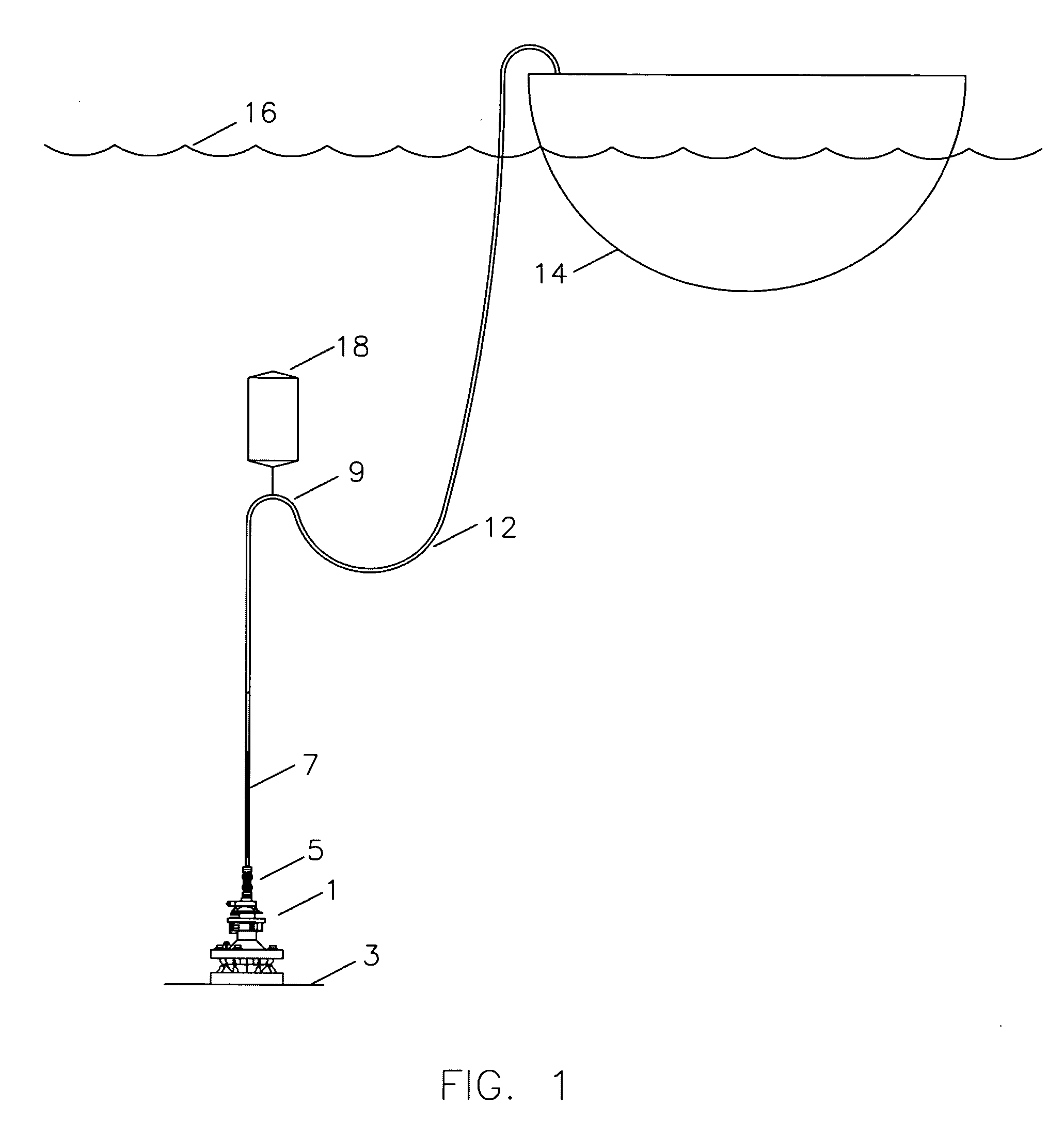

[0016]FIG. 1 shows a subsea installation 1, landed on the seafloor 3, a valve 5 to be opened, a riser pipe 7, a gooseneck 9, a flexible pipe 12, a surface vessel 14, at the ocean's surface 16, and a buoyant tank 18 to support the riser pipe 7.

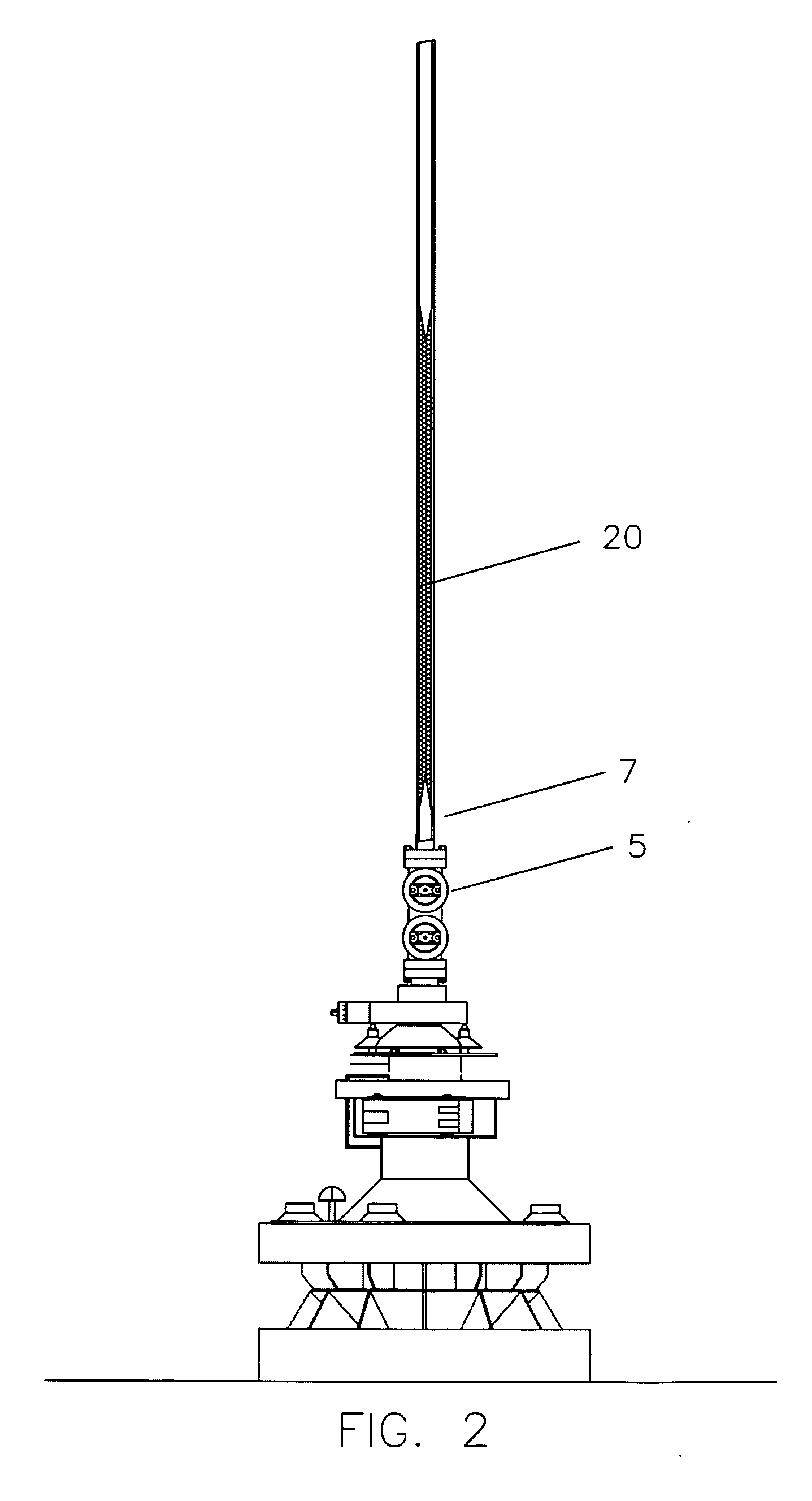

[0017]Referring now to FIG. 2, valve 5 has been closed for an extended period of time sufficient for all equipment and liquids to have been cooled to the temperature of the sea water, presumably 34° F. Valve 5 was opened and the cooled high pressure gas throttled across the opening valve into the lower pressure area in the riser pipe 7 above the valve. The blast of gas (probably methane) with a water content literally begins to freeze into a hydrate ice on the internal walls of the riser pipe 7 to the point of complete blockage as indicates as 20. At this time the operation has been required to wait until the hydrate melted of its own accord, in temperatures as low as 34° F.

[0018]Referring again to FIG. 1, access to the hydrate for mechanical r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com