Ground engaging shaft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

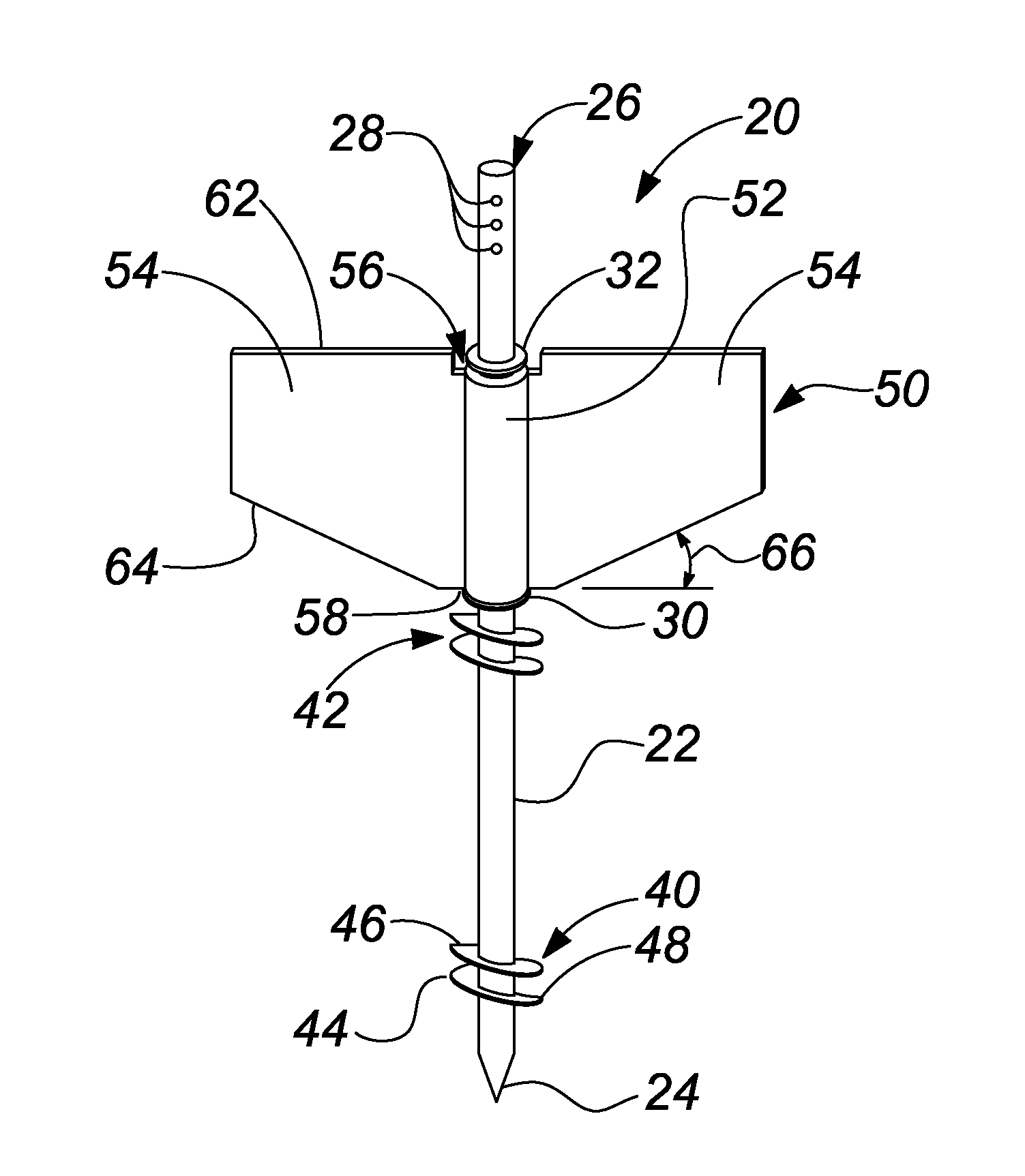

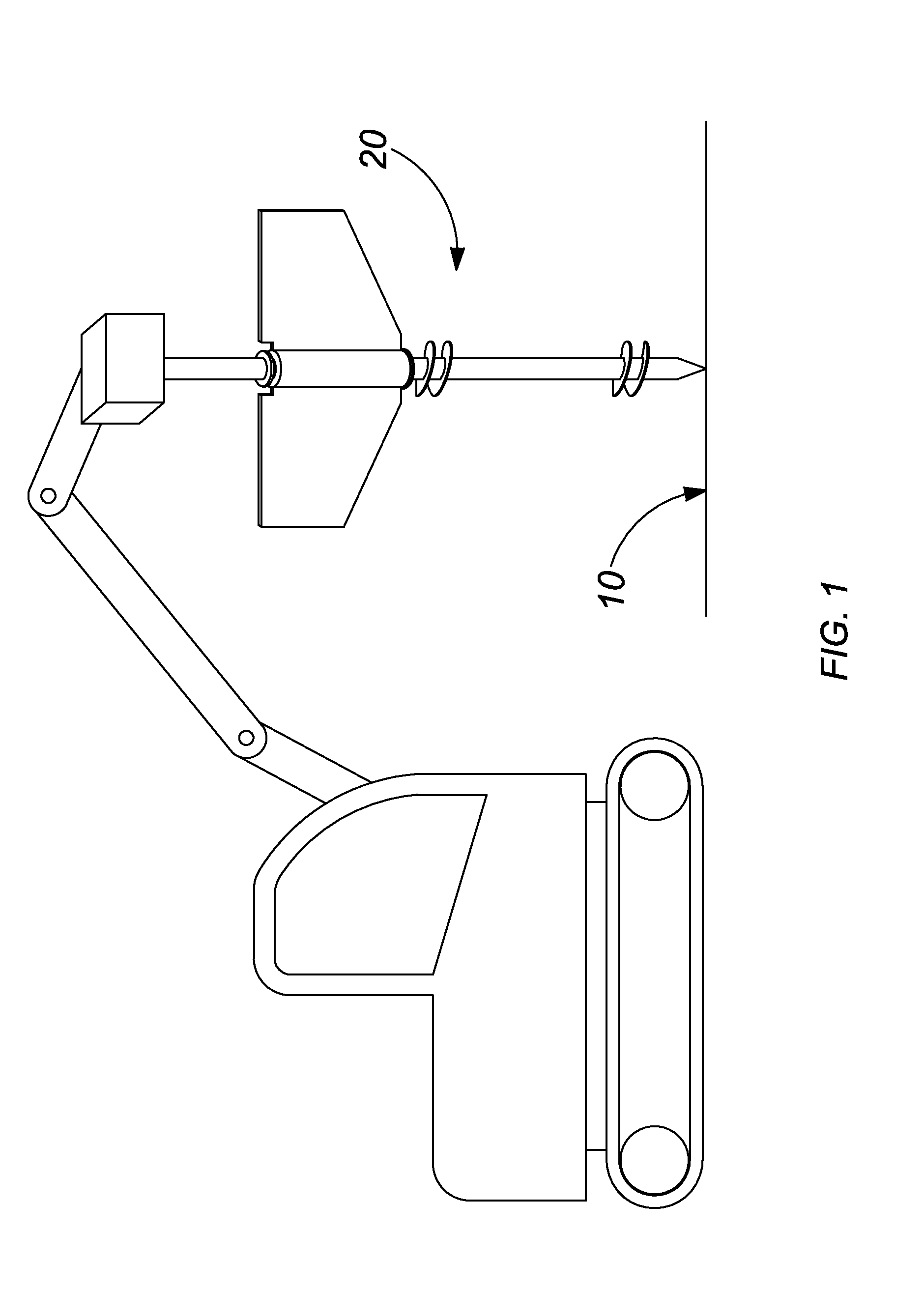

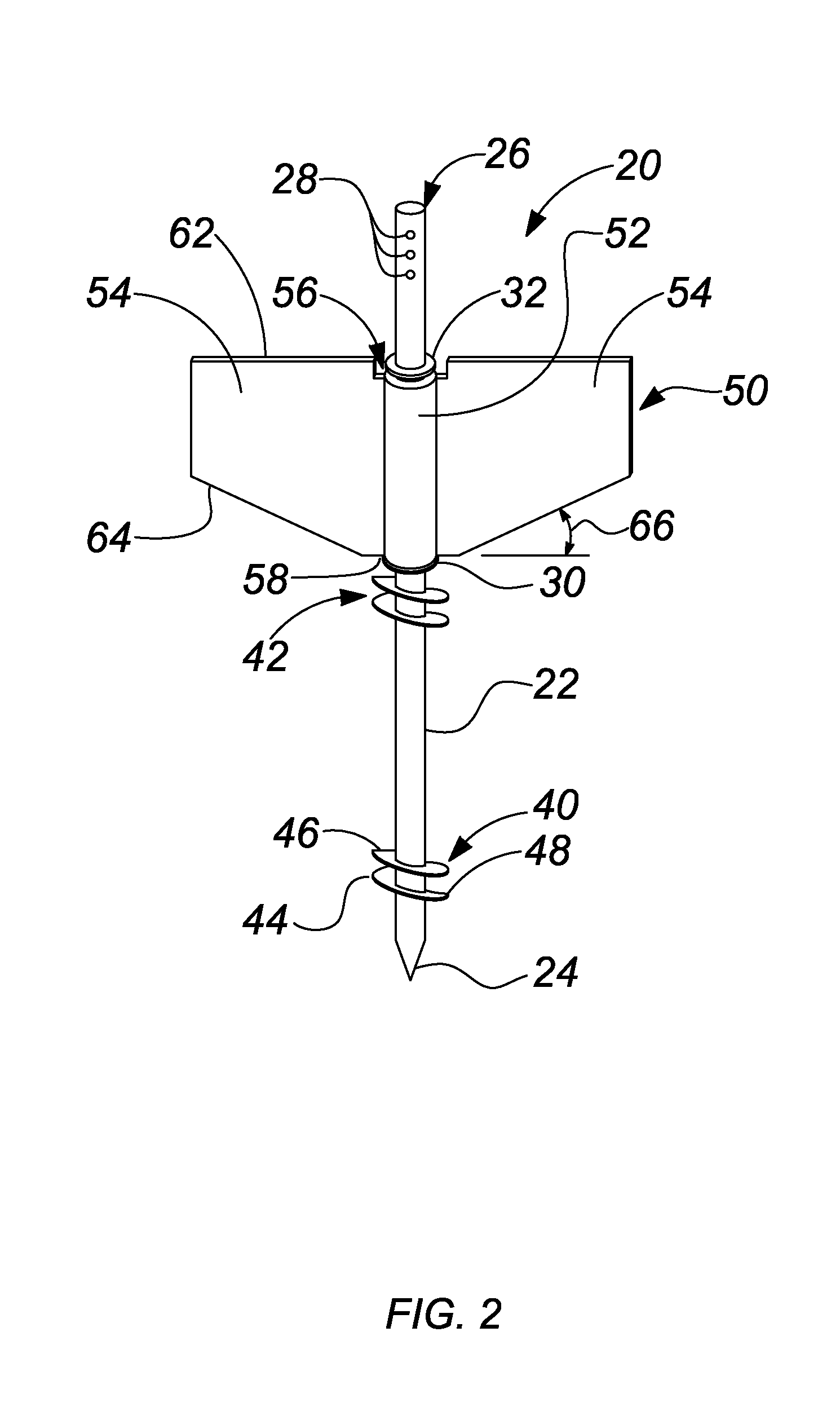

[0027]With reference to FIG. 1, an apparatus for engagement within a soil formation 10 according to a first embodiment of the present invention is generally illustrated at 20. The apparatus comprises an elongate shaft 22 having at least one auger 40 extending therearound and a plate 50 rotatably supported at a fixed location therealong. The apparatus 20 is operable to be rotated by a piece of equipment 8, such as, by way of non-limiting example, an excavator, skid steer loader or crane such that the augers 40 and 42 draw the apparatus into the soil formation 10 as will be more fully described below.

[0028]The shaft 22 extends between bottom and top ends, 24 and 26, respectively and may have a length of between 12 to 20 feet (3658 and 6096 mm) although it will be appreciated that other lengths may be useful as well. As illustrated, the bottom end 24 of the shaft may be sharpened to ease insertion into a soil formation and the top end may have a plurality of transverse bores 28 thereth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com