Air exhaust outsole for safety footwear

a technology for air exhaust and safety footwear, applied in footwear, applications, clothing, etc., can solve the problems of affecting the air circulation of workers, affecting the comfort of workers,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

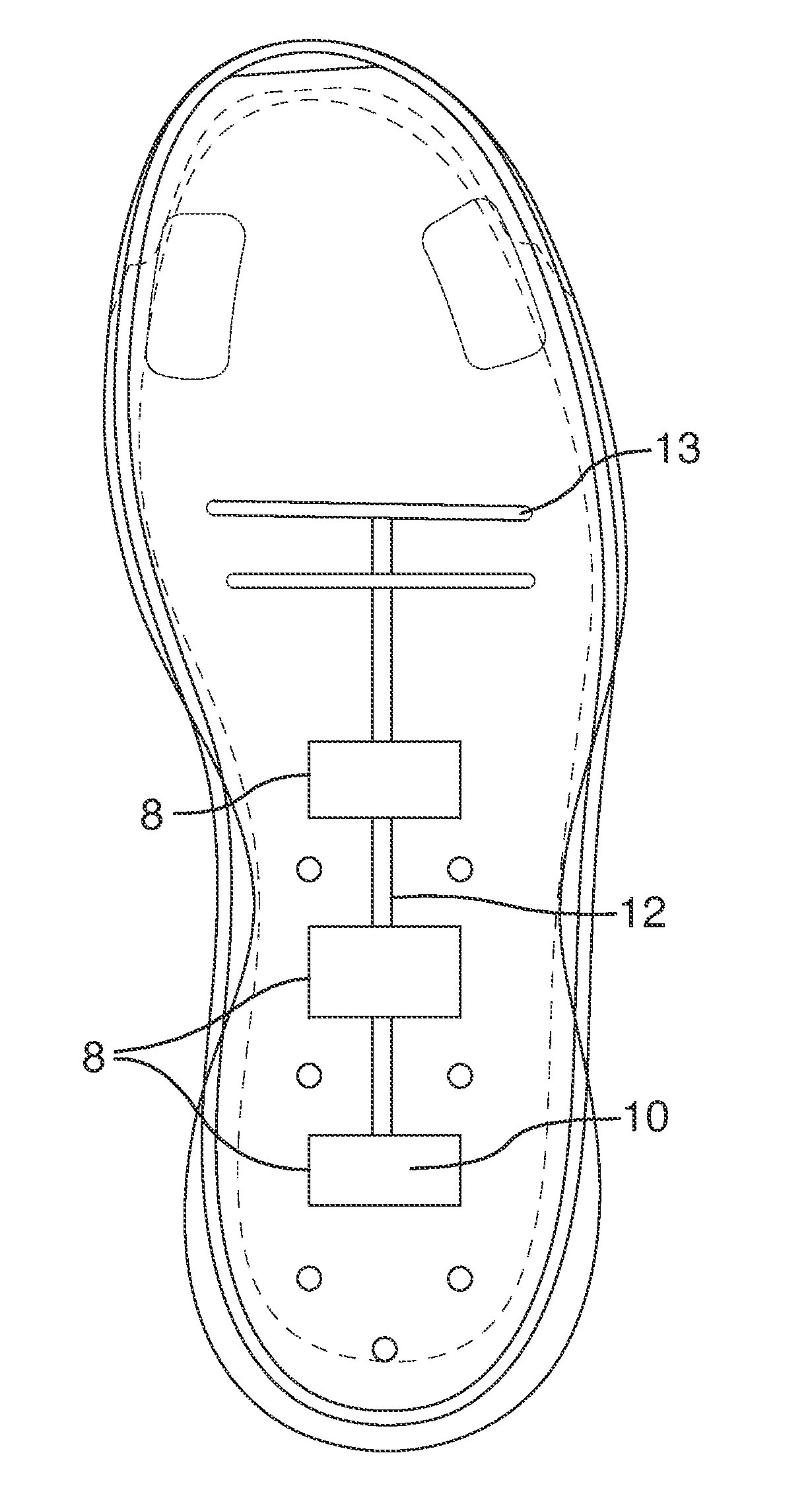

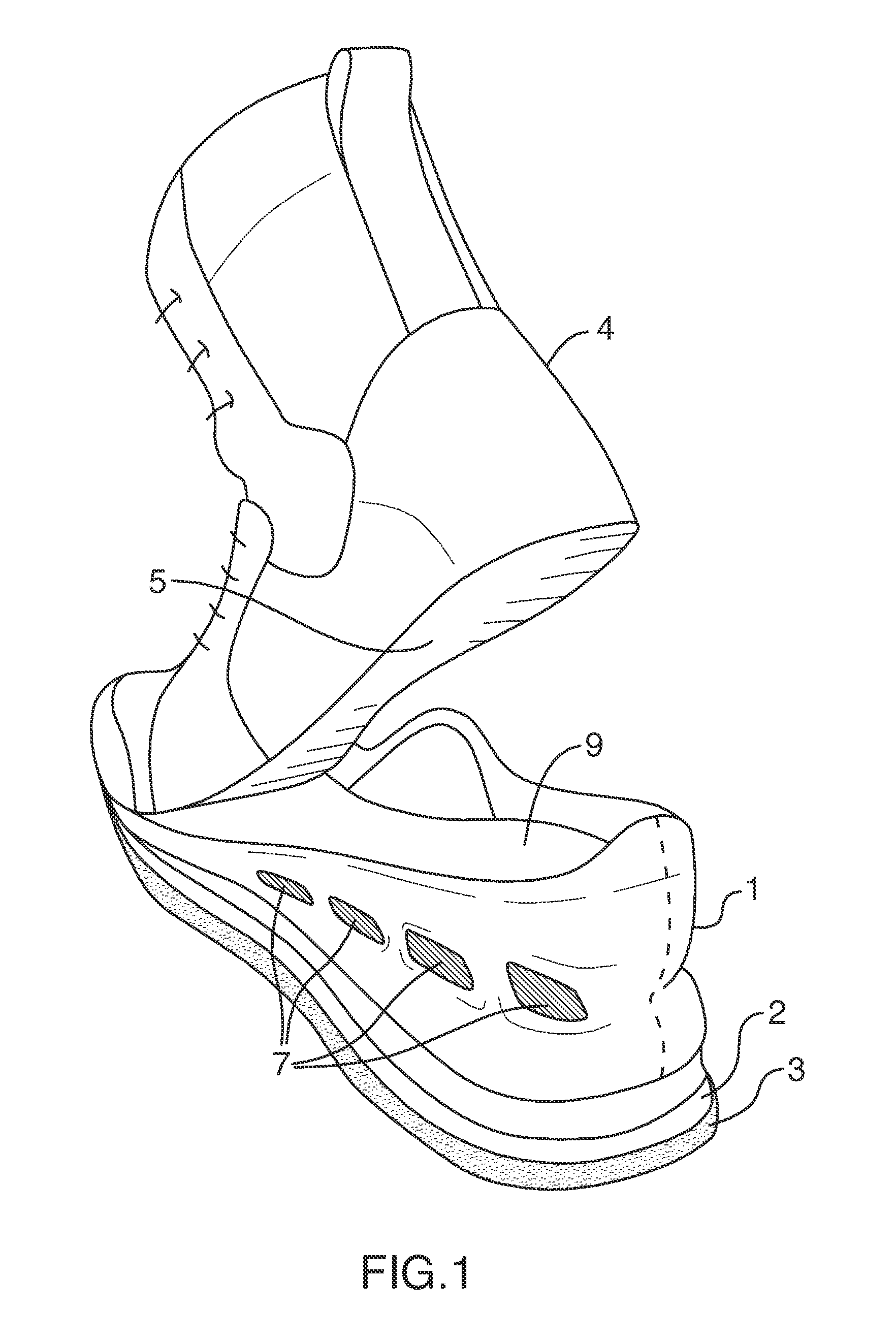

[0024]FIG. 1 shows an air exhaust outsole made of three layered components, namely, the air ventilating midsole 1, the puncture resistant layer 2 and the tread layer 3. The puncture resistant layer 2 is located away from the wearer's foot to enhance comfort since the midsole 1 can provide air ventilation and cushioning between the foot and puncture resistant layer 2 as described in detail below. The safety footwear includes an upper 4 with an air permeable insole 5 having a top insole surface for supporting a foot of the wearer.

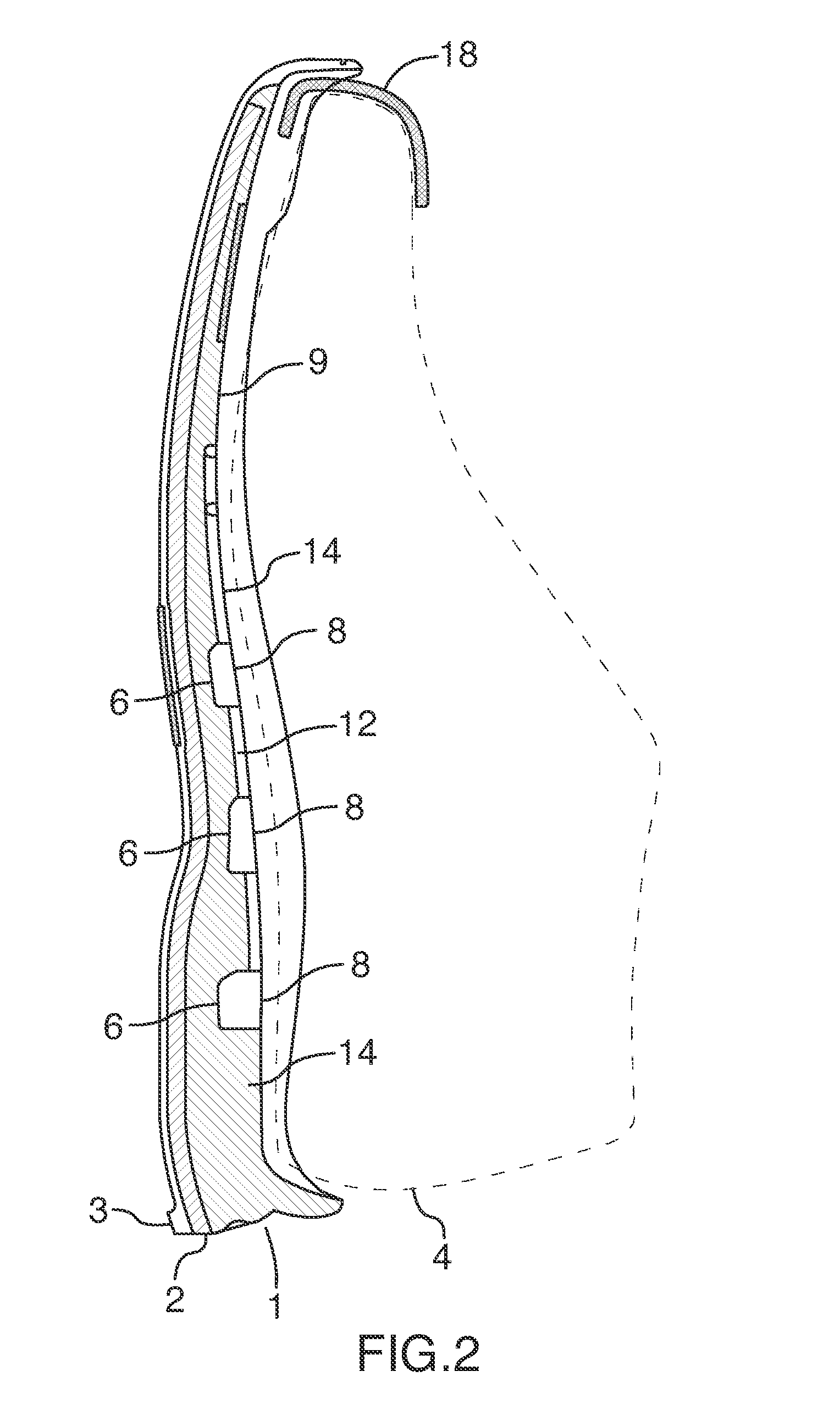

[0025]As seen in FIGS. 1, 2-3, the midsole 1 has a top midsole surface engaging the bottom insole surface 5 of the upper 4. In the longitudinal sectional view of FIG. 2 and transverse sectional views of FIGS. 6, 7 and 8 it can be seen that the midsole 1 has four transverse ventilation channels 6 that extend between outlet ports 7 in a side midsole surface and inlet ports 8 in the top midsole surface 9.

[0026]Therefore each of the four longitudinally spaced apa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com