Nestable cargo box for a vehicle

a cargo box and vehicle technology, applied in the direction of supplementary fittings, building locks, fastening means, etc., can solve the problems of high manufacturing and shipping costs, high shipping costs, and mounting costs of cargo boxes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

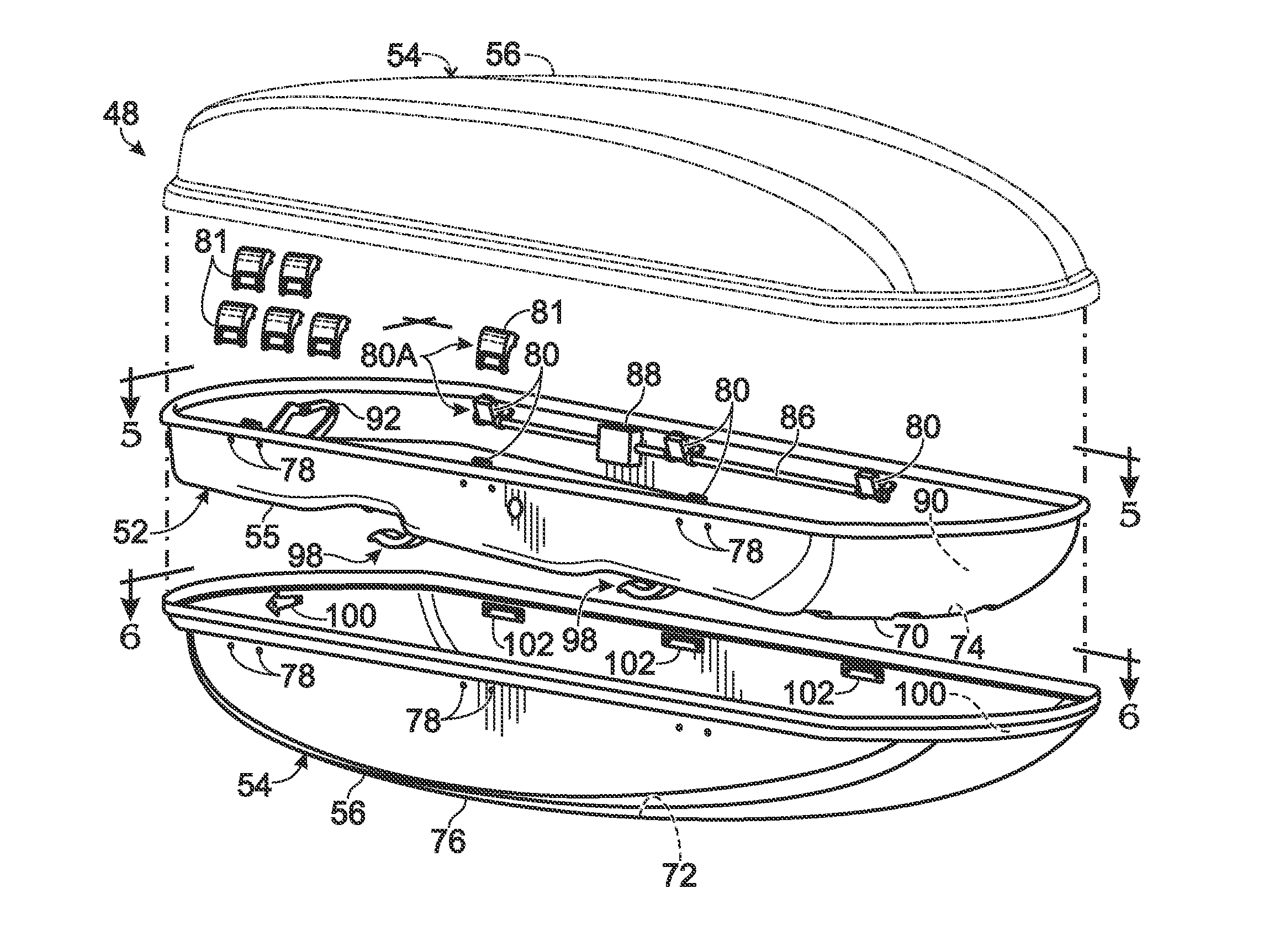

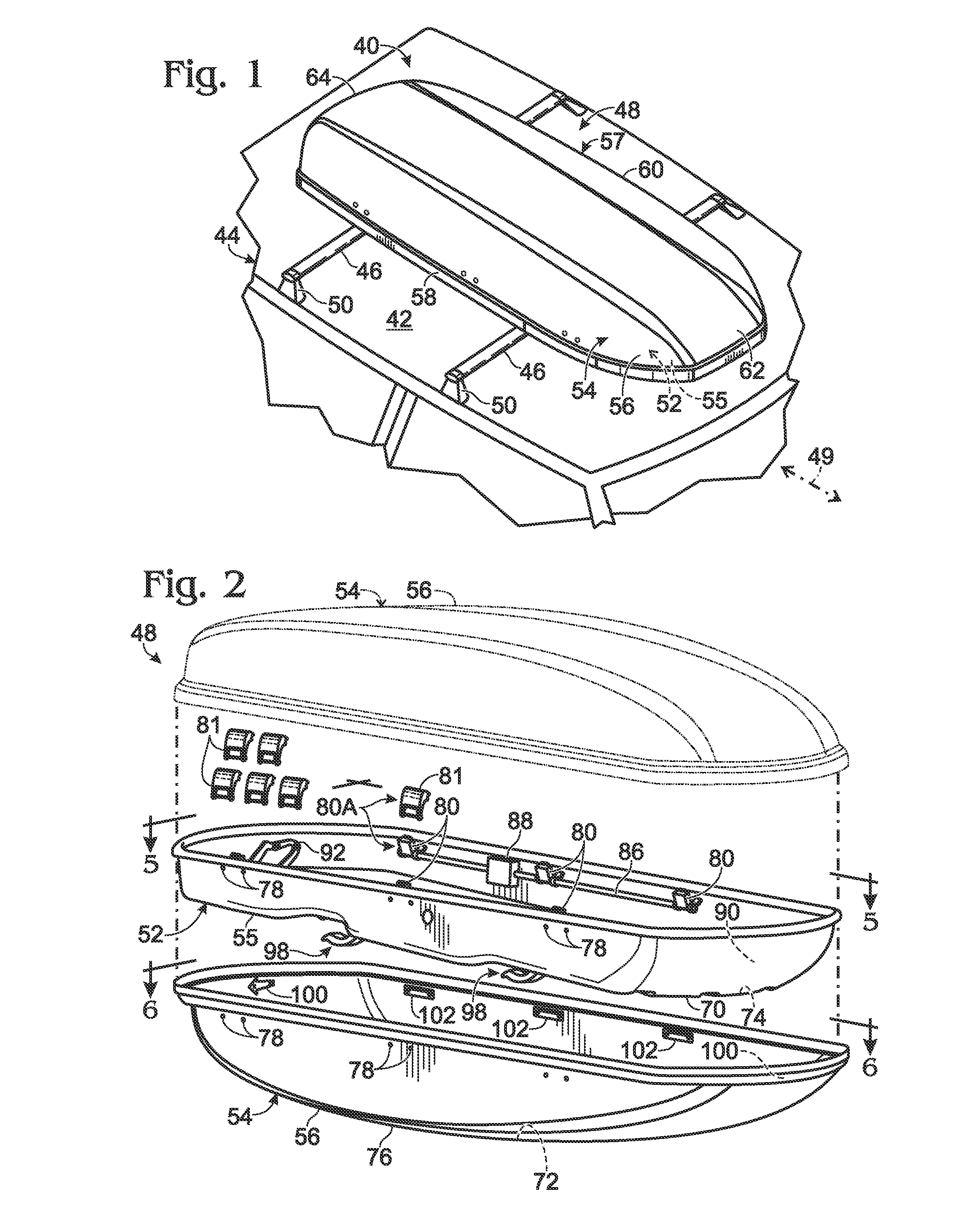

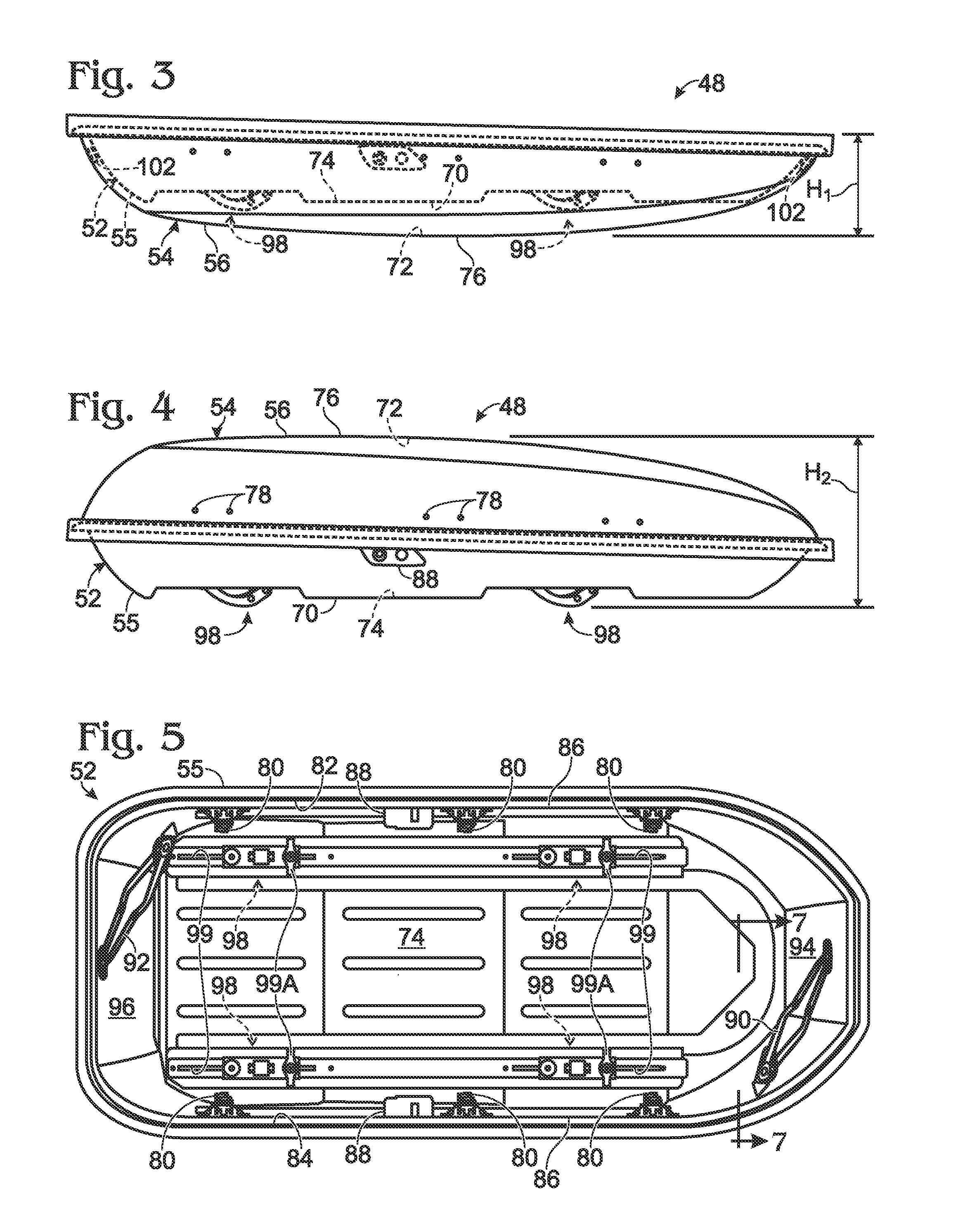

[0033]The present disclosure provides a vehicle rack system with a nestable cargo box, including a kit for constructing the cargo box, and methods of making, packaging, shipping, supplying, and assembling the cargo box. The cargo box may include a base portion and a lid portion that can be arranged in (1) a shipping configuration where the base and lid portions are not operatively connected to each other and one of the portions is inverted and nested in the other portion and (2) an operative configuration in which the base and the lid portions are operatively connected to each other to form a box that can be pivoted open and fastened shut. The base and lid portions may be connected to each other in the operative configuration by snap-fit connections that mount at least part of a hinge assembly, a latch assembly, a strut assembly, or a combination thereof, to the base portion and / or the lid portion of the cargo box.

[0034]The nestable cargo box can be shipped to a consumer in a partia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com