Highway device, in particular manhole, with frame and plug with backward movement relative to the frame to ensure the closed position of the plug in the frame

a technology of manholes and frames, applied in the field of manholes, can solve the problems of affecting the sealing position the difficulty of maneuvering of the plug, and the heavy weight of the manhole cover plug, and risking damage to the edge of the plug and the corresponding end wall of the fram

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

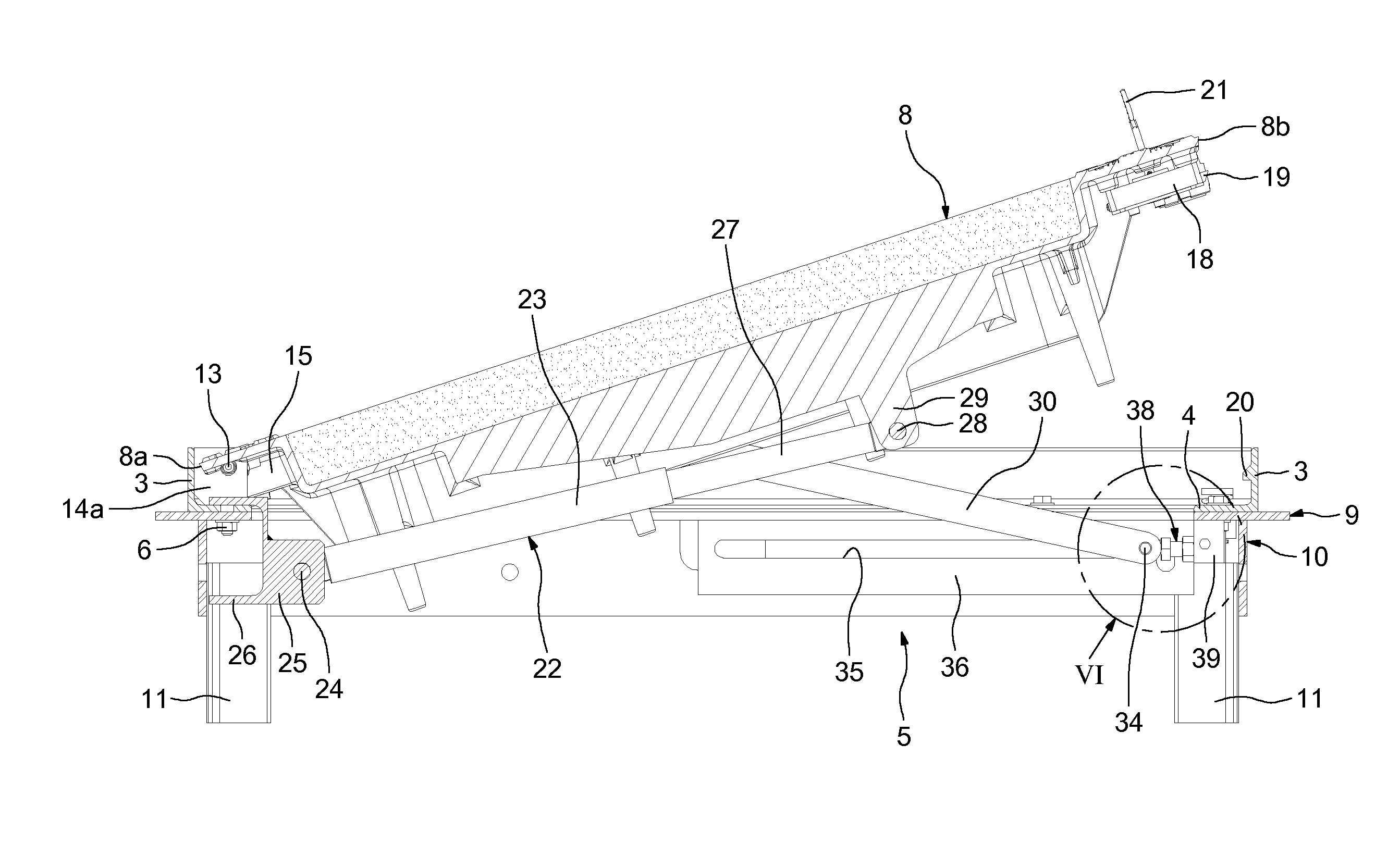

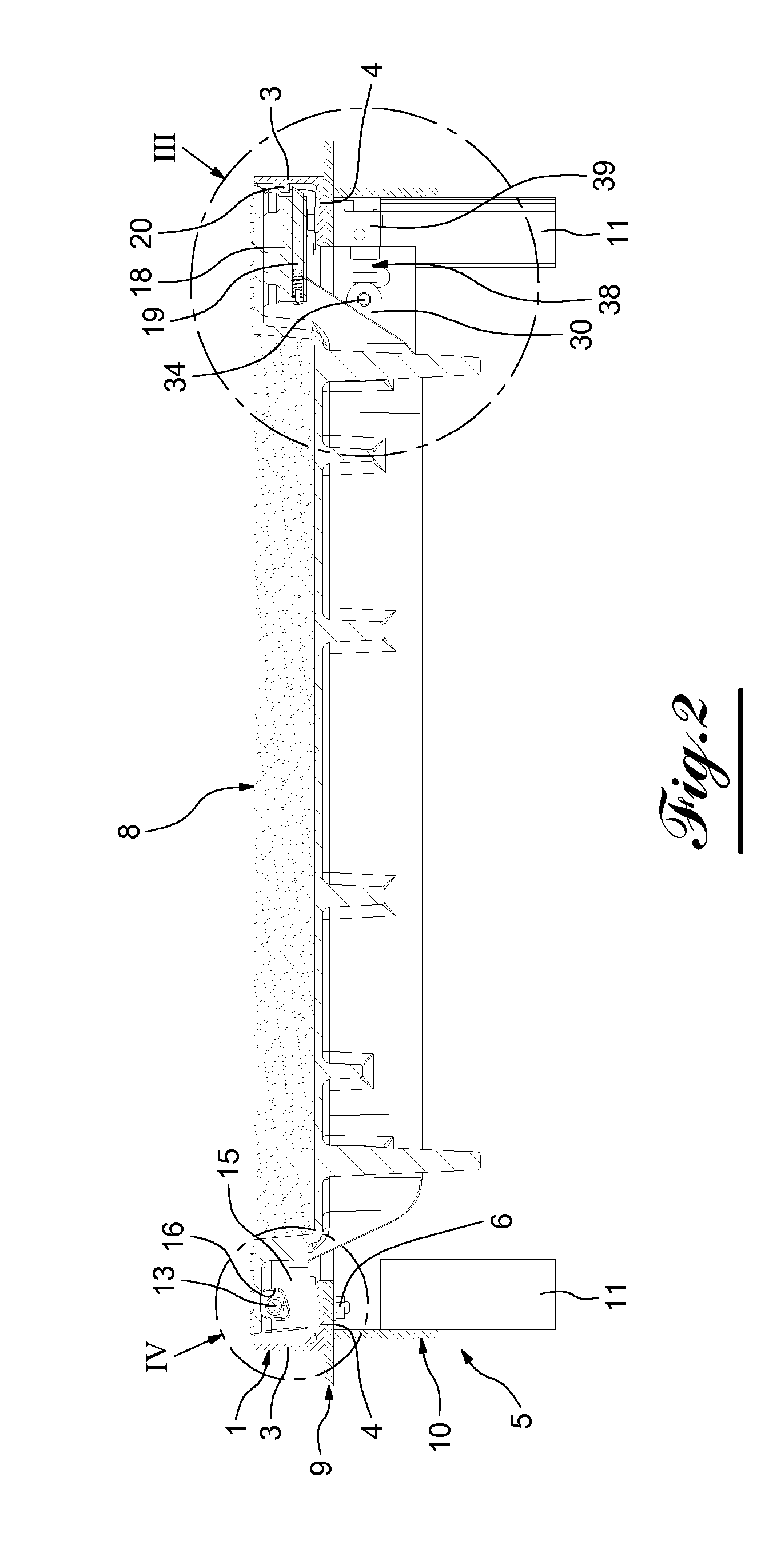

shown in FIGS. 1 to 13, the manhole cover comprises a frame 1 with a generally rectangular shape comprising two side walls 2 and two end walls 3 welded to each other and delimiting an opening.

Each side 2 and end 3 wall constitutes one of the wings of a profile with an L-shaped transverse section, the other wing 4 of which is fastened on a sub-frame 5 via fastening bolts 6.

The wings 4 associated with the side 2 and end 3 walls protrude in the opening of the frame 1 and are arranged in a same plane to constitute a peripheral seating wall 7 of a rectangular plug 8 of the manhole cover when the plug 8 is in its closed position of the opening of the frame 1 while fitting into the opening of said frame 1.

The sub-frame 5 is intended to be partially buried in the ground of a road and is made up of a flat rectangular upper frame 9 and a lower underlying skirt 10 assembled together by welding so as to have a T-shaped transverse cross-section. The wing 4 associated with each side 2 and end 3 w...

second embodiment

The manhole cover of this second embodiment is also equipped with two stops respectively associated with the two triangulated plugs 8.

Each of these stops is not shown in FIG. 14, but is identical to each stop 38 of the first embodiment and is fastened in the same way as in this first embodiment.

Thus, the stop associated with the self-locking arm 30 of the plug 8 with lock housing 18 is arranged in the corner of the sub-frame 5 opposite the joint hinges 12 of said plug protruding in the opening of the frame 1 in a direction perpendicular to the end wall 3 of the other plug substantially in a same plane as that containing the self-locking arm 30 of the lock housing 18 plug.

Likewise, the stop associated with the plug 8 not including a lock housing is fastened in the corner of the frame 5 opposite the joint hinges of said plug protruding in the opening of the frame 1 in a direction perpendicular to the end wall 3 of the plug 8 including the lock housing 18 while being situated substanti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com