Method and apparatus for improving distribution of fluid in a heat exchanger

a heat exchanger and fluid distribution technology, applied in indirect heat exchangers, lighting and heating apparatus, refrigeration components, etc., can solve problems such as significant reduction in heat exchanger efficiency and two-phase maldistribution, and achieve the effect of reducing the internal volume of a manifold and reducing the maldistribution of fluid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

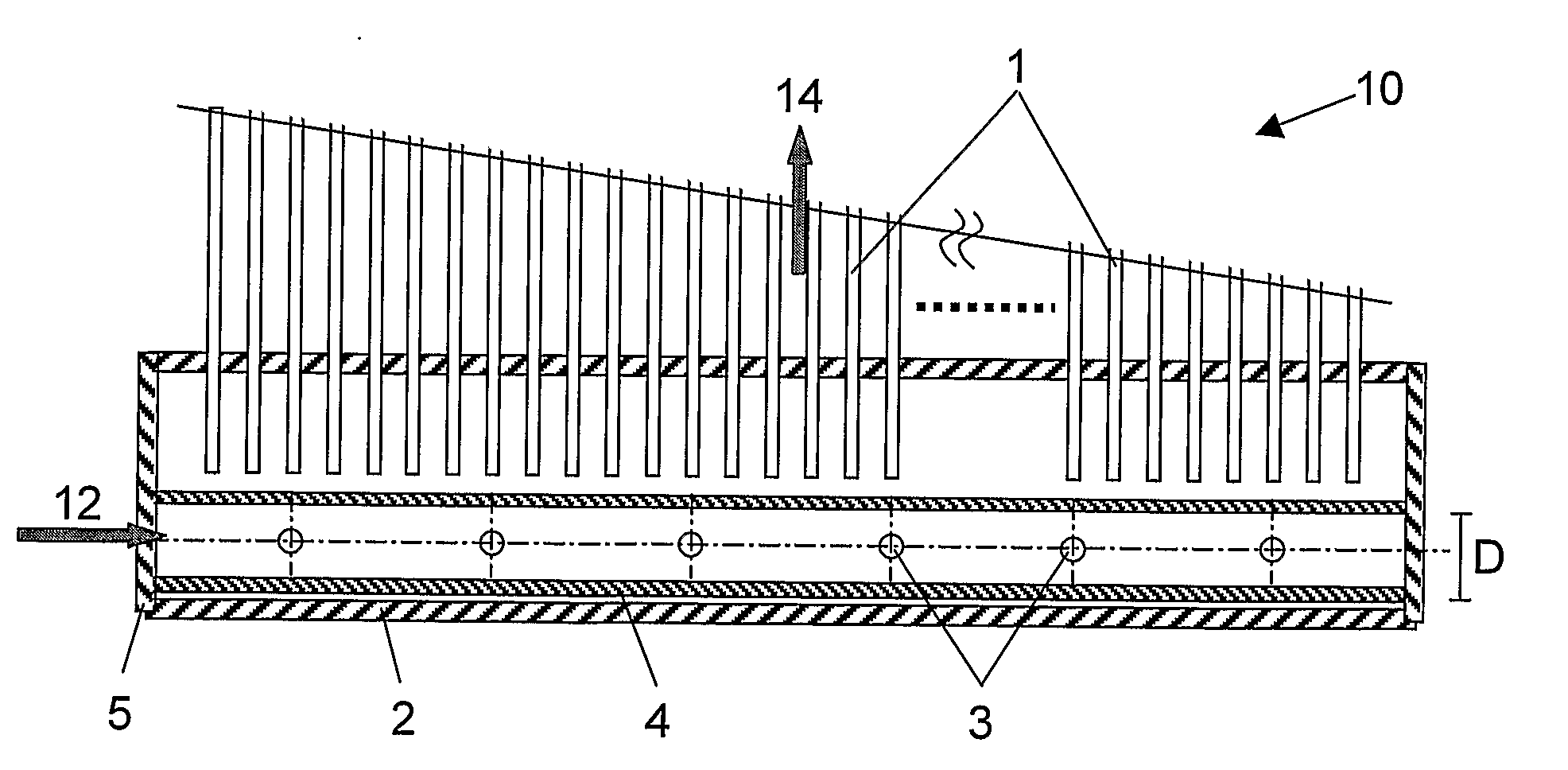

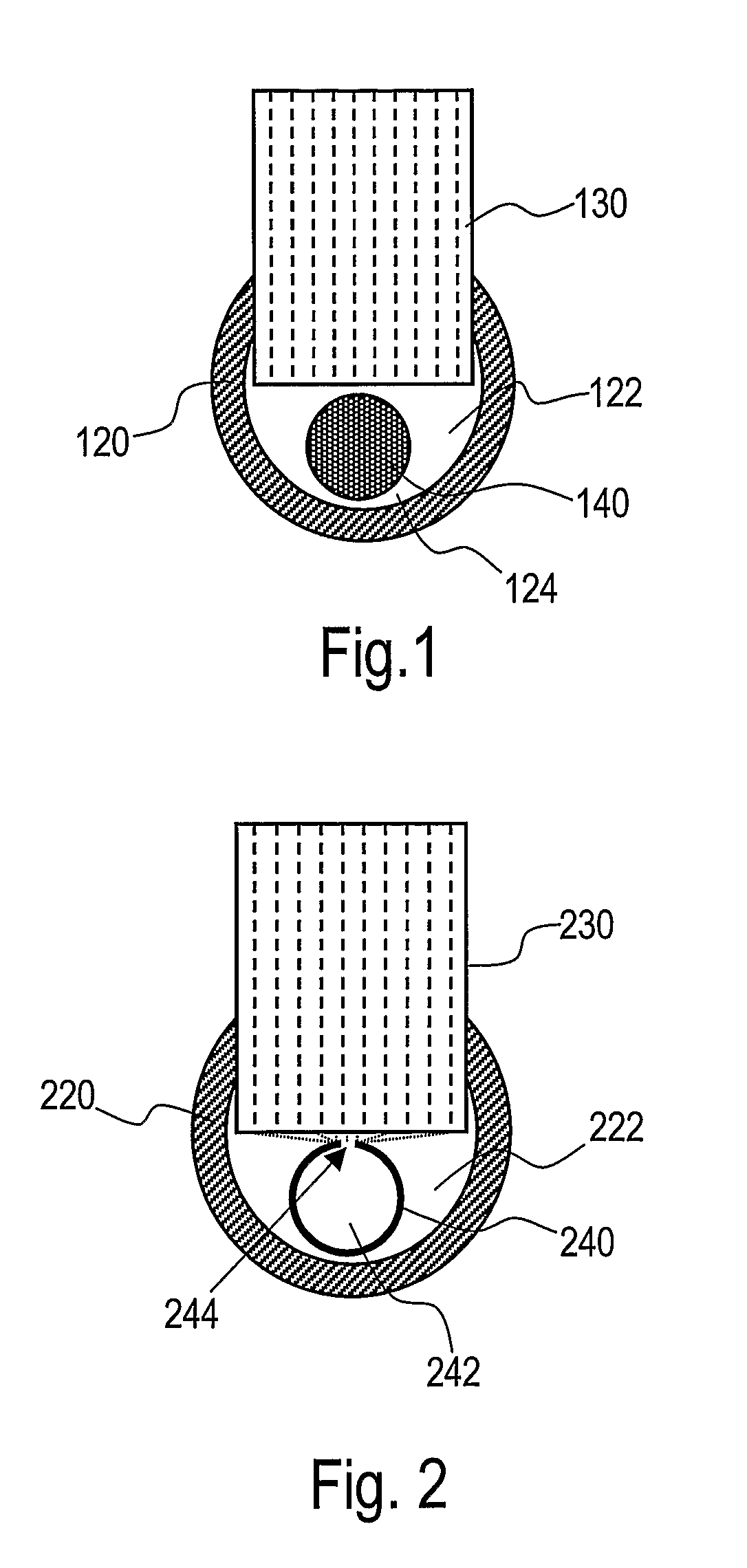

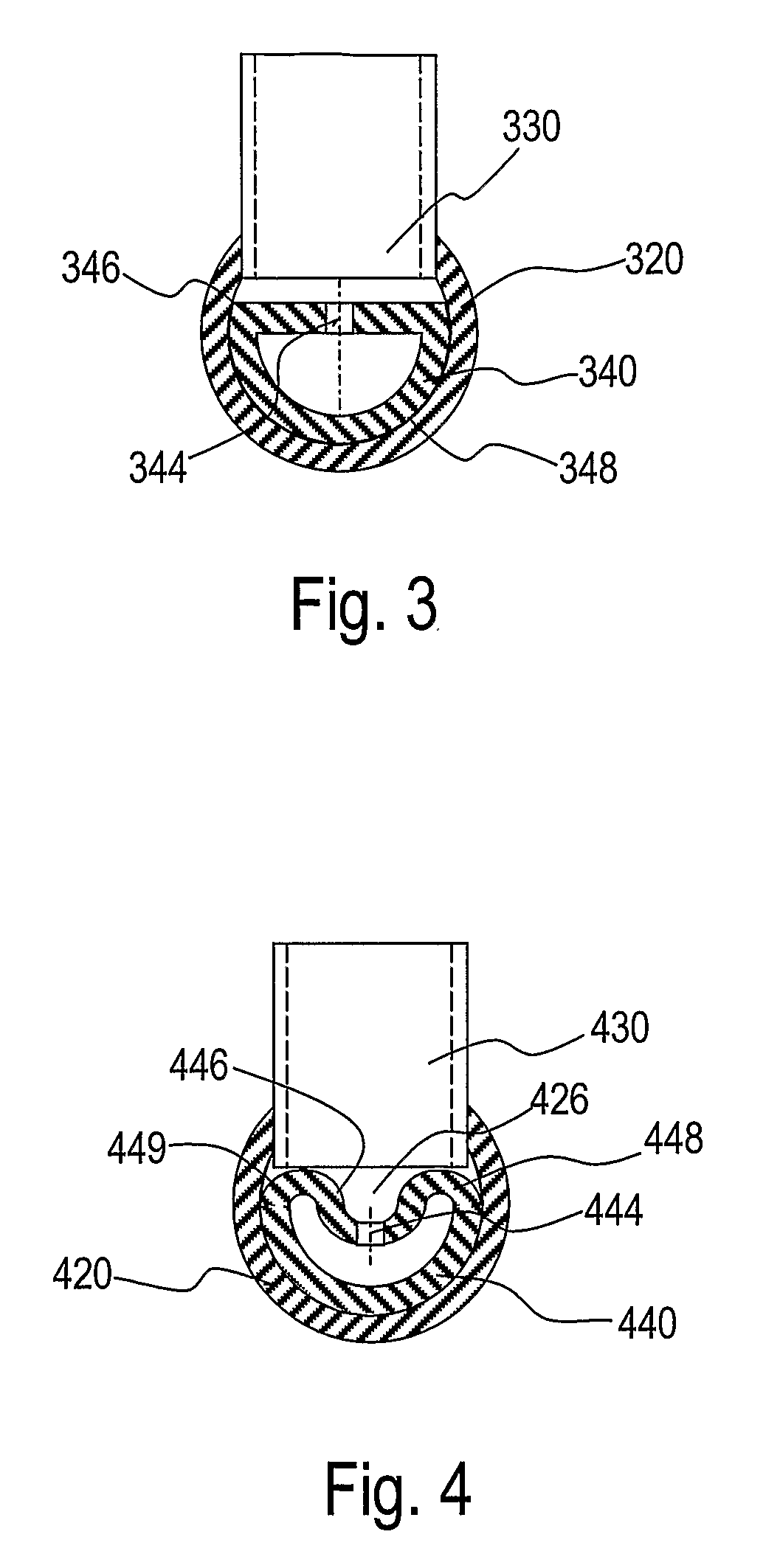

[0023]It has been determined by the present disclosure that maldistribution in a MCHX heat exchanger, e.g., evaporator, condenser, gas cooler, or any other heat exchanger, may be reduced by reducing an internal volume of a manifold or header that distributes a multiple-phase flow, for example, a two-phase flow including both a vapor and a liquid, to parallel refrigerant paths, for example, tubes. Without wishing to be bound by any particular theory, it is believed that by reducing the total internal volume of the manifold, the velocity and mass flux of a two-phase fluid can be increased promoting internal mixing and also a volume over which a gas phase and a liquid phase of the two-phase flow separates is reduced as a result of these factors a relatively uniform and homogeneous mixture of vapor and liquid can be distributed to tubes that are parallel. Advantageously, it has been determined that an insert or shape of the manifold reduces the internal volume of the manifold. The inser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com