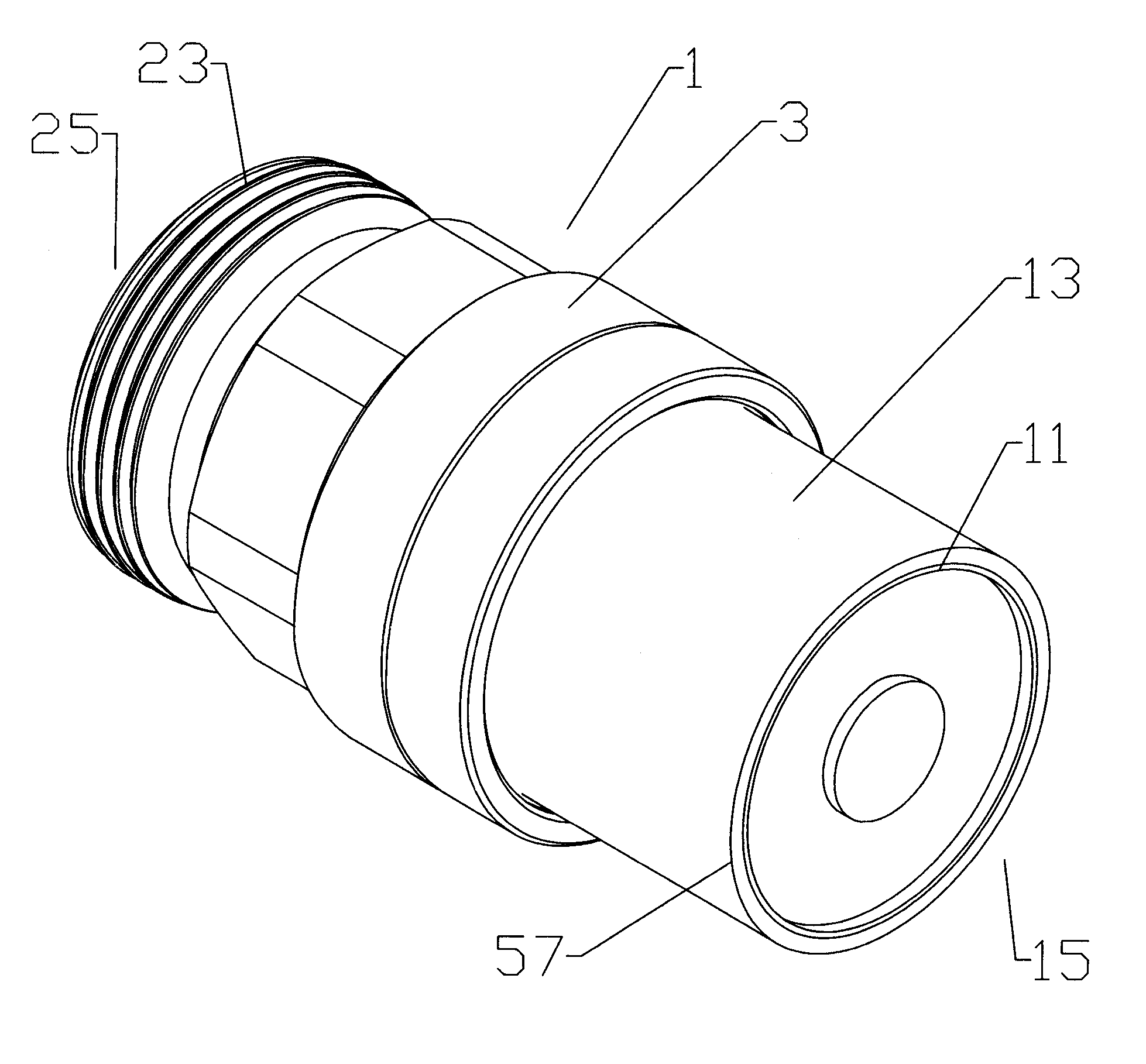

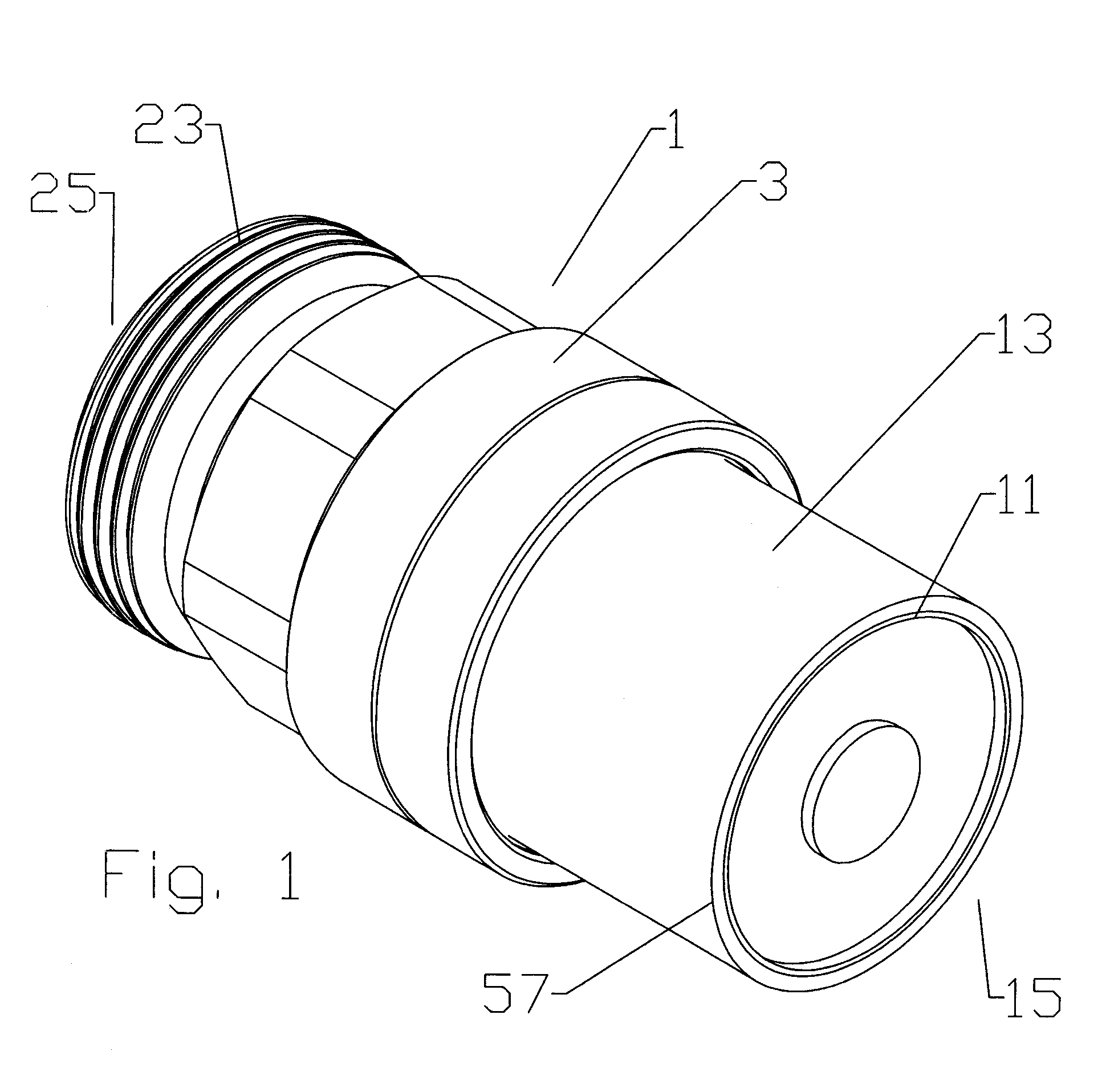

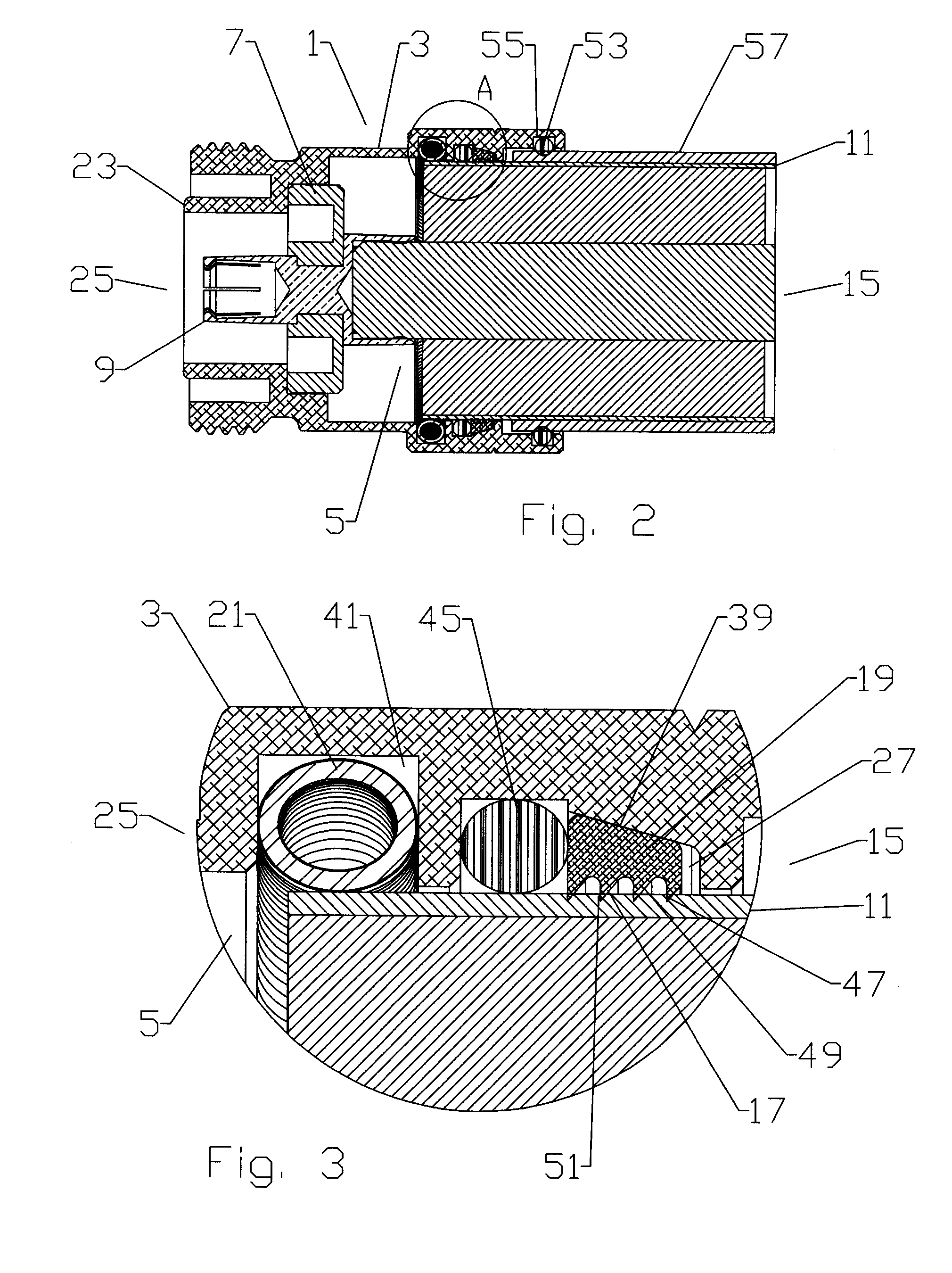

Shielded grip ring for coaxial connector

a technology of shielding grip and coaxial cable, which is applied in the direction of coupling device connection, two-part coupling device, electrical apparatus, etc., can solve the problems of increasing manufacturing cost and installation time requirements, and crimping and/or compression becomes impractical with larger diameter coaxial cabl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

The inventor analyzed available solid outer conductor coaxial connectors and recognized the drawbacks of threaded inter-body connection(s), manual flaring installation procedures and crimp / compression coaxial connector designs. Insertion coupling coaxial connectors, for example as disclosed in the inventor's commonly owned U.S. Utility patent application Ser. No. 12 / 264,932, titled “Insertion Coupling Coaxial Connector”, filed Nov. 5, 2008, currently pending and hereby incorporated by reference in its entirety, introduces several significant improvements to the coaxial connector arts, eliminating the need for manual flaring of the outer conductor and / or high torque threading of the coupling nut into the connector body during outer conductor end clamping connector to cable end interconnection. Similarly, several improvements to the insertion coupling coaxial connector are disclosed in the inventors commonly owned U.S. Utility patent application Ser. No. 12 / 611,095, titled “Insertion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com