Automated weightlifting spotting machine

a spotting machine and weightlifting technology, applied in the field of automatic spotting machines for weightlifting, can solve the problems of inability to provide assistance to the weightlifter, becoming weaker and more tired, and subsequently complex to us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

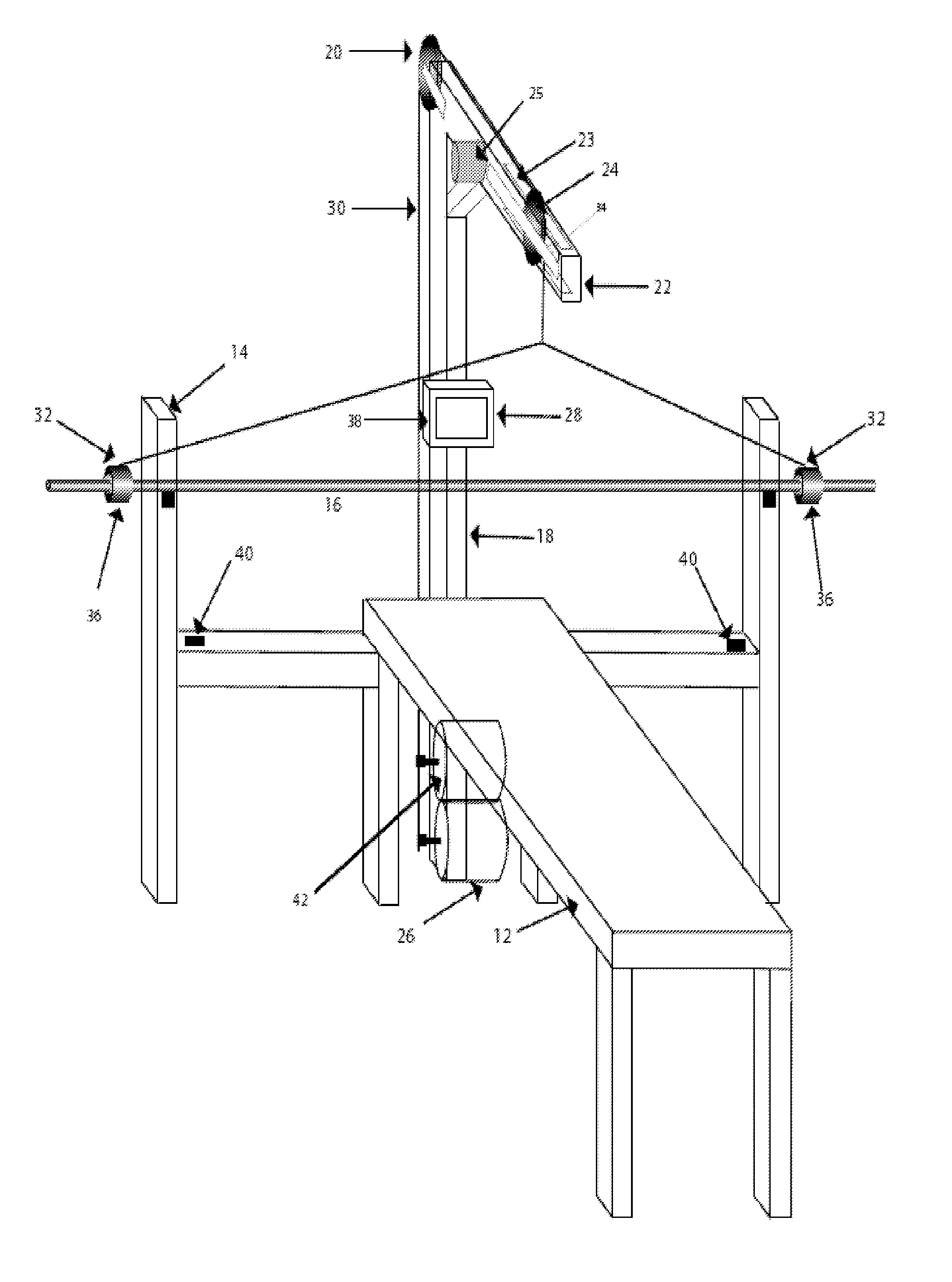

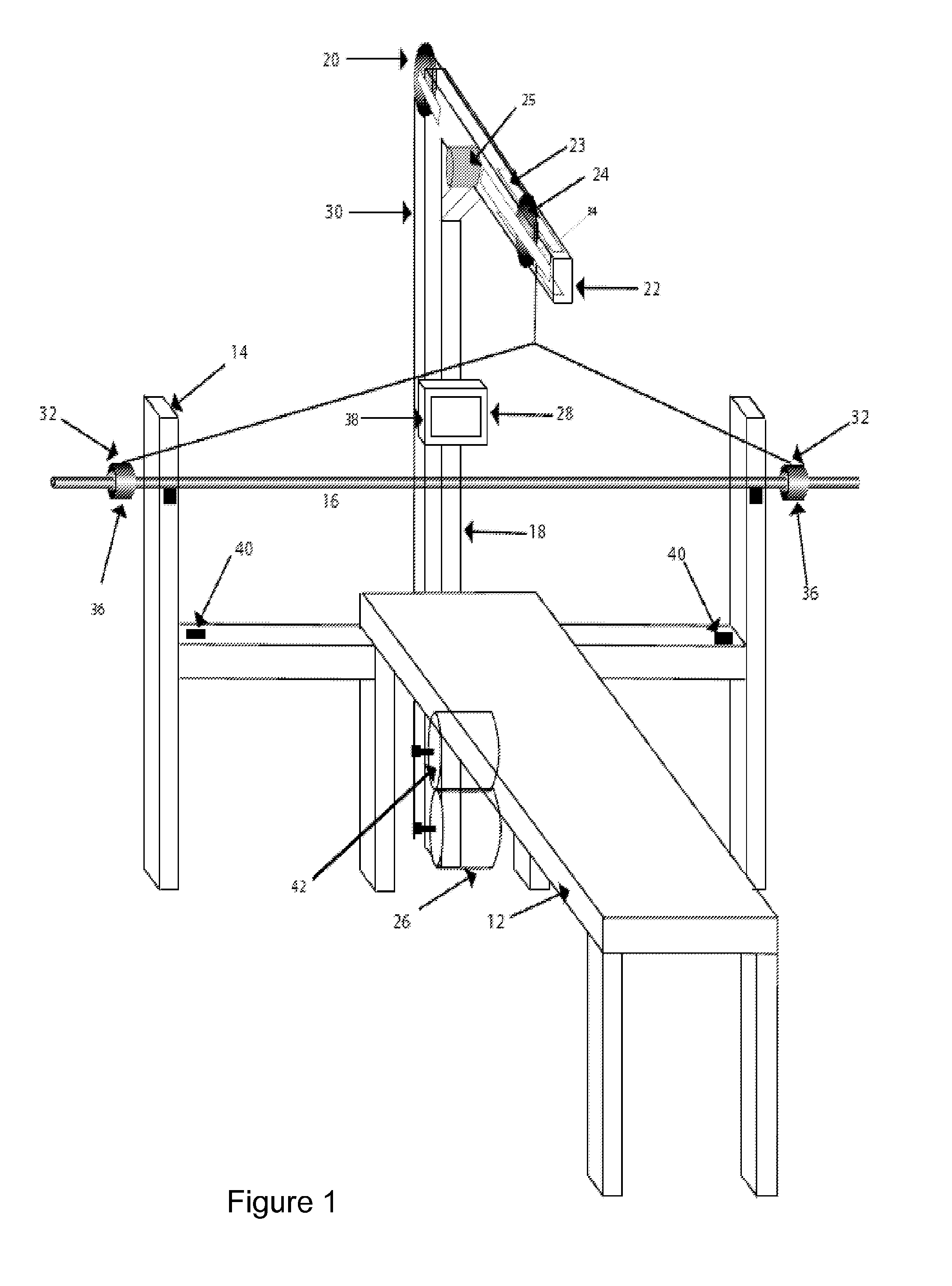

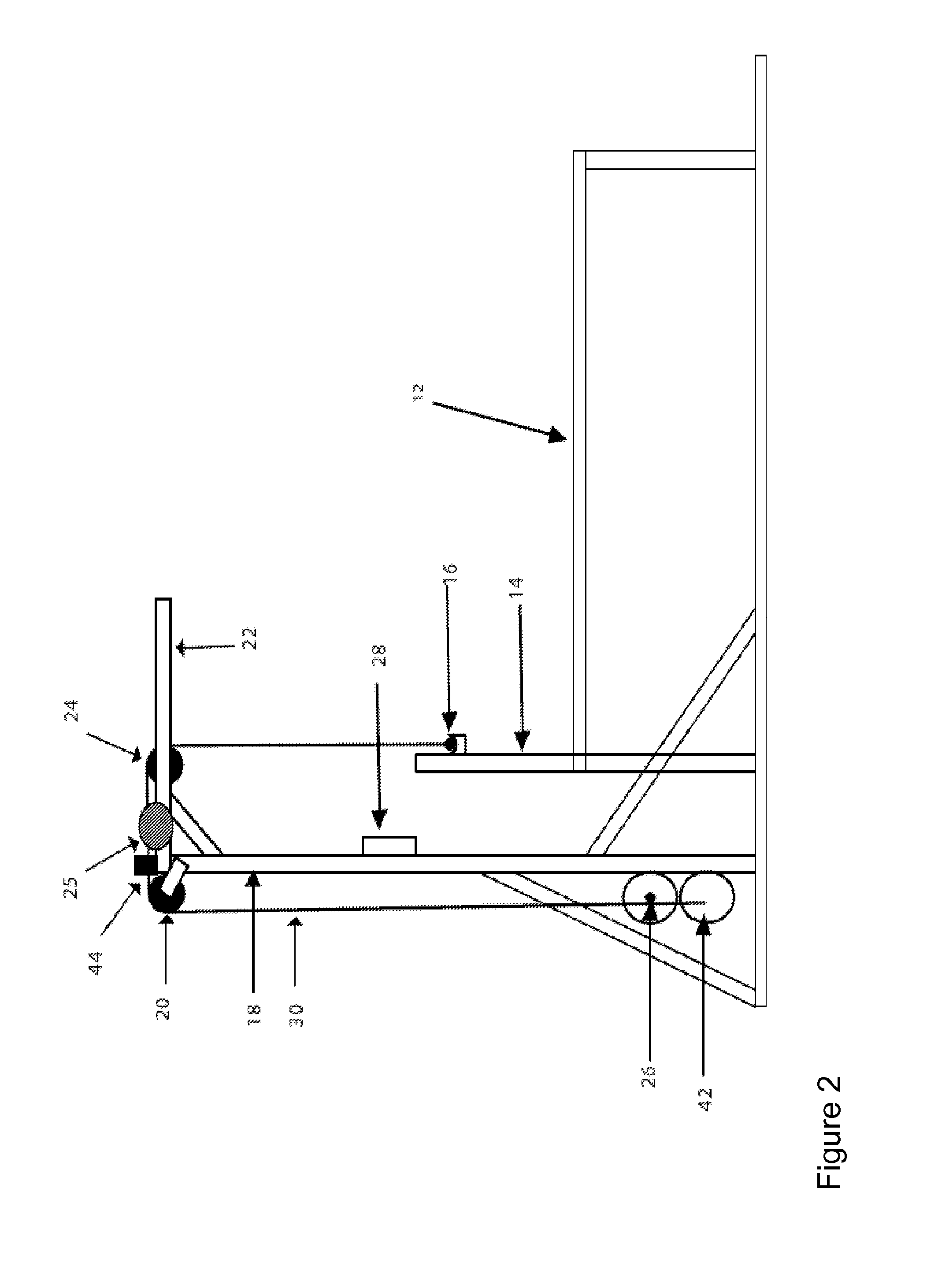

[0024]FIG. 1 shows an embodiment of the invention, in which there is shown apparatus 10, bench 12, rack 14, barbell 16, vertical support 18, pulleys 20, and 24, horizontal support 22, groove 23, motor 42, brake 26, motor 25, control panel 28, cable 30, barbell attachment means 32, sensor 34, reflective strips 36, sensor 40, sensor 44 and processor 38 (located inside control panel 28).

[0025]The apparatus 10 shown in FIG. 1 is a variation of bench press apparatus. The bench 12, rack 14 and barbell 16 are all standard pieces of equipment. The invention comprises the addition of the vertical support 18 and horizontal support 22 which define a structure, which preferably extends over the bench 12. Pulleys 20 and 24 are attached to the horizontal support 22 and pulley 24 is preferably moveable along the grove 23 powered by motor 25. A motor 26 is attached to vertical support 18 and the cable 30 runs from the motor 26, through brake 42, along the vertical support 18, over the pulley 20 alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com