Sealing cover

a sealing cover and cover technology, applied in the field of sealing covers, can solve the problems of adverse effects of sealing effect and difficulty in removal of sealing cover from the box body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

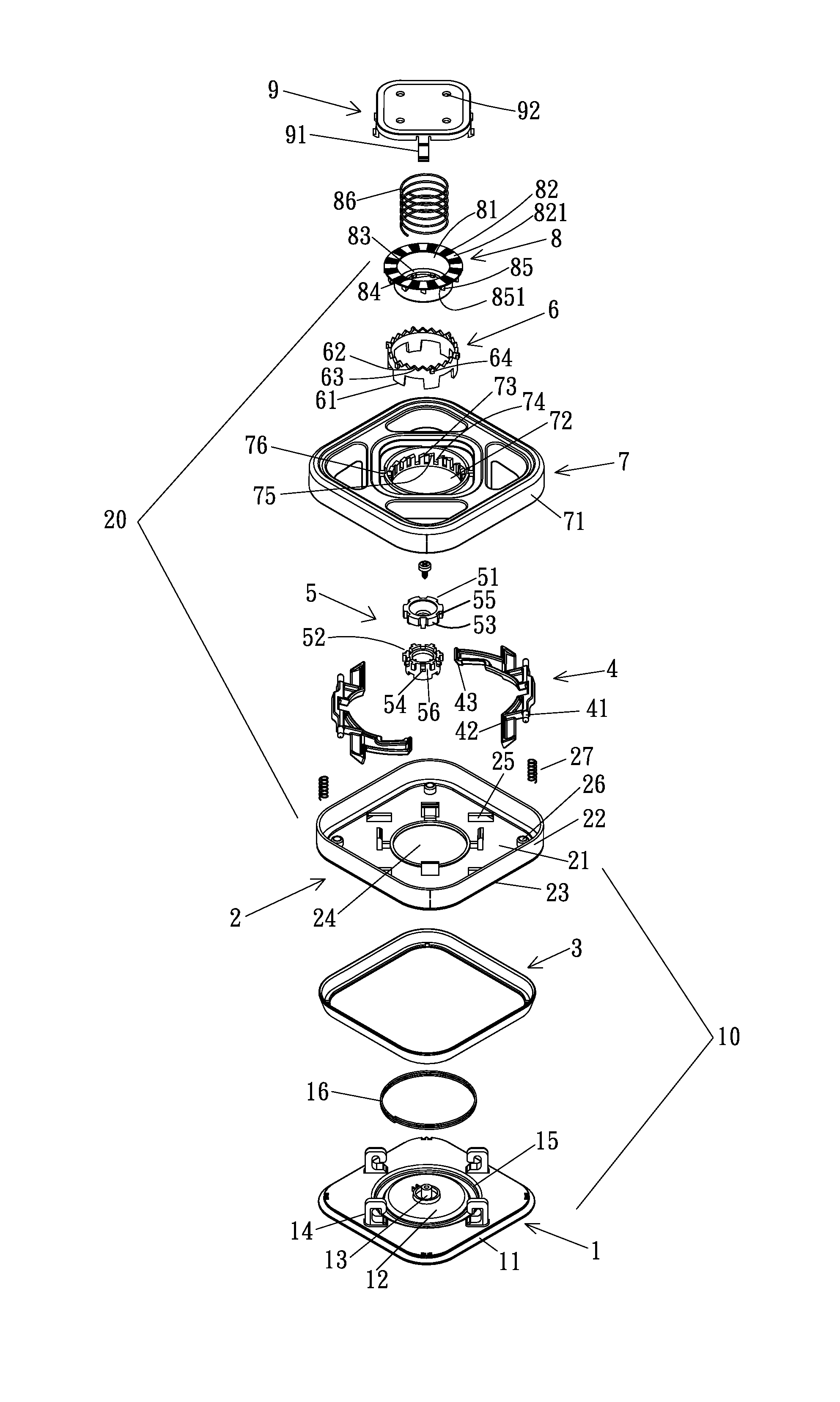

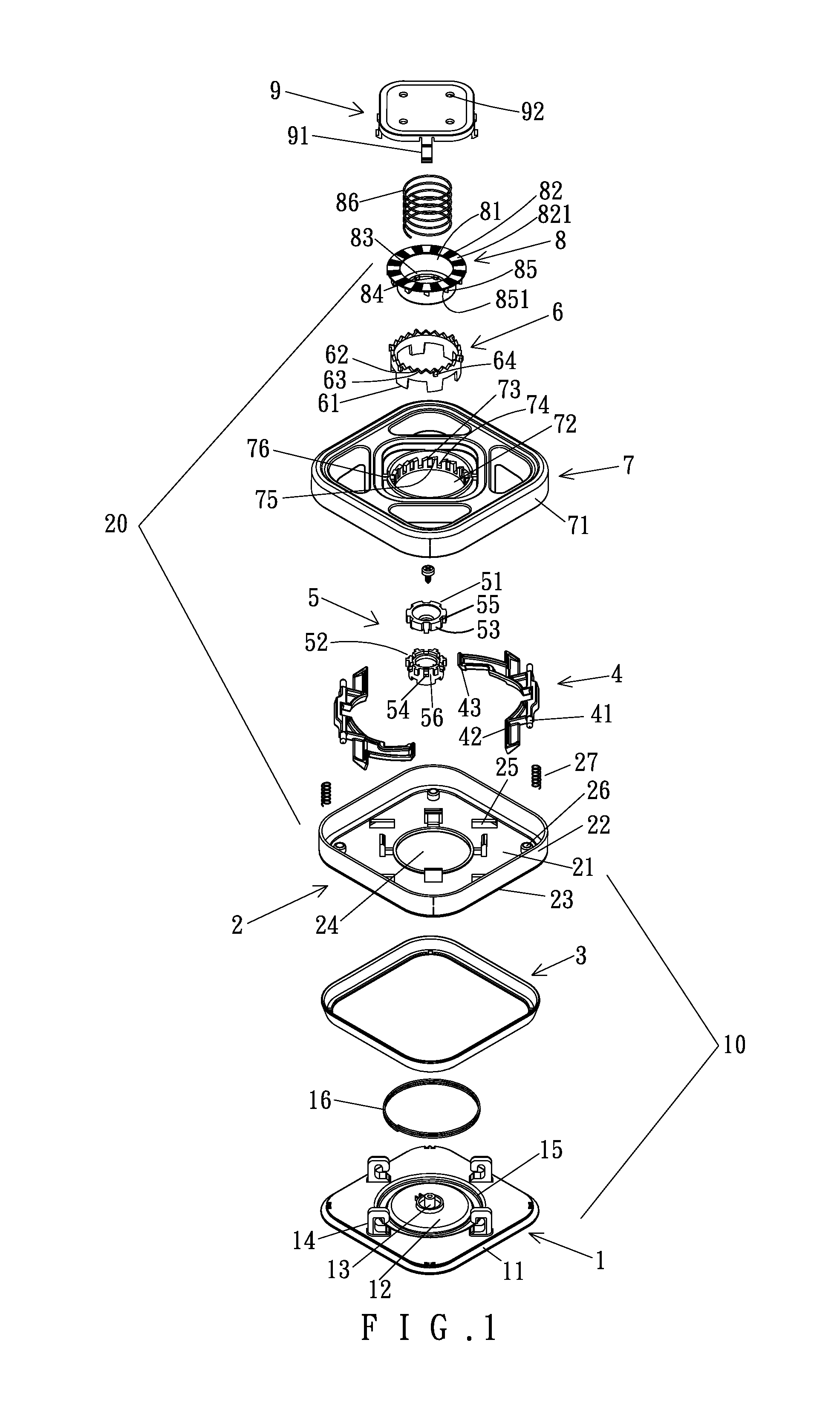

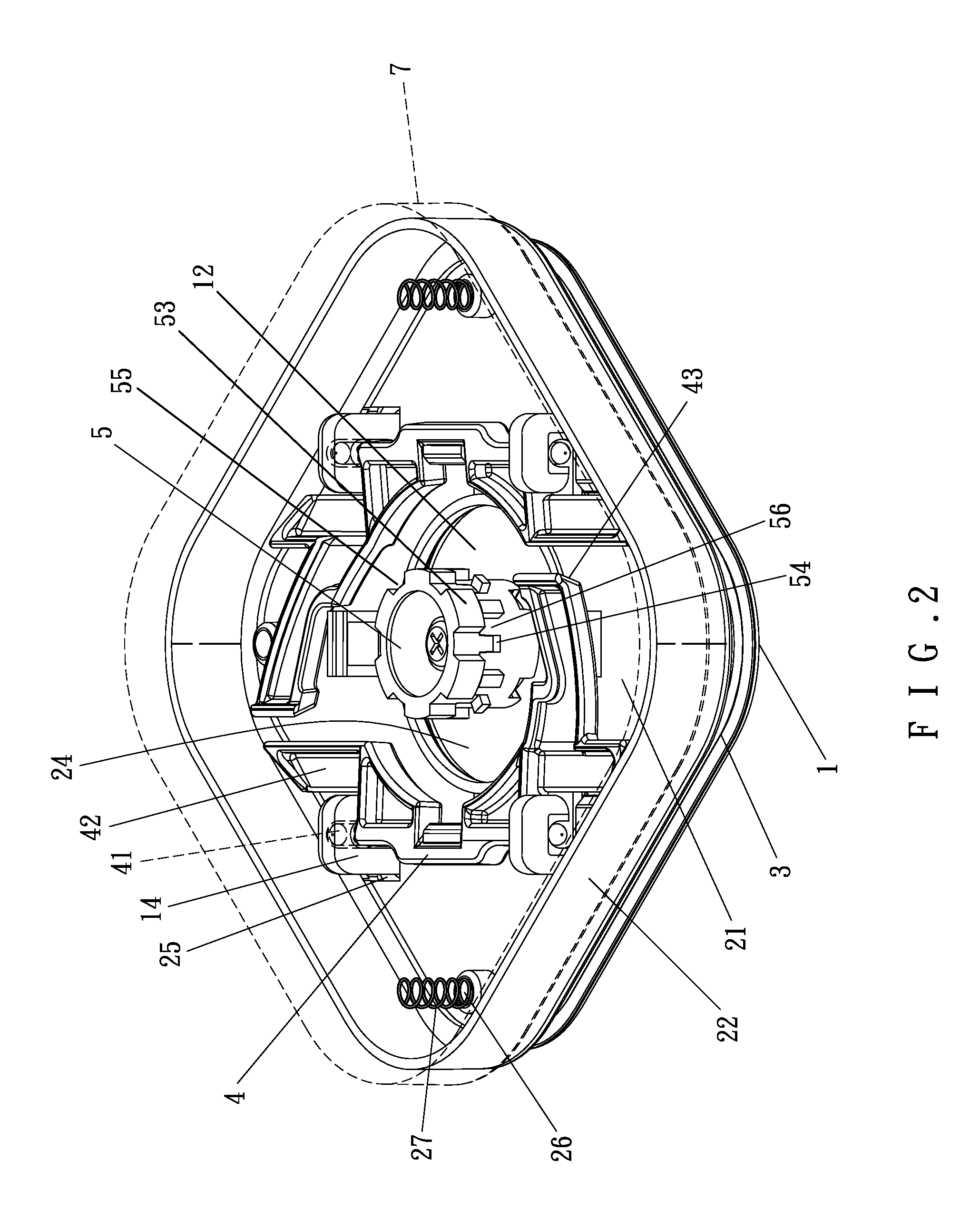

[0021]FIGS. 1-5 show a sealing cover according to the present invention in an unsealing state. The sealing cover includes a base 1, a lower lid 2, a gasket 3, two supports 4, a seat 5, a pressing member 6, an upper lid 7, a positioning ring 8, and a shield 9. The base 1, the lower lid 2, and the gasket 3 form a sealing unit 10. The seat 5, the pressing member 6, the upper lid 7, and the positioning ring 8 form a control unit 20. The base 1 includes an outer periphery having an engagement edge 11. The base 1 further includes a central portion having an abutment face 12 and an engaging portion 13. A plurality of pivotal columns 14 and an annular groove 15 are defined in a top face of the base 1. A first spring 16 is received in the annular groove 15 and abuts a bottom wall of the annular groove 15.

[0022]The lower lid 2 is mounted on top of the base 1 and includes a bottom wall 21 and an annular wall 22 formed along an outer periphery of the bottom wall 21, with an engagement edge 23 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com