Spindle motor and disk drive apparatus

a technology of spindle motor and disk drive, which is applied in the direction of windings, instruments, record information storage, etc., can solve the problems of lead wire breaking, wire damage, and unwanted biting of passage lines, so as to minimize the passage lines of conducting wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

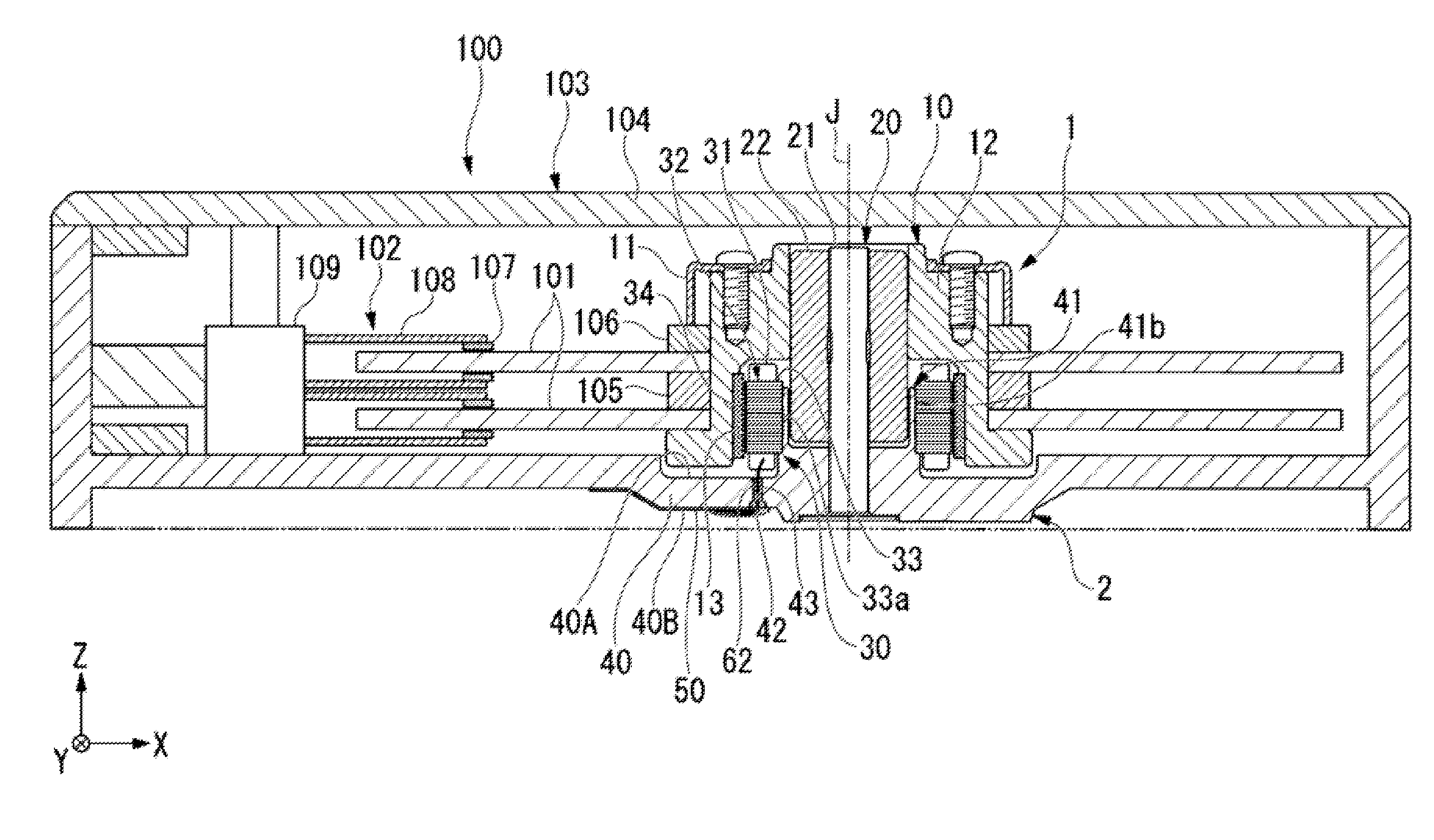

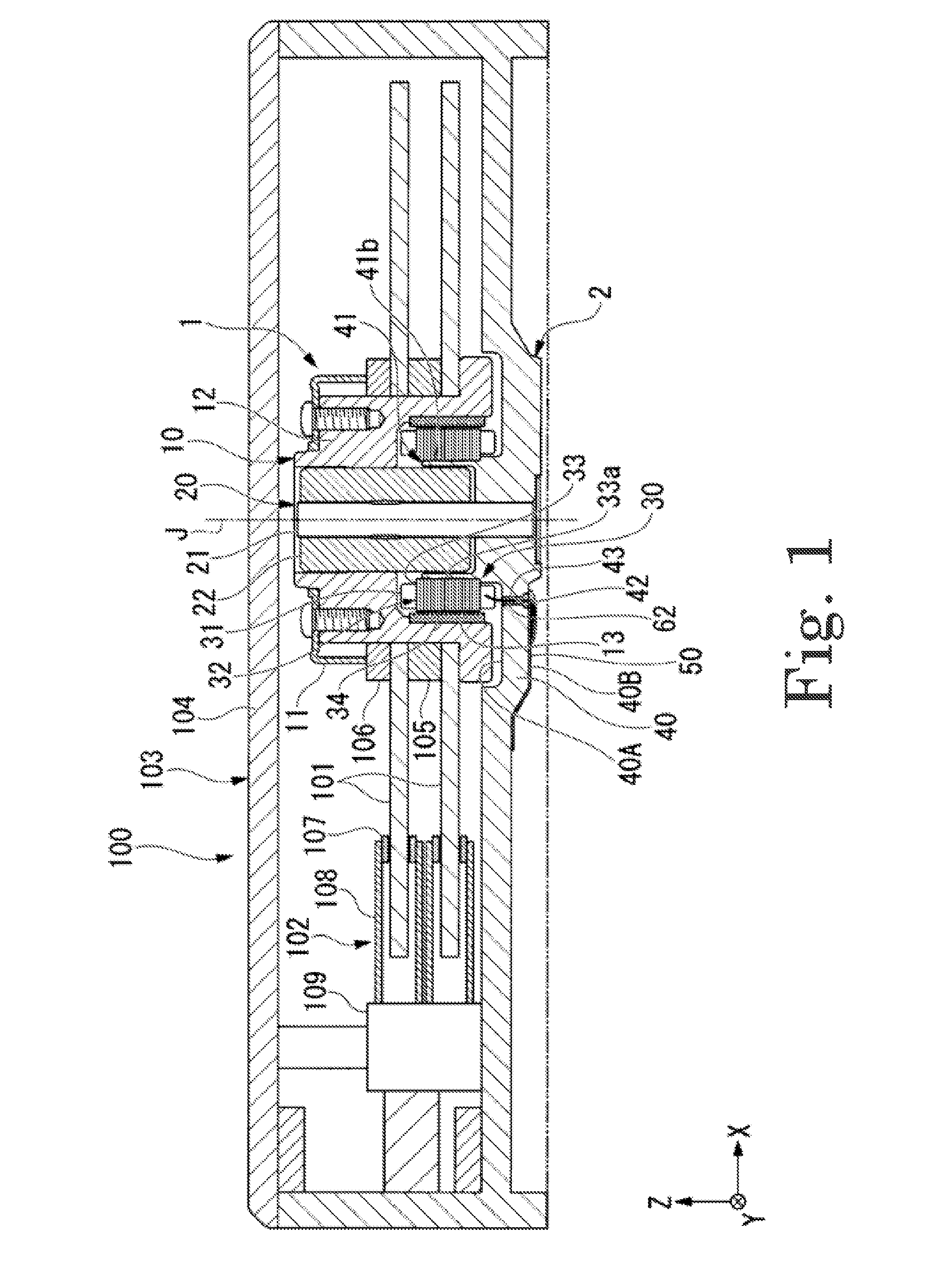

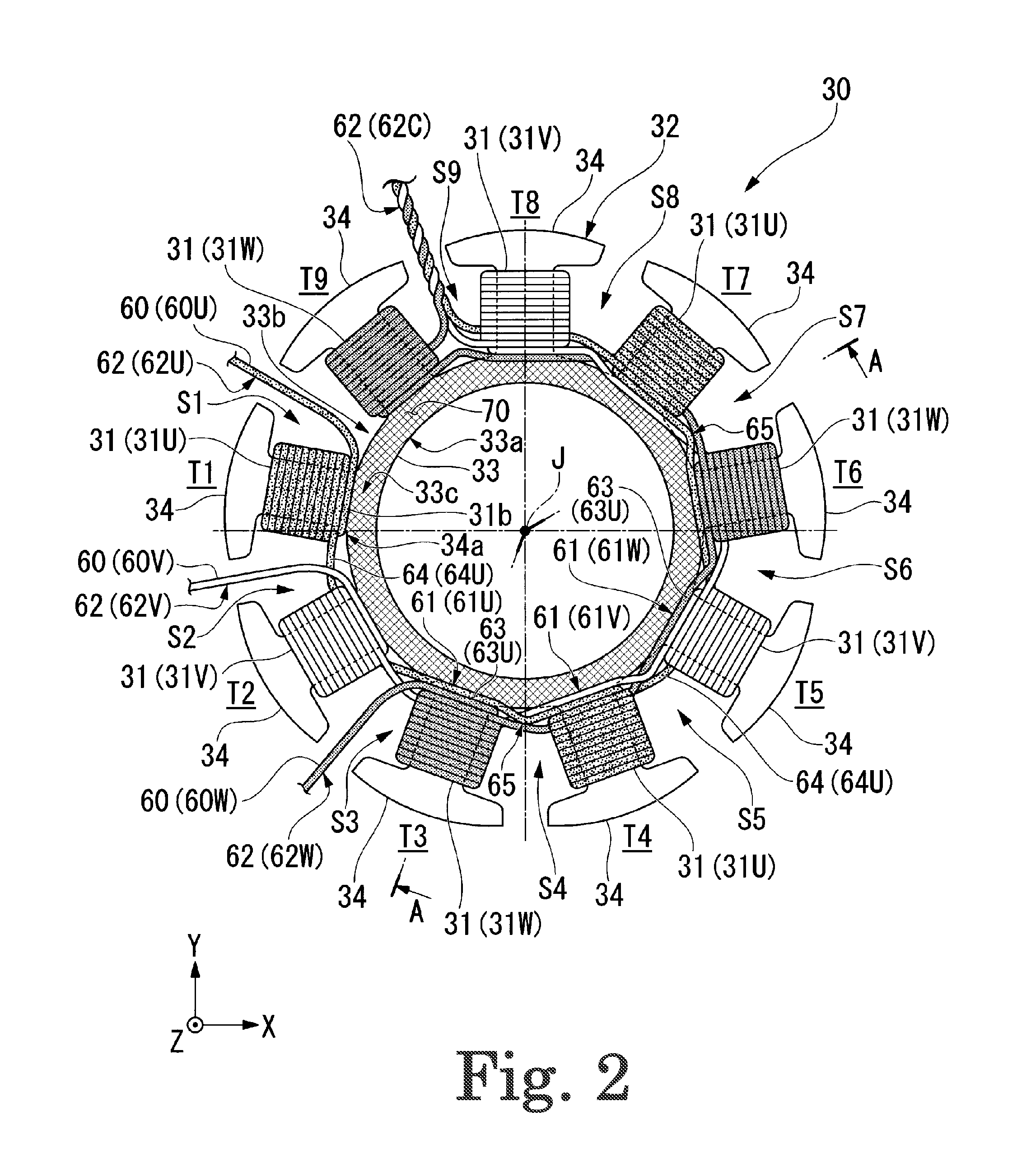

[0017]Hereinafter, preferred embodiments of the present invention will be described with reference to the accompanying drawings. Note that the scope of the present invention is not limited to the preferred embodiments described below, but includes any modification thereof within the scope of the technical idea of the present invention. Also note that scales, numbers, and so on of members or portions illustrated in the following drawings may differ from those of actual members or portions, for the sake of easier understanding of the members or portions.

[0018]In the following drawings, an xyz coordinate system is shown appropriately as a three-dimensional orthogonal coordinate system. In the xyz coordinate system, a z-axis direction is assumed to be a direction parallel to a central axis J extending in a vertical direction in FIG. 1. A y-axis direction is assumed to be a direction perpendicular to a z-axis. An x-axis direction is assumed to be a direction perpendicular to both the z-a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| conducting | aaaaa | aaaaa |

| surface | aaaaa | aaaaa |

| insulating | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com