Pressure relief device for swimming pools

a technology for swimming pools and pressure relief devices, which is applied in the direction of gyms, buildings, construction, etc., can solve the problems of swimming pool being destroyed, difficult to get it to go back to its original location, and the pool to be lifted out of the ground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

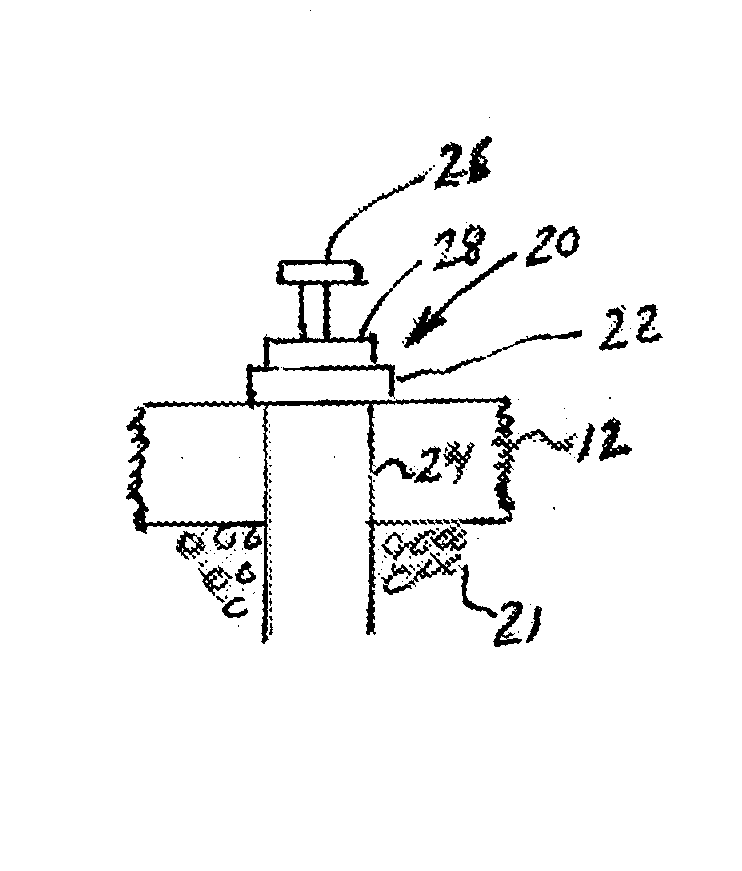

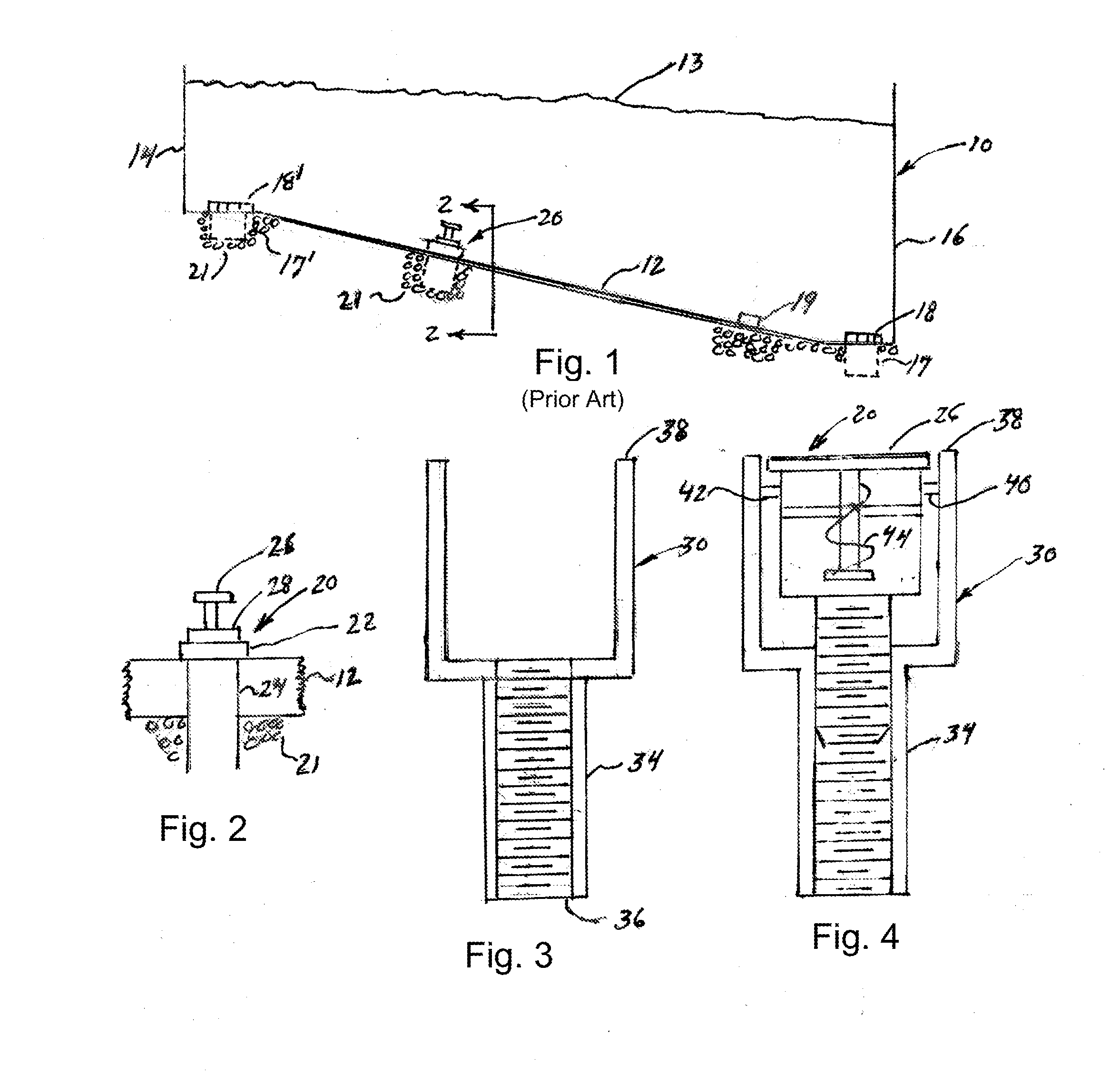

[0008]Referring to FIG. 1, a swimming pool 10 having a sloping bottom 12 is generally filled to a level shown by line 13. Conventional in-ground swimming pools made of poured or gunned concrete generally have a shallow end 14 and a deep end 16. In a conventional concrete pool the deep end 16 bottom contains a conventional water return fixture 17 for collecting pool water for recirculation through a water filtration system. Likewise, the shallow end 14 also contains an identical water return fixture 17′. Water return fixtures 17, 17′ are fitted with safety covers 18, 18′ as is well known in pool construction and user safety. The bottoms of fixtures 18,18′ are generally fitted with plugs (not shown) that can be removed when the pool is empty periodically for cleaning or painting. Removal of the plugs allows water accumulating under the pool to enter the pool for removal, thus preventing water pressure from building up under the pool.

[0009]In addition to pressure relief plugs in fixtur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com