Electrical Wire Spooling and Dispensing Device

a technology for electric wires and spools, which is applied in the direction of transportation and packaging, thin material processing, filament handling, etc., can solve the problems of tangles and crinkles in the wires, and achieve the effects of preventing over-dispensing, preventing over-dispensing of wires, and quick and easy removal and replacemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Electrical Wire Dispensing

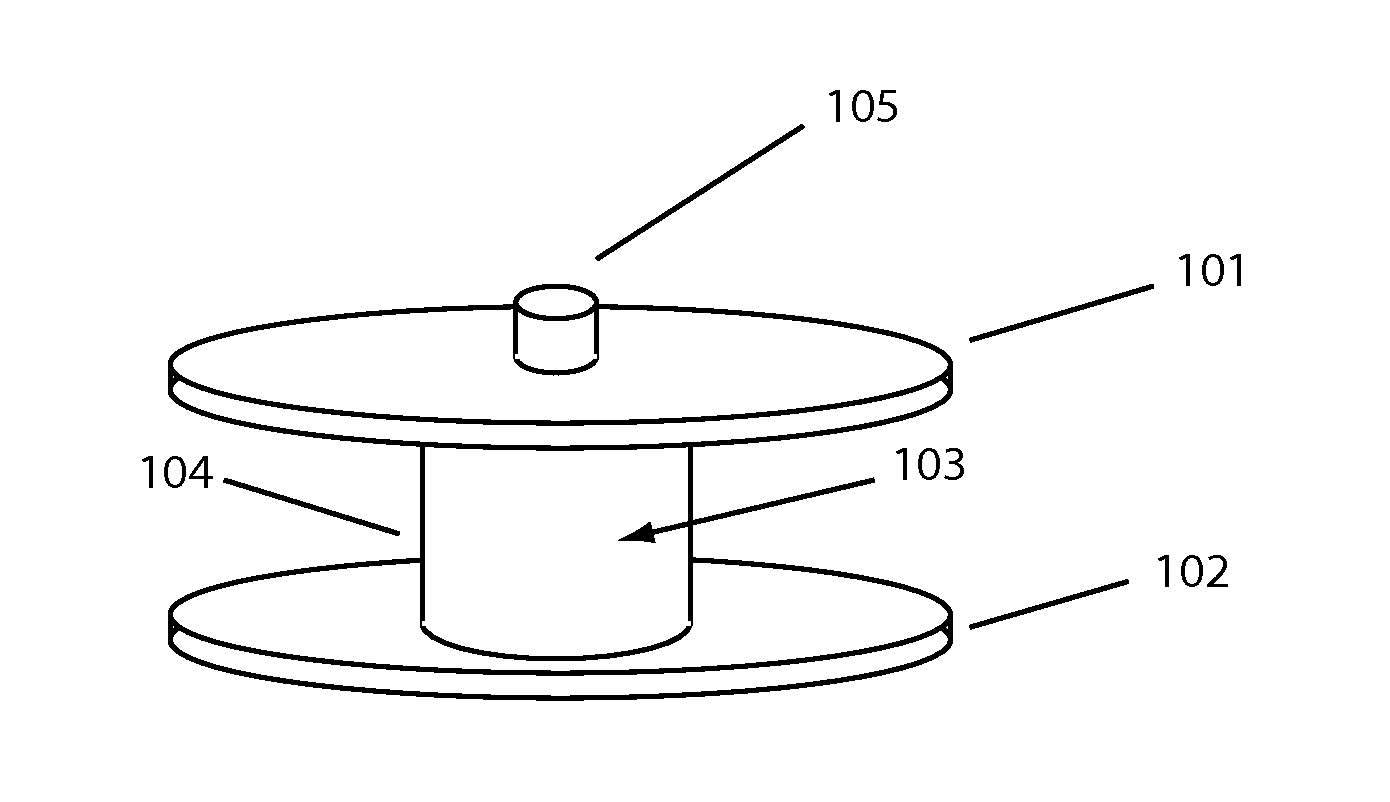

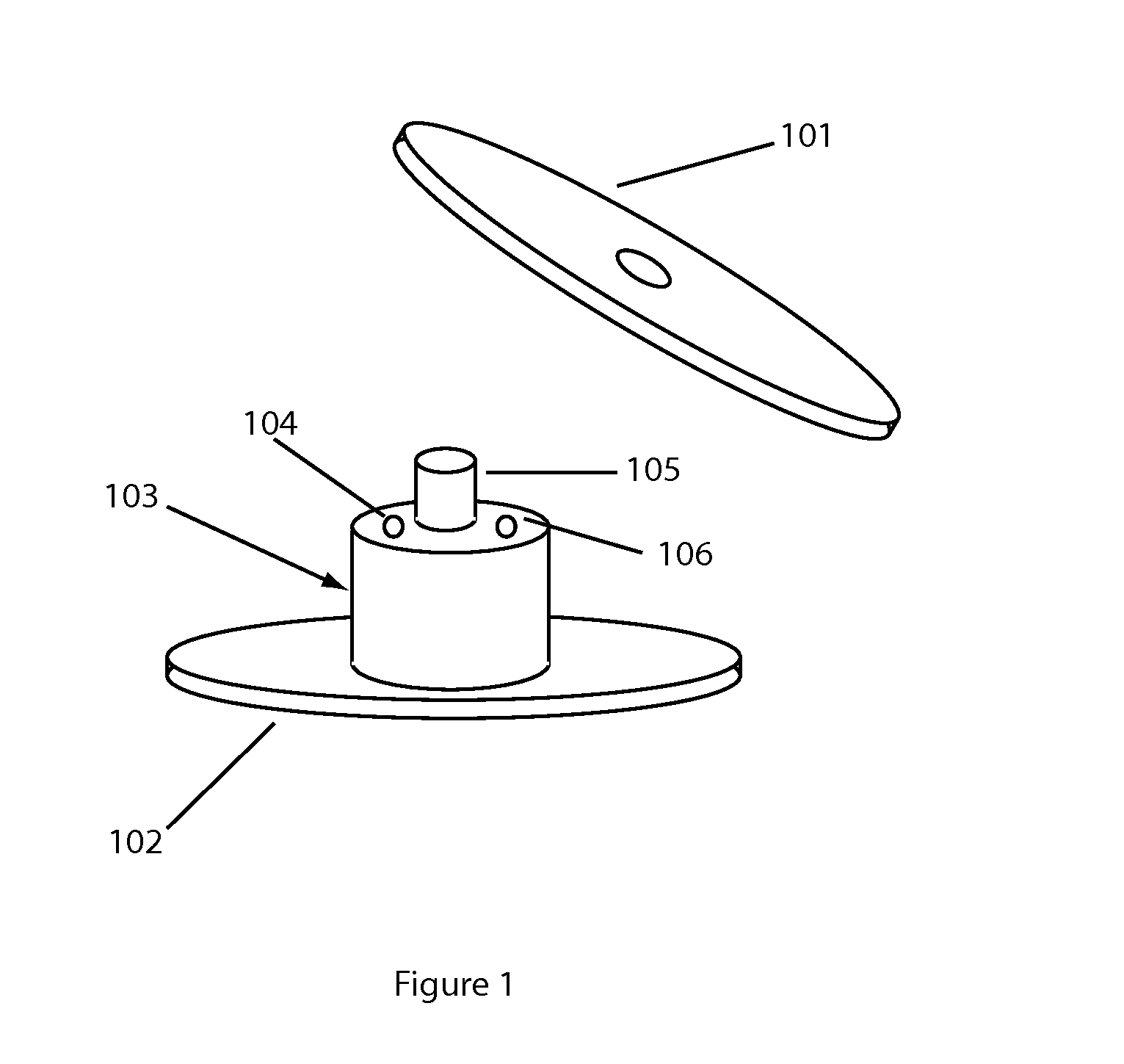

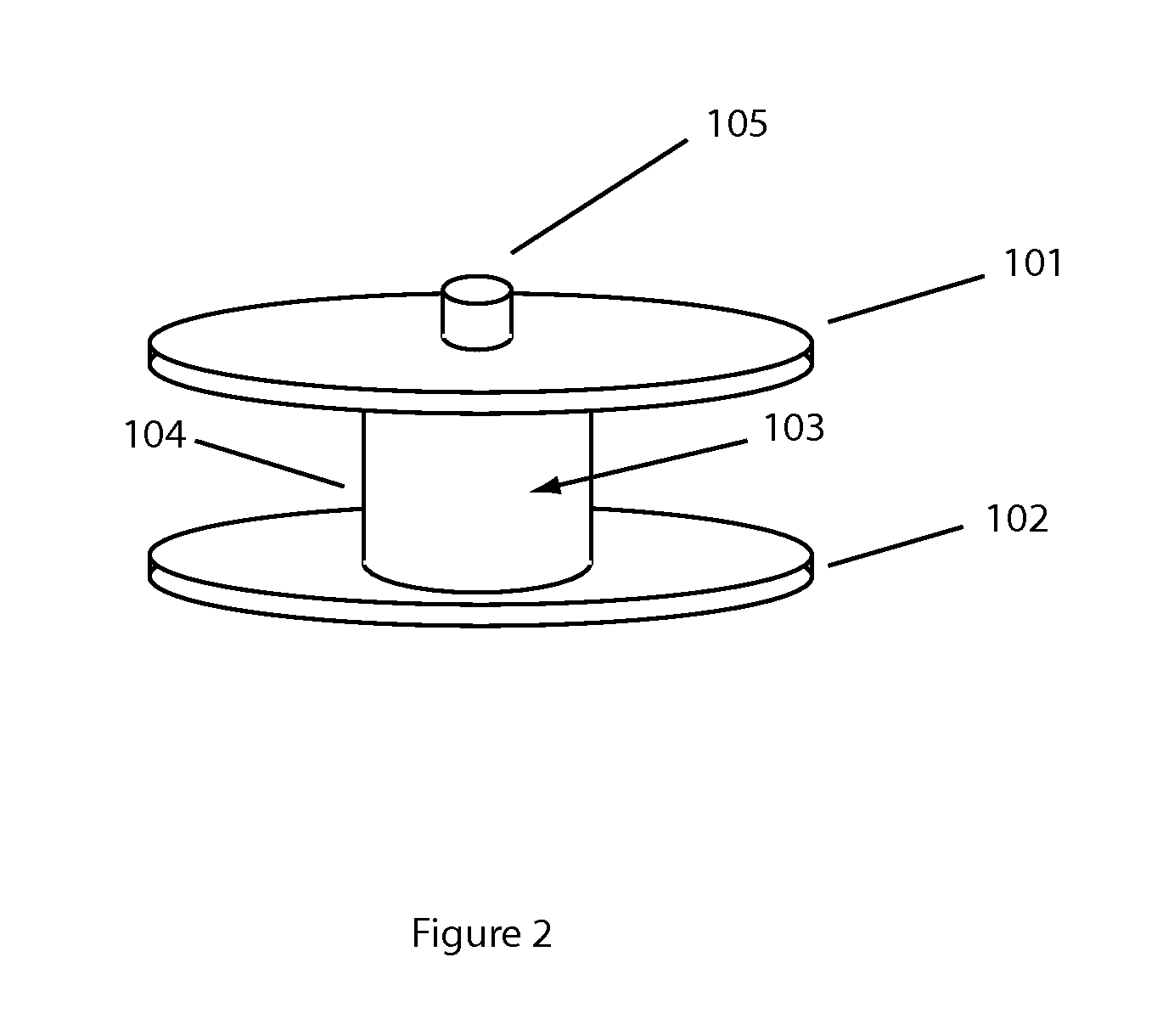

[0030]The present invention may, in a preferred embodiment, be deployed to be loaded with and dispense electrical wire, such as is used for construction and other purposes.

[0031]In such uses, electrical wire commonly sold in small coils may be easily loaded onto the device by removing either the upper or lower side wall. Once the coil is placed around the device cylinder, the packaging of the coil may be removed if desired. The previously removed side wall of the device may then be replaced. The user may then pull the end of the coiled wire slowly to dispense as needed.

[0032]The presently described device is small enough to be carried as needed by the electrician or other user around the job site. Further, the device is capable of being loaded with smaller coils of wire, allowing the user to select the appropriate size coil for the job at hand. This prevents the user from having to carry wire in great excess of what is needed for a particular job, resulting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com