Intake and Exhaust Method and A Structure Utilizing the Same

a technology of intake and exhaust, which is applied in the direction of ventilation systems, heating types, lighting and heating apparatuses, etc., can solve the problems of turbulence generated, waste of energy, and insufficient heat in the interior space, and achieve the effect of improving air exchange rate and improving air exchange capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

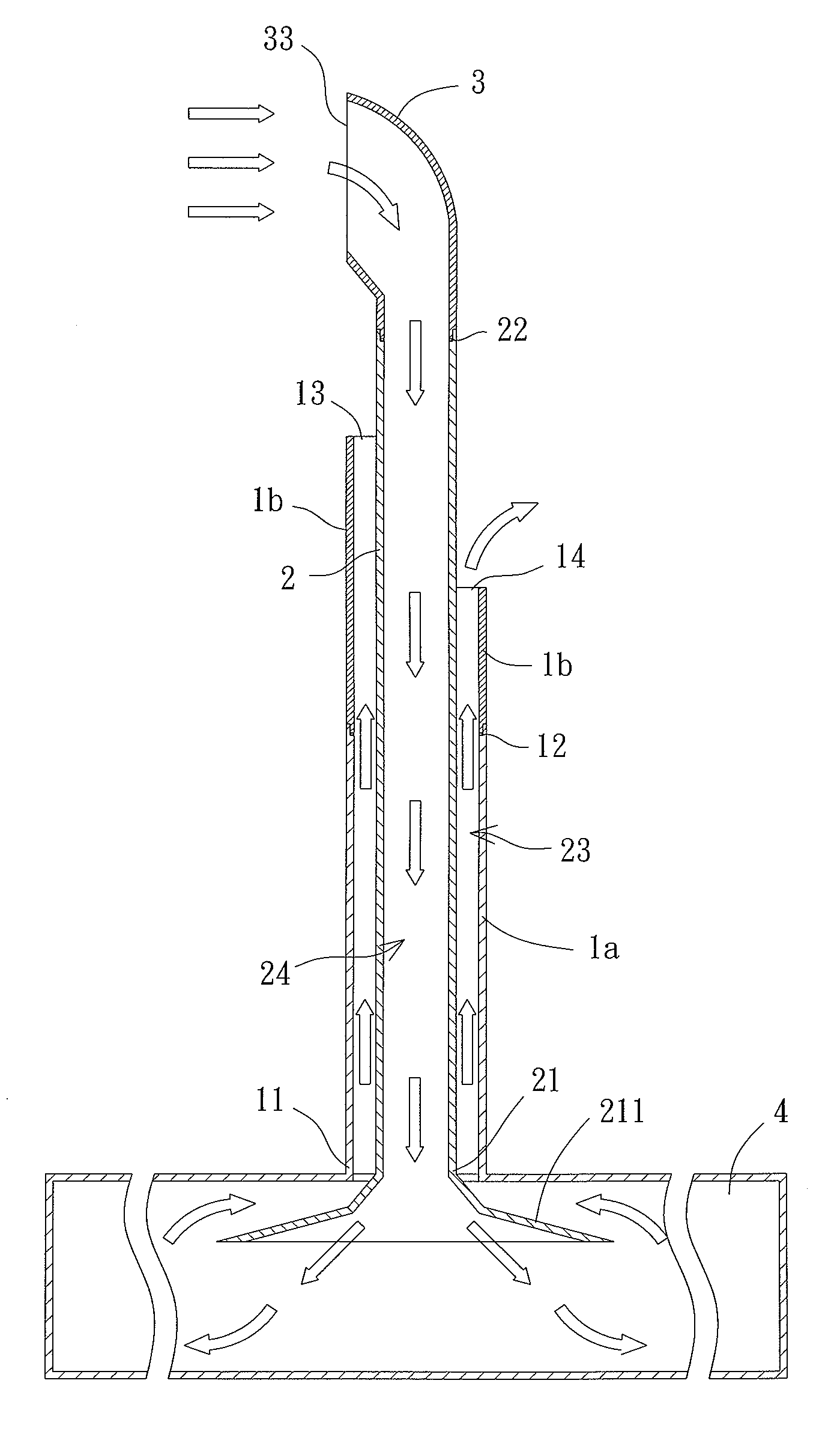

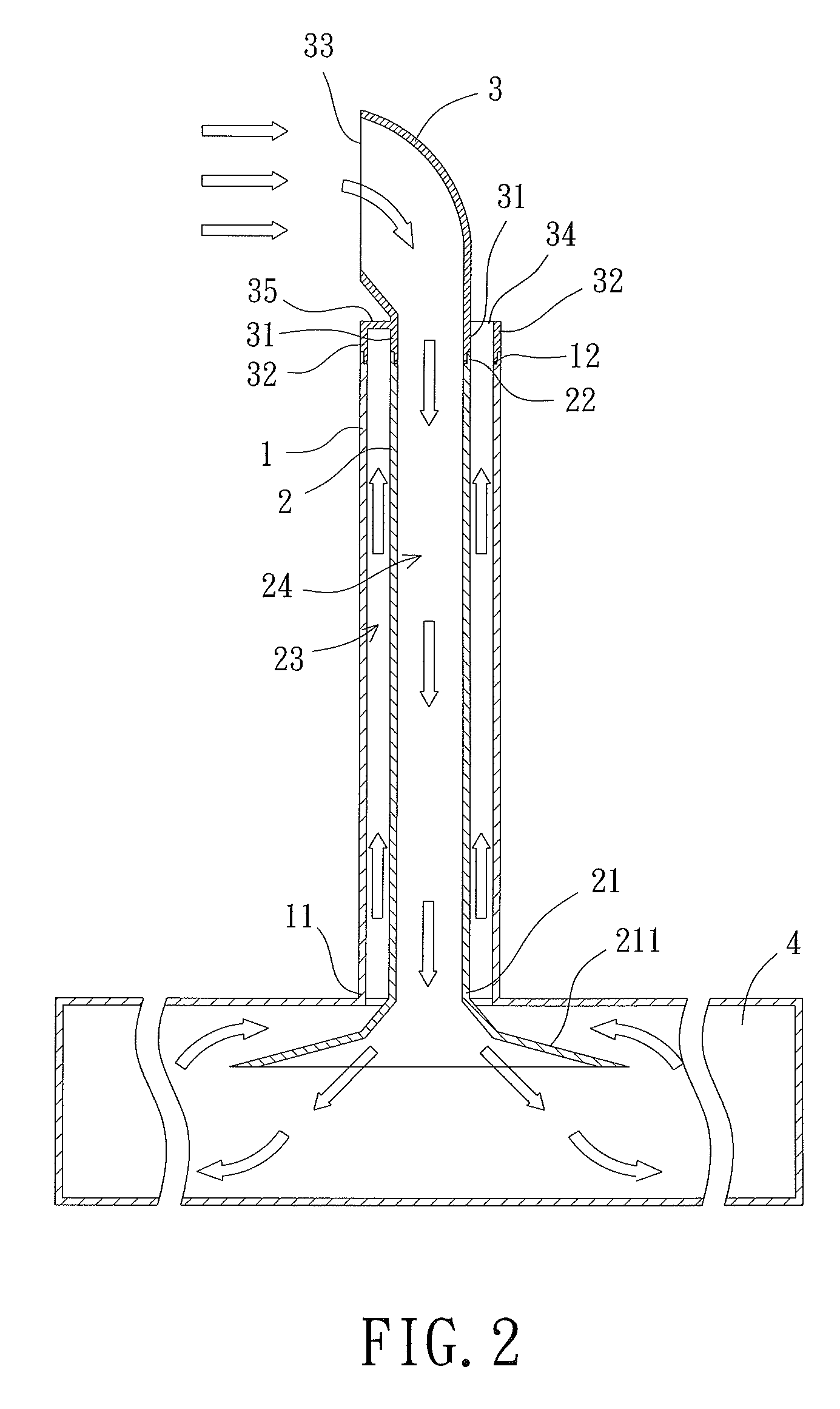

[0017]Referring to FIG. 2, an intake and exhaust structure using an intake and exhaust method is disclosed according to a first embodiment of the invention. The intake and exhaust structure includes an outer duct 1, an inner duct 2 and an air-guiding cover 3. The outer duct 1 has an air channel and may have a cross section in any shape, such as a circular shape adopted in this embodiment. In addition, the outer duct 1 has a first end 11 and a second end 12, and the inner duct 2 has a first end 21 and a second end 22. The air-guiding cover 3 is coupled with the second ends 12 and 22 of the outer duct 1 and the inner duct 2.

[0018]The inner duct 2 is disposed in the outer duct 1 and may have a cross section in any shape, such as a circular shape adopted in this embodiment. A circular air channel 23 is defined between the outer duct 1 and the inner duct 2. The inner duct 2 further comprises an intake air channel 24. In addition, the inner duct 2 may have an air-spreading member 211 at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com