Shock absorption air changing mattress cushion

A technology for seat cushions and mattresses, which is applied in the field of shock-absorbing and ventilating mattress cushions, can solve the problems of inability to adjust the elastic bearing force of the "spring in the spring", troublesome disassembly and assembly of the cushion body, accumulation of dust and debris on the mesh bed, etc. The effect of improving the air convection exchange, easy disassembly and replacement, and avoiding the accumulation of debris and dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

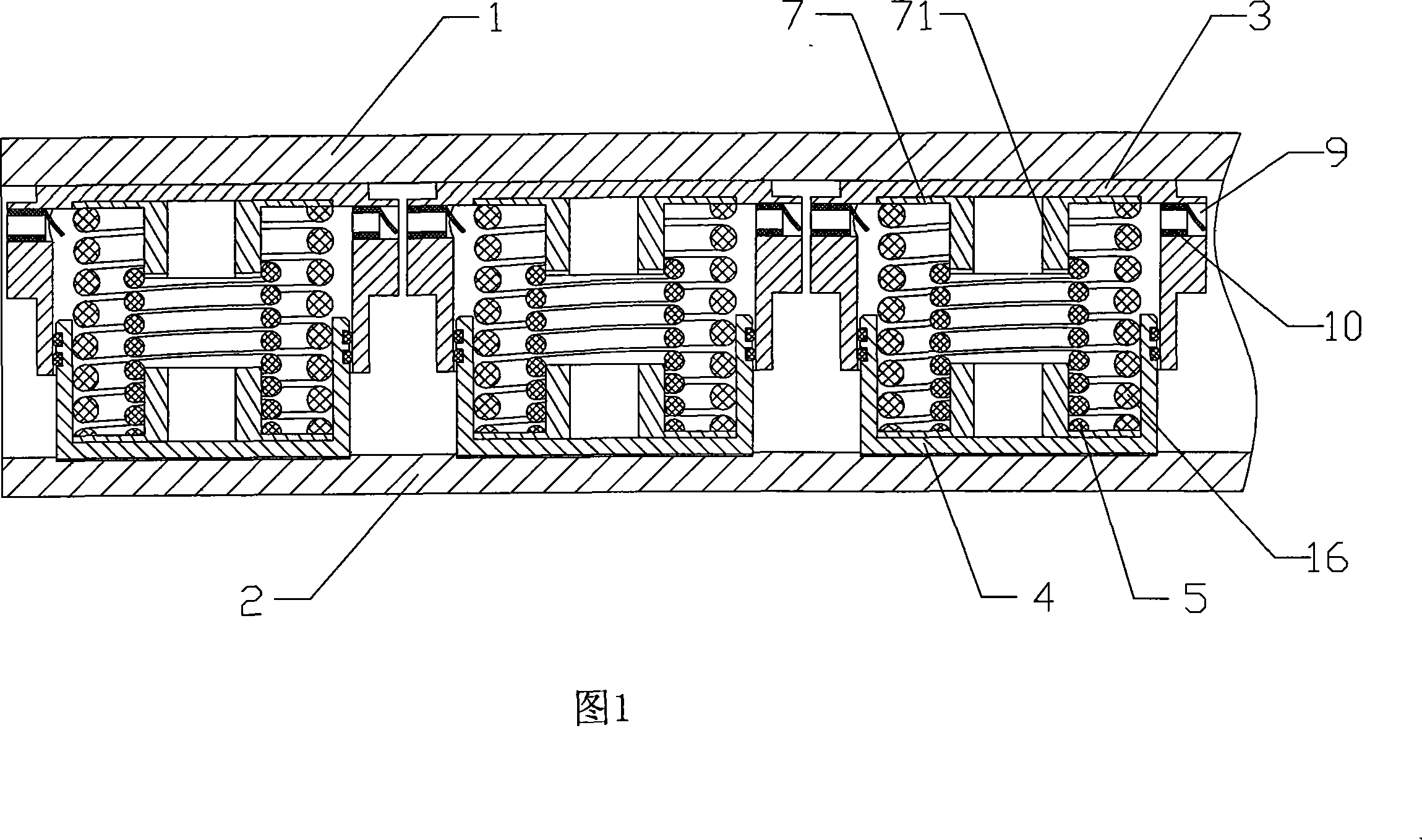

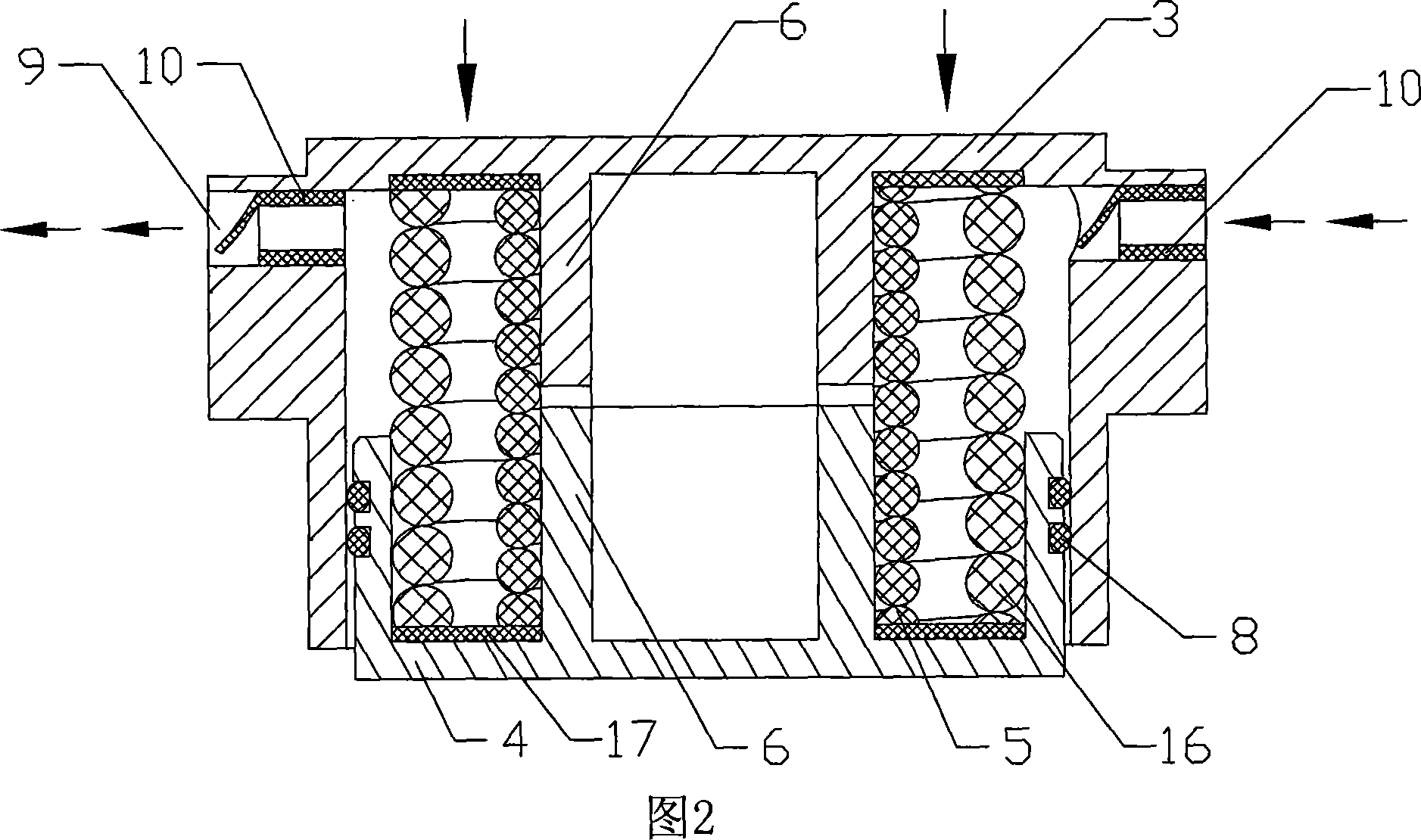

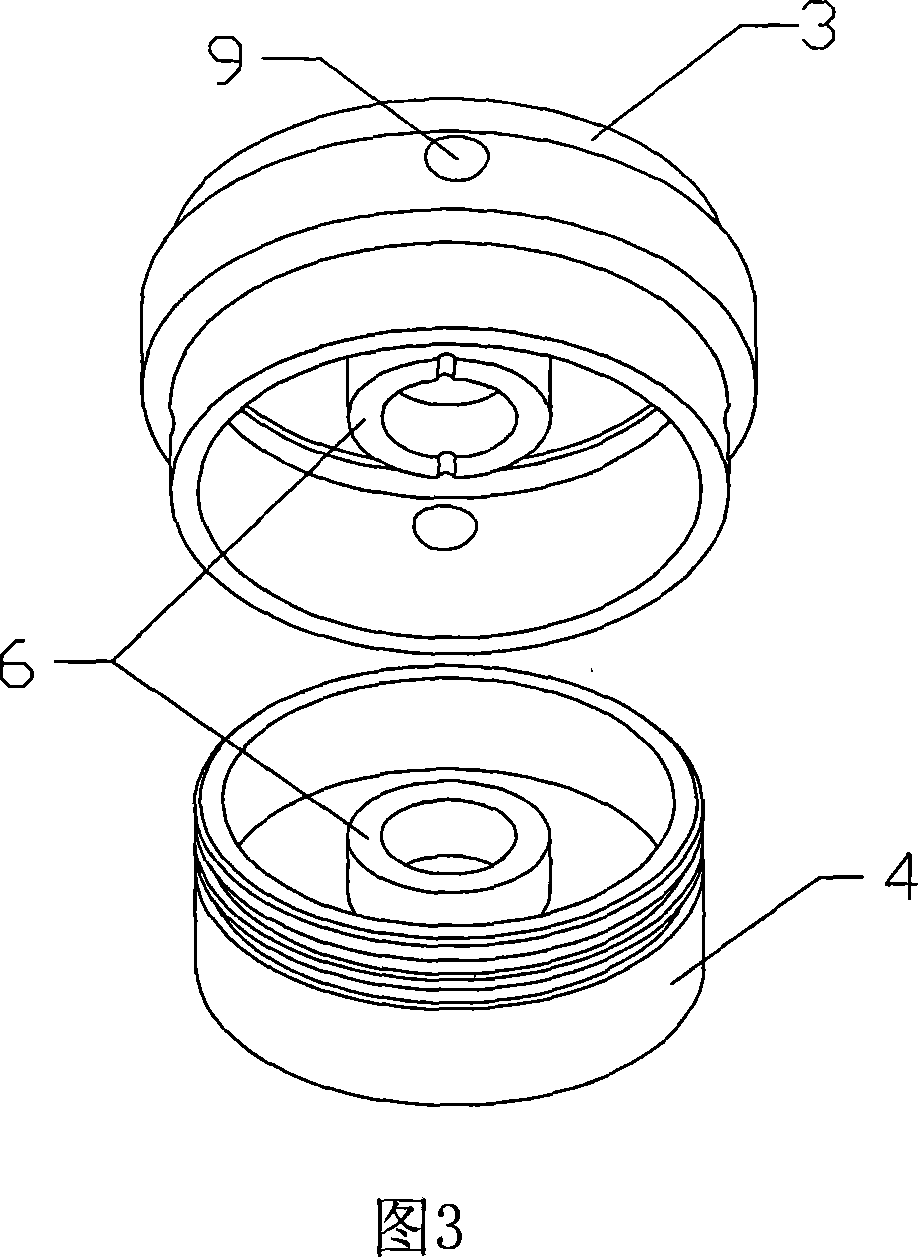

[0038] The present invention will be further described below in conjunction with the accompanying drawings.

[0039]According to Fig. 1 to Fig. 10, Fig. 13 to Fig. 16, the cushion of shock-absorbing ventilating mattress of the present invention comprises an upper cushion body 1 and a lower cushion body 2, and the upper cushion body 1 and the lower cushion body 2 are generally Mattresses and cushions are used for mattress pads or plate pads, and an outer cover 3 and an inner cover 4 are installed between the upper pad body 1 and the lower pad body 2. The outer cover 3 and the inner cover 4 are supported by an elastic member, and the elastic member includes at least one inner spring 5 coaxially arranged with the outer cover 3 and the inner cover 4. Shock elastic effect, can be provided with the outer spring 16 coaxial with it outside inner spring 5, as shown in Figure 1, Figure 2, Figure 4, Figure 6, Figure 7, Figure 8, Figure 13 and Figure 14, or outer The spring 16 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com