Glove for gripping small object

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

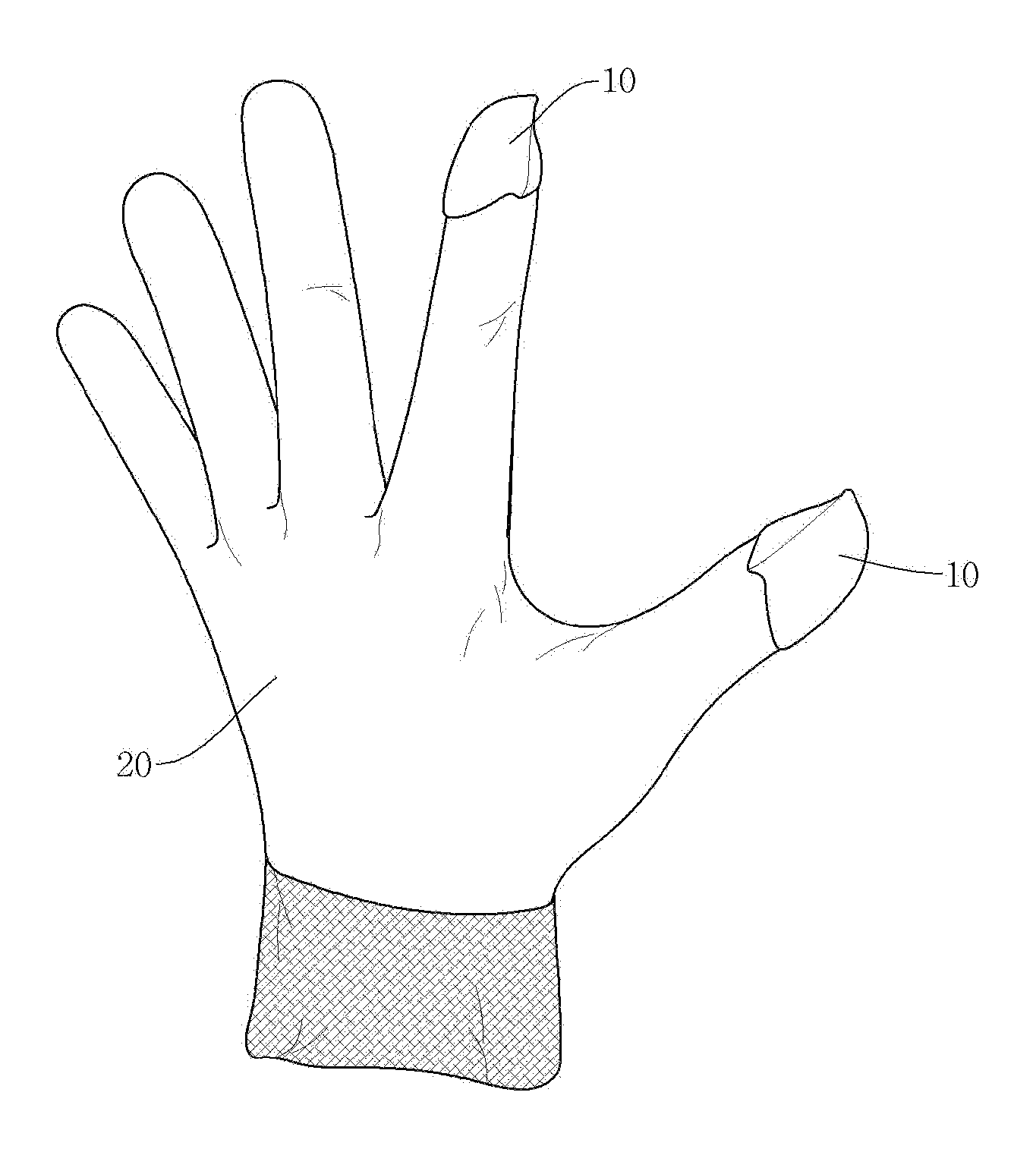

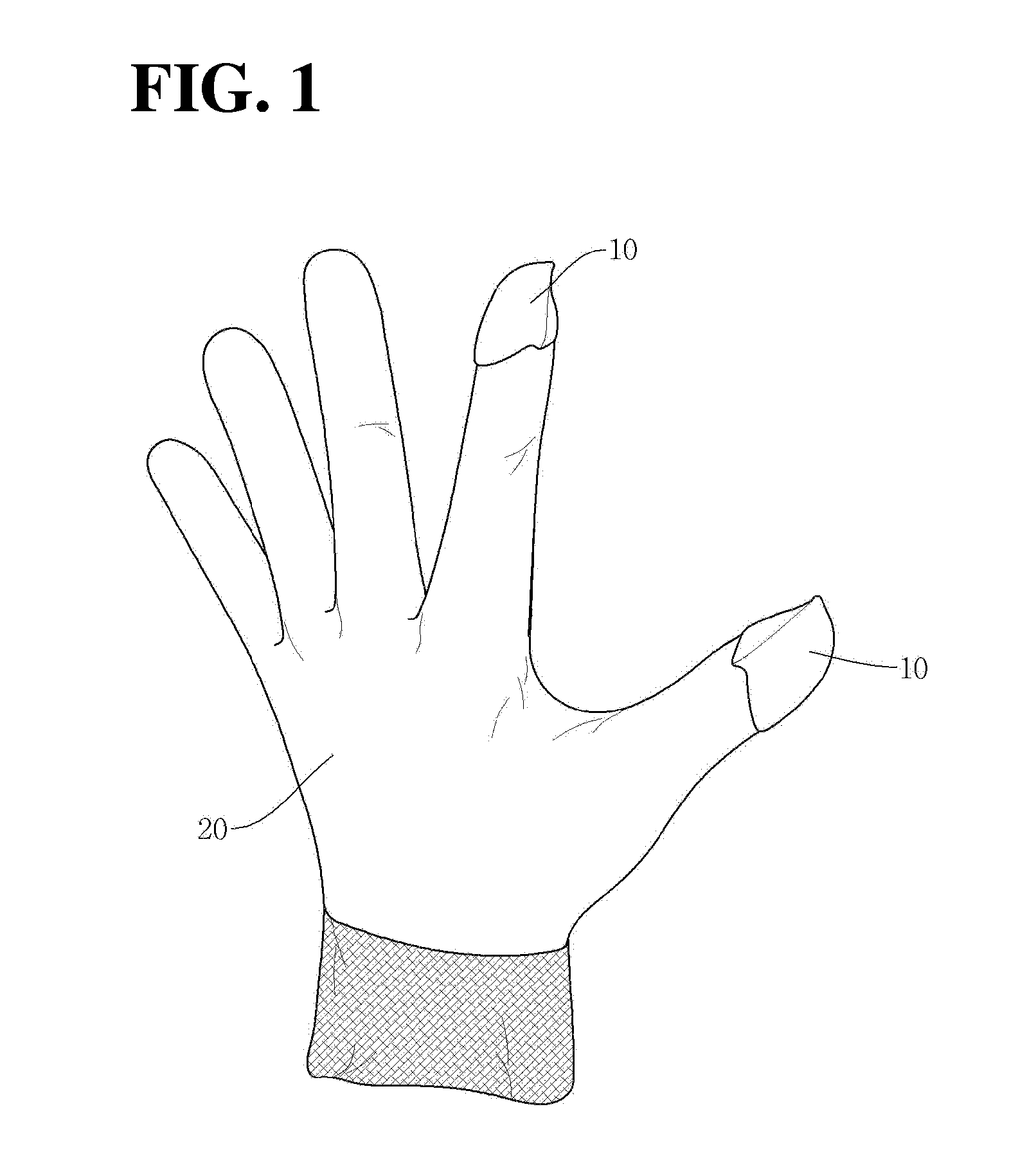

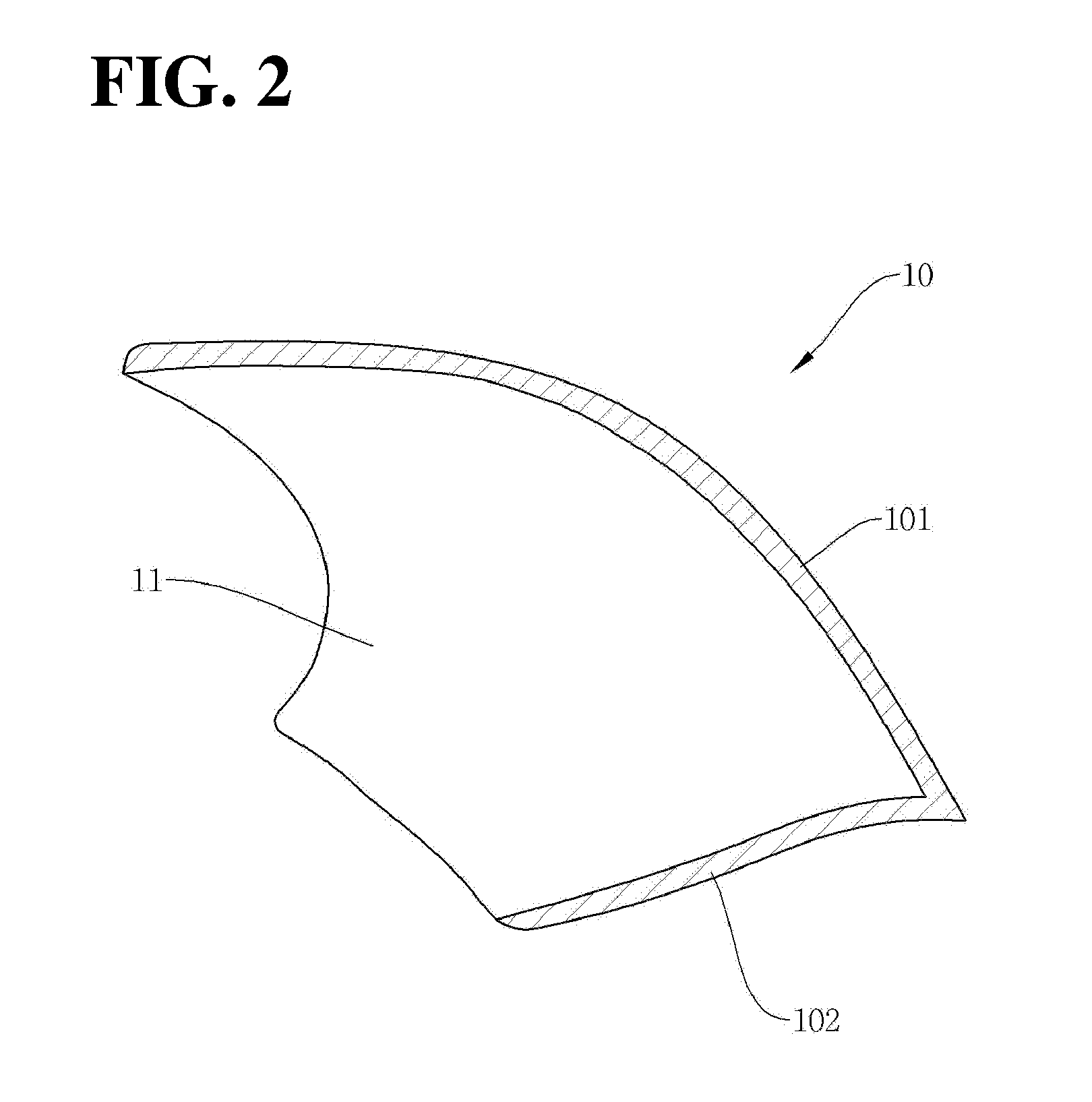

[0039]Hereinafter, with reference to accompanying drawings, examples of the present invention will be described in detail. For convenience, like reference numerals refer to like elements throughout. FIG. 1 is a perspective view of a glove for gripping a small object according to the present invention, and FIG. 2 is a cross-sectional view taken along line I-I′ of FIG. 1.

[0040]With reference to FIG. 1 and FIG. 2, a glove for gripping a small object according to the present embodiment includes a glove main body 20 including a finger potion for covering a finger, and a thimble portion 10.

[0041]The thimble portion 10 is formed at an end portion of the finger portion of the glove. The thimble portion 10 includes a first layer 101 facing the back of a hand and a second layer 102 being opposite to the first layer 101. Front sides of the first layer 101 and the second layer 102 are adhered to each other and form a structure where the finger is inserted. In this instance, the thimble portion ...

second embodiment

[0057]FIG. 5 is a structural view of a glove for gripping a small object according to the present invention.

[0058]In the embodiment, at least a part of a portion where a second layer 102 of a forefinger thimble portion 10-2 is mounted has a hole 201, and a finger of a user is in direct contact with the forefinger thimble portion 10. In this instance, the forefinger thimble portion includes a conductive resin, and thus, a current of the finger of the user is transferred to the touch screen through the forefinger thimble portion, thereby generating the capacitance change of the touch screen.

[0059]In this instance, widely known moldable conductive resin may be used the conductive resin. A material that a conductive metal and resin are mixed is generally used. For example, iron, cupper, nickel, and so on may be used for the metal, and PPE, PC, and so on may be used for the resin.

third embodiment

[0060]FIG. 6 is a structural view of a glove for gripping a small object according to the present invention.

[0061]In the embodiment, a stylus pen is mounted on the first layer 102. That is, the stylus pen is mounted in the first layer 102. The stylus pen may be integrated with the thimble portion during an injection molding, or may be detachable to the thimble portion.

[0062]The stylus pen includes a battery 302, and a conductive tip 301 for transferring the current of the battery. Also, a connection element for connecting the battery 302 and the conductive tip 301 may be further included.

[0063]The battery 302 is a small size battery having a size being able to be included in the first layer. The conductive tip 301 has a stick shape extending in the finger direction. Also, the front end portion of the conductive tip 301 may be preferably consistent with or aligned with the front end portion of the thimble portion.

[0064]FIG. 7 is a structural view of a glove for gripping a small objec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com