Integral insole with multiple areas of different resiliency and method of making the insole

a technology of insoles and resiliency, applied in the field of insoles, can solve the problems of eva foam lack of durability and breakage with each step, and achieve the effect of providing resiliency and comfor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

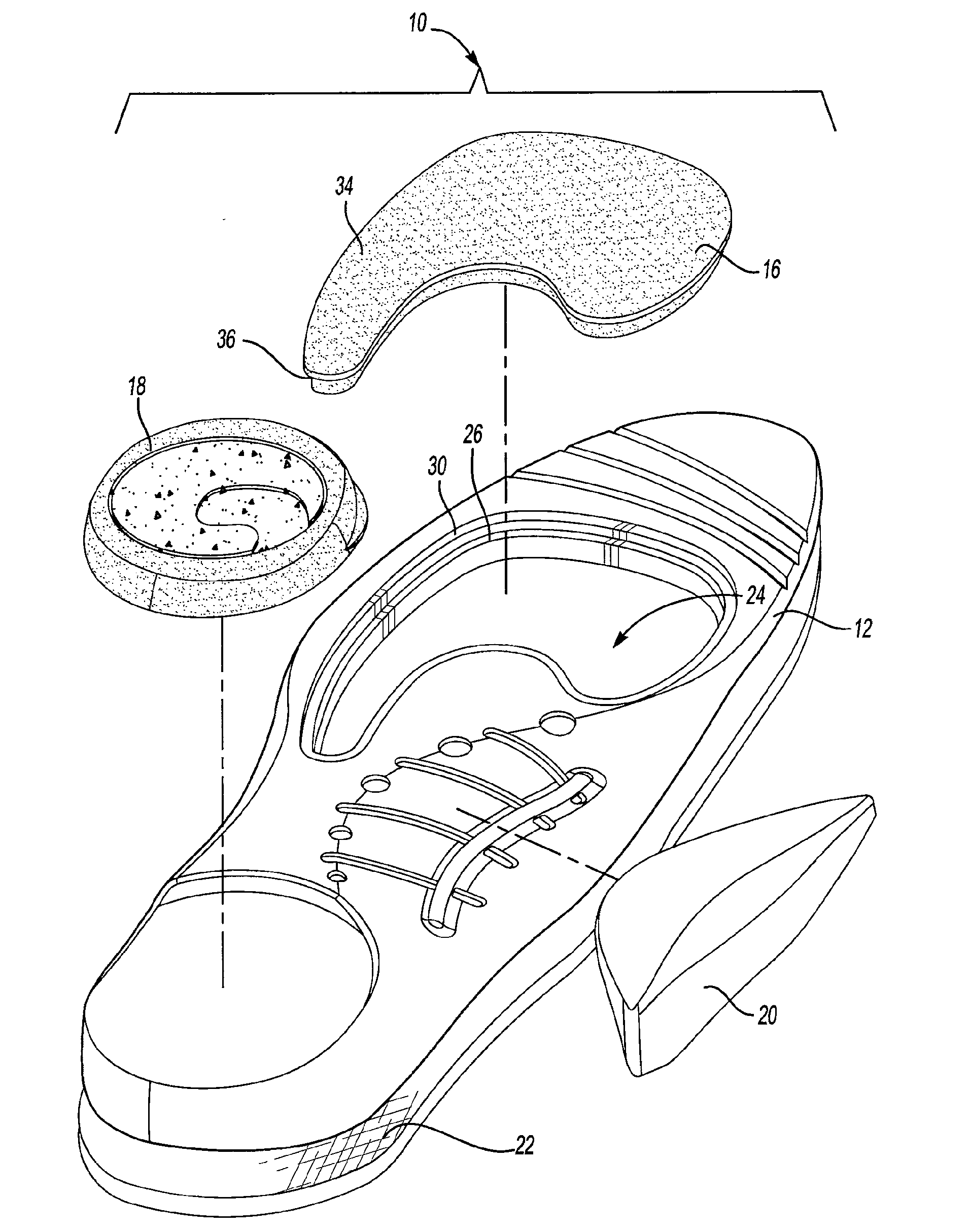

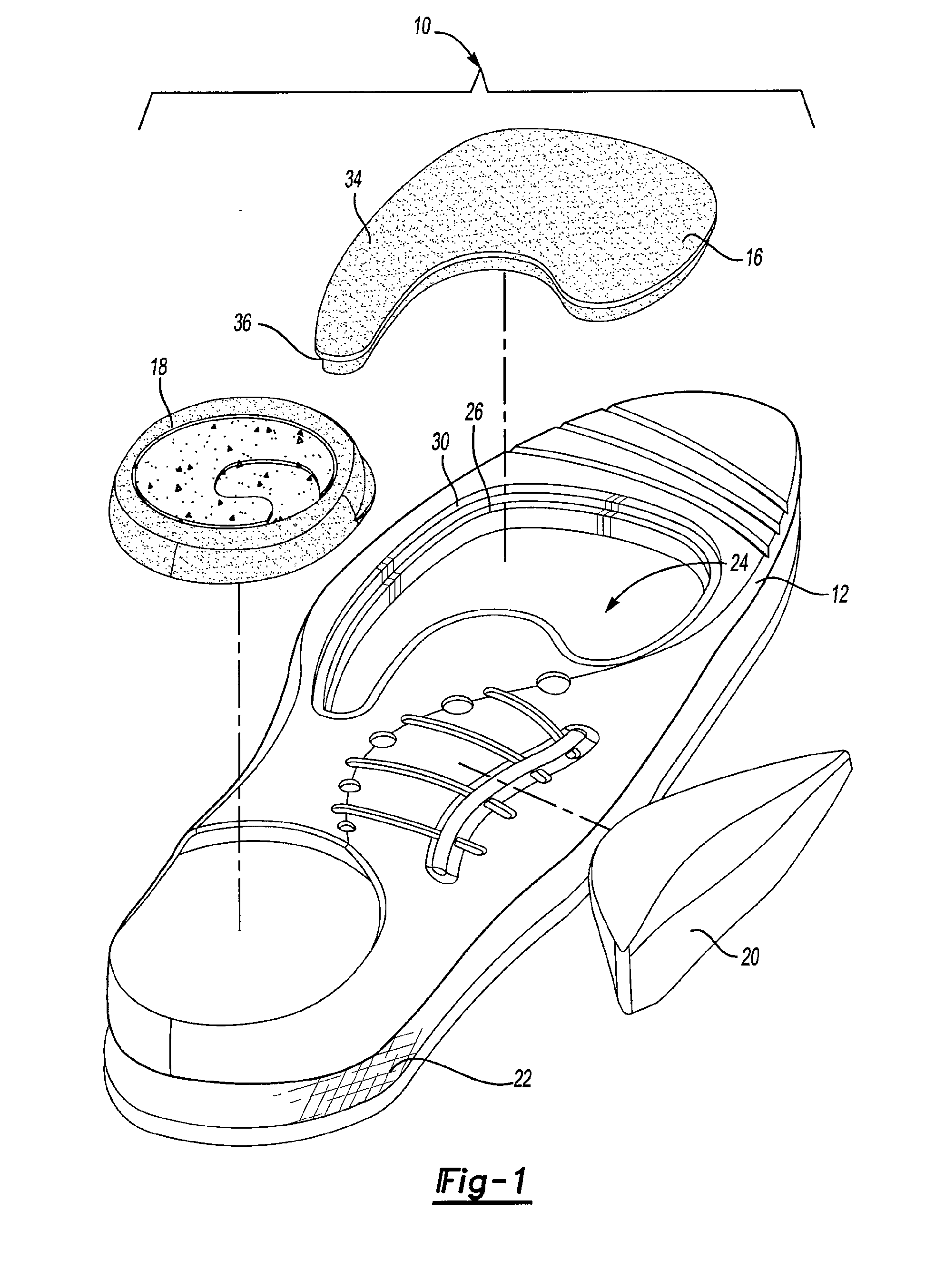

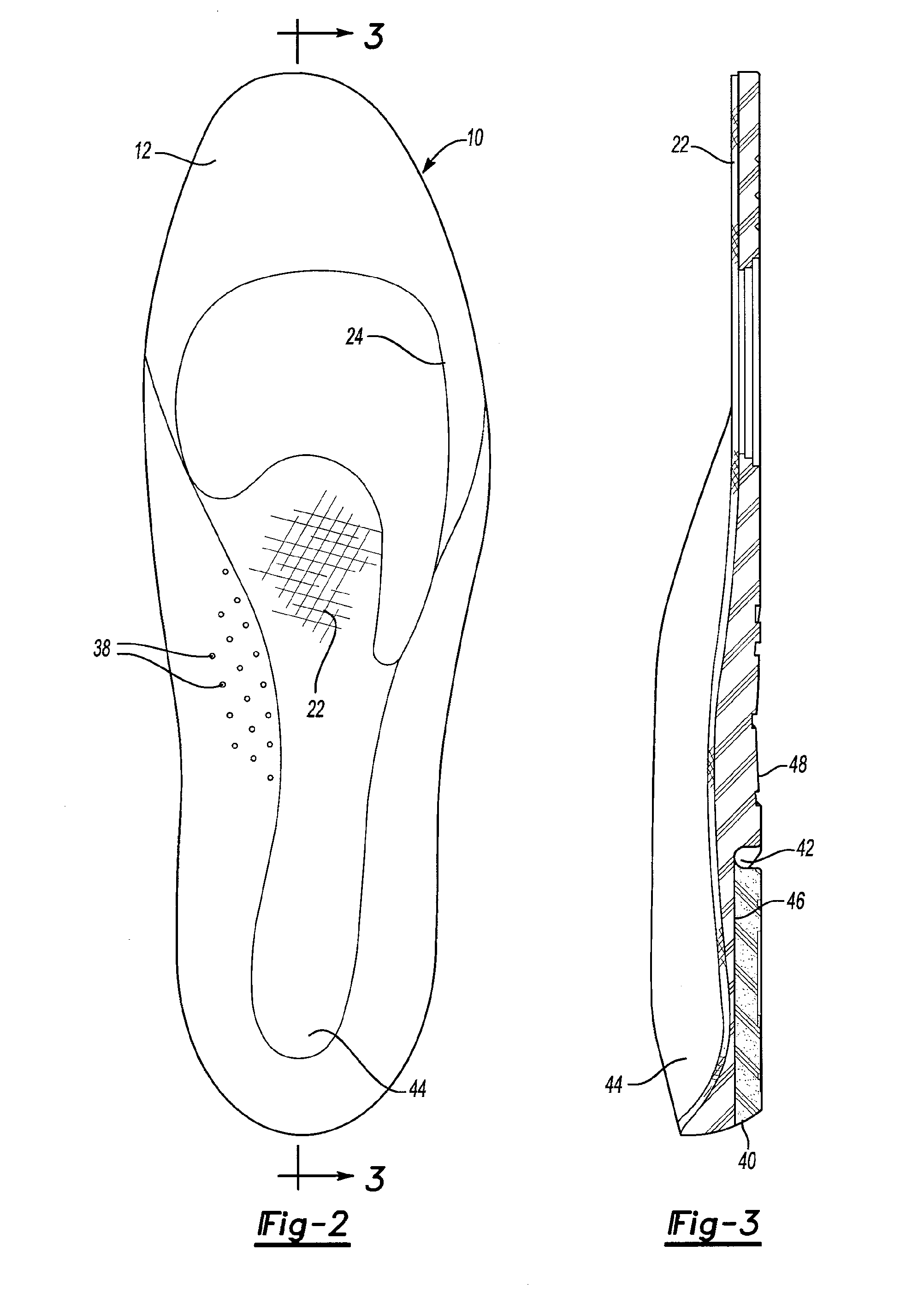

[0030]Referring to FIG. 1, a insole 10 is illustrated with its component parts separated from the insole 10. Insole 10 includes a body portion 12 that is formed of a mixture of polyurethane and granulated cork particles. It should be understood that the body portion may be formed from another mixture of material that offers similar resiliency and strength characteristics. The body portion 12 in the illustrated exemplary embodiment is made from a polyurethane foam or elastomer having a hardness in the range of 20 to 50 on the Shore A scale. More specifically, the hardness range may be between 25 and 36 on the Shore A scale with the optimum hardness believed to be about 30 on the Shore A scale. The polyurethane foam is a two-part polyurethane including polyol and isocyanate and a blowing agent that are blended with granulated cork particles that increase the hardness of the mixture after curing. The granulated cork particles are preferably 14 / 30 mesh granulated cork. The hardness of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com