Spout for a pouch

a technology for spouts and pouches, which is applied in the field of spouts for pouches, can solve the problems of contents leaking or deteriorating, possibly becoming so dirty, endangering health, etc., and achieves the effect of preventing a person from being damaged and maintaining sealing performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043]Reference will now be made in greater detail to a preferred embodiment of the invention, an example of which is illustrated in the accompanying drawings. Wherever possible, the same reference numerals will be used throughout the drawings and the description to refer to the same or like parts.

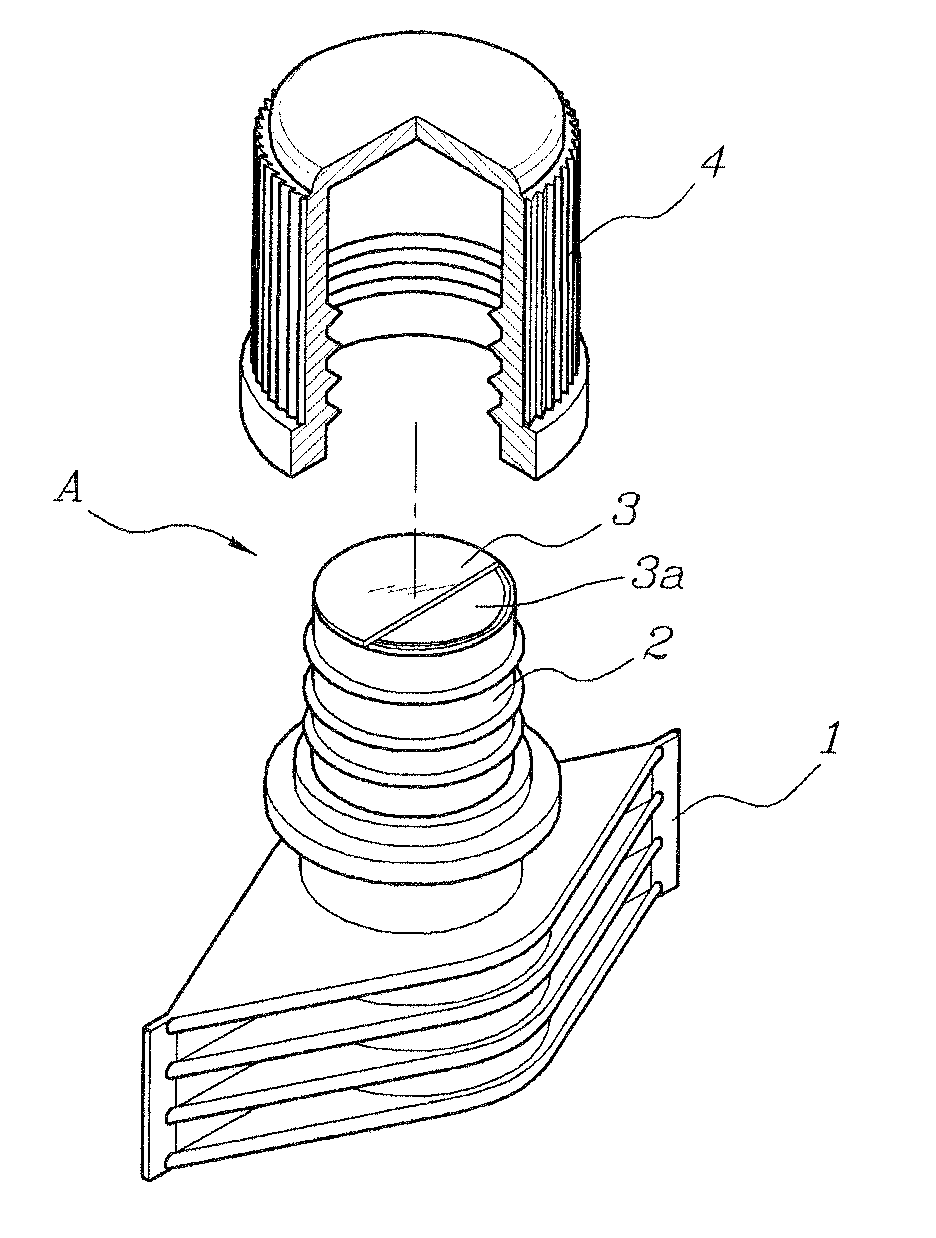

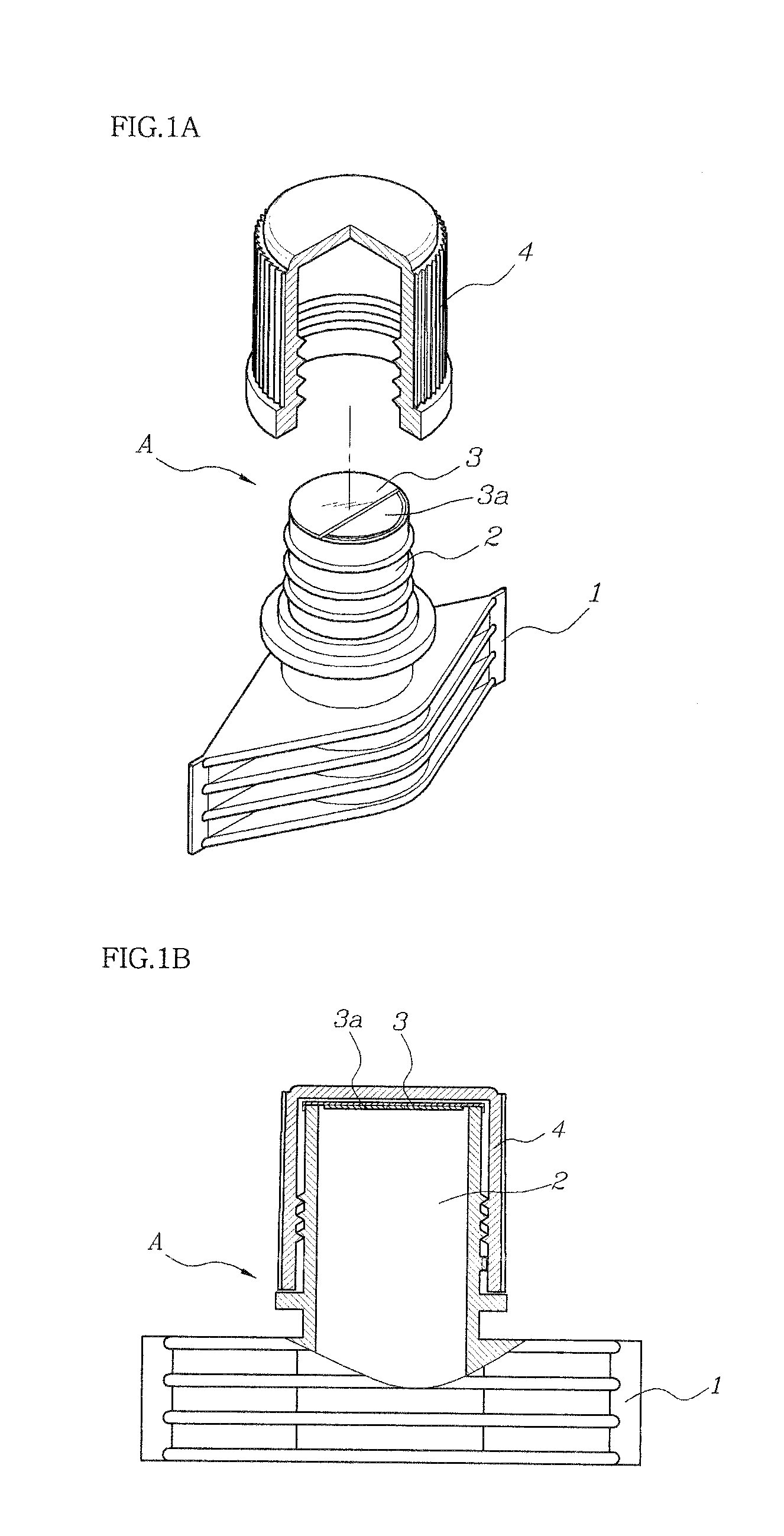

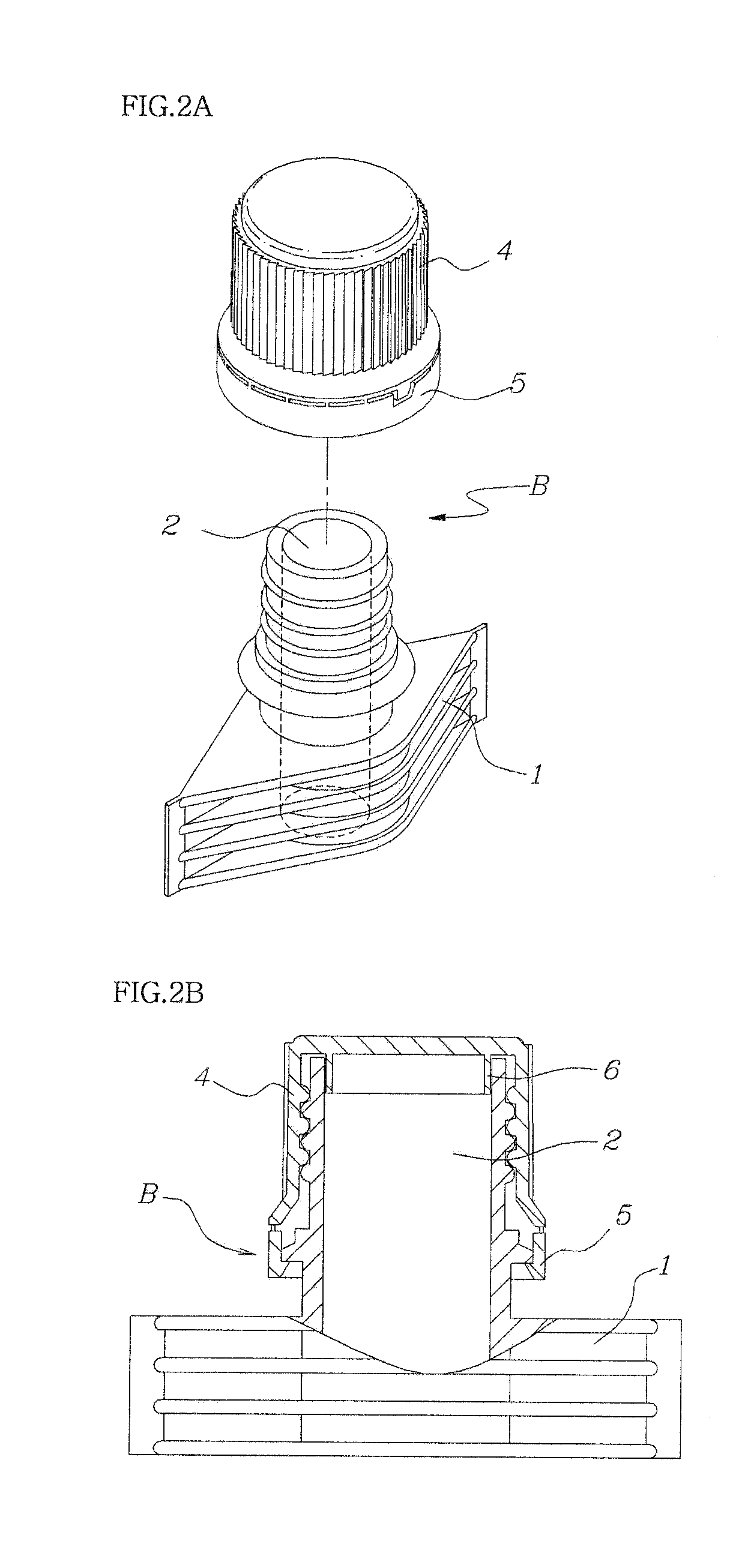

[0044]FIGS. 3 to 13 illustrate the structure of a spout for a pouch according to the present invention.

[0045]As illustrated in the drawings, the spout includes a body 10 which is bonded to a pouch 50, in which in general contents are filled, using e.g. a fusing method, and having an outlet 12 through which the contents are discharged from the pouch, a sealing end tube 30 which is integrally formed with the outlet via a thin and breakable sheet portion 32 so as to block the outlet, and a cap 20 which is spirally coupled with the body 10 so as to cover and protect the sealing end tube 30.

[0046]The cap 20 is made to be screw-coupled or spirally-coupled with the body 10, so that the cap and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| circumference | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com