Improved recloseable package for pinch-grip opening

a technology of recloseable fasteners and opening packages, which is applied in the field of packages, can solve the problems of shortening the shelf life of packaged products, compromising the gas barrier properties of packages, and patents that do not recognize the mechanics involved in pinch-grip opened packages with certain types of recloseable fastener assemblies, so as to facilitate the initial separation of the first and second fastener elements, and facilitate the securement of the inside surfa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]While the present invention is susceptible of embodiment in various forms, there is shown in the drawings and will hereinafter be described a presently preferred embodiment of the invention, with the understanding that the present disclosure is to be considered as an exemplification of the invention, and is not intended to limit the invention to the specific embodiments illustrated.

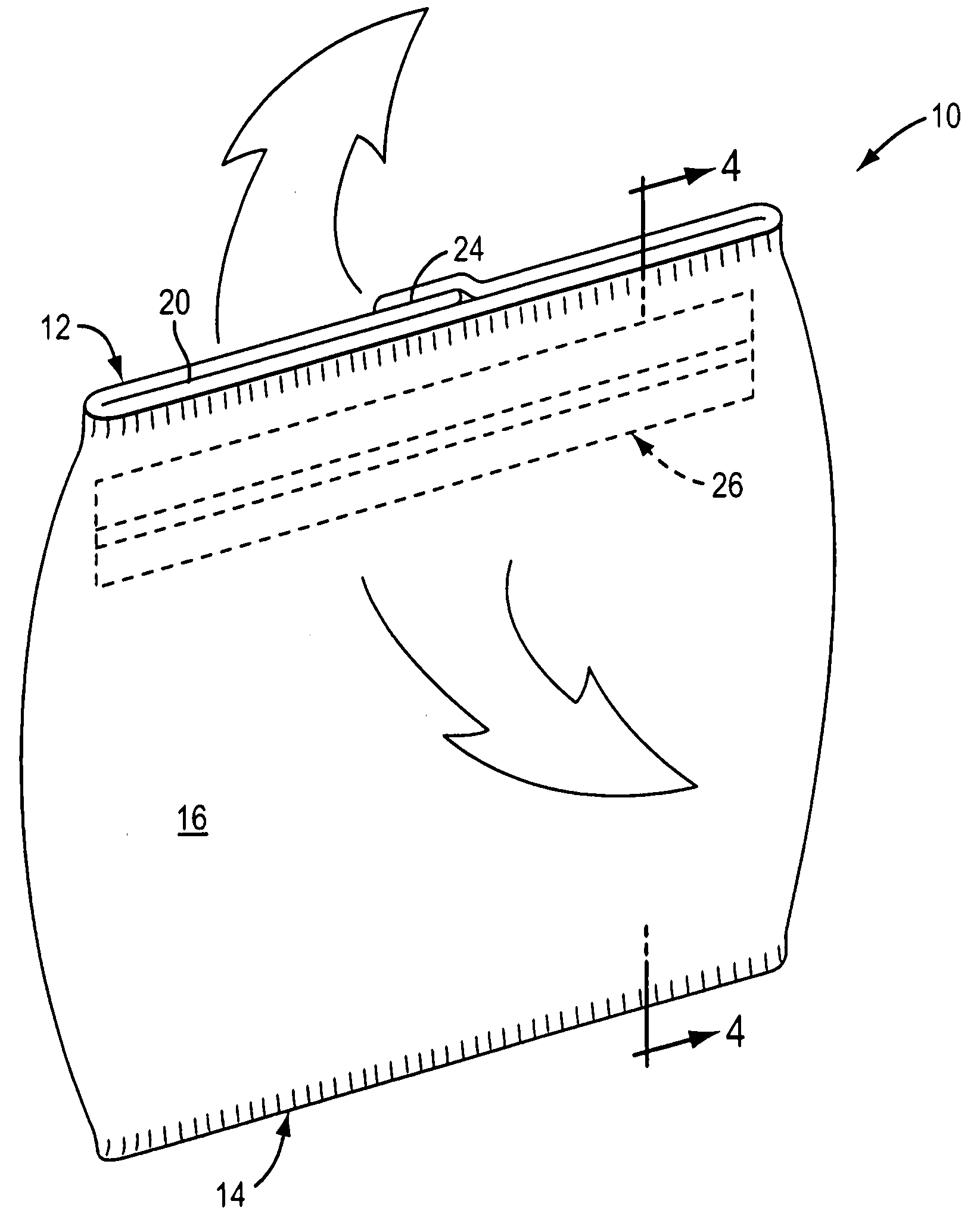

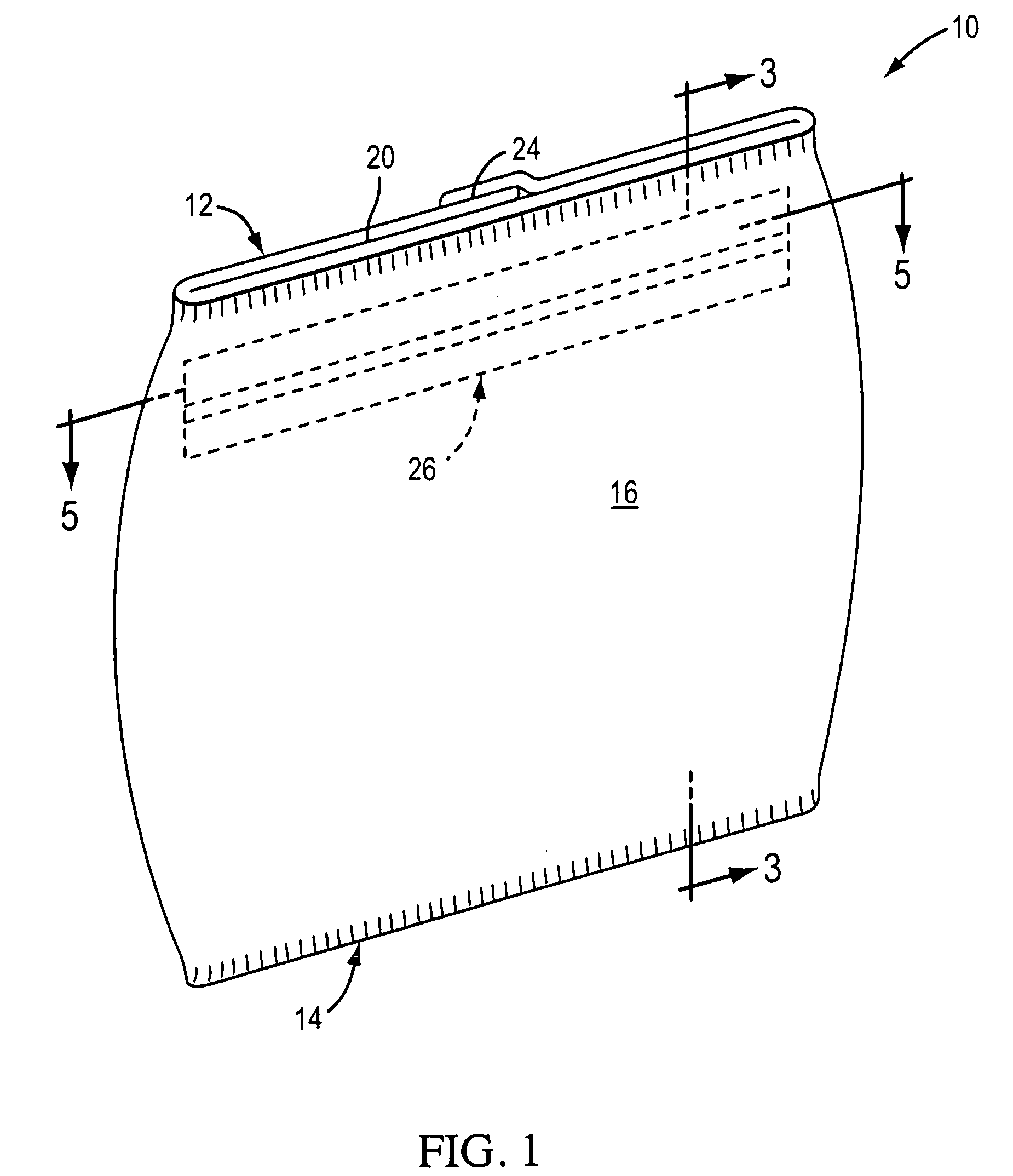

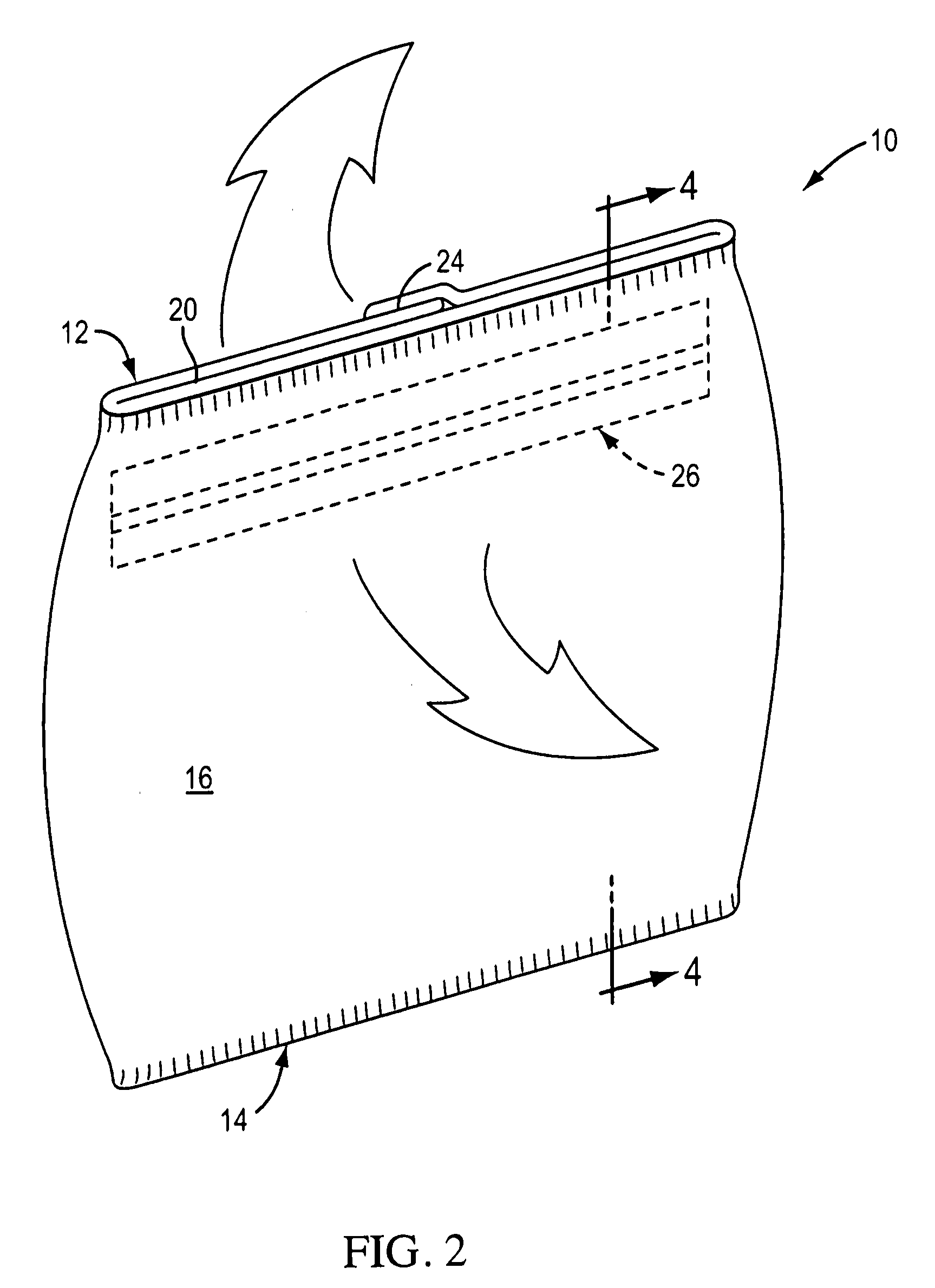

[0032]With reference now to the drawings, therein is illustrated a package in the form of a recloseable bag 10 embodying the principles of the present invention. It is contemplated that the bag 10 be formed from suitable plastic film materials or the like, but it is within the purview of the present invention to form the bag from paper or paper-like materials. As will hereinafter be described, bag 10 is specifically configured in a manner which facilitates formation of the bag from a substantially continuous web of film material, to which fastener assemblies have been previously applied, for use in ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap