Pallet cap

a technology of pallet caps and covers, applied in the field of pallet caps or covers, can solve the problems of inability to store pallet caps themselves, high cost of pallet caps, and high cost of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

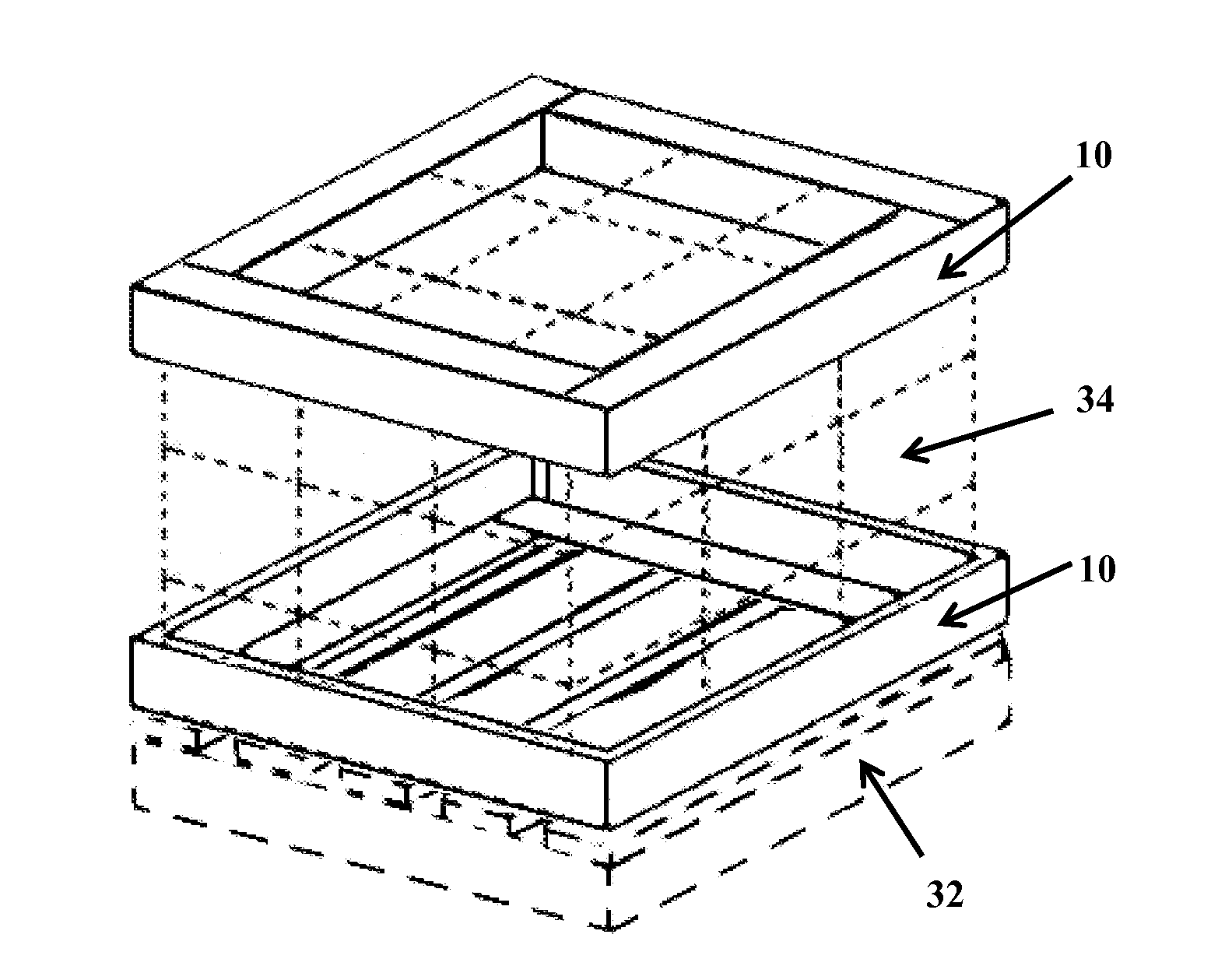

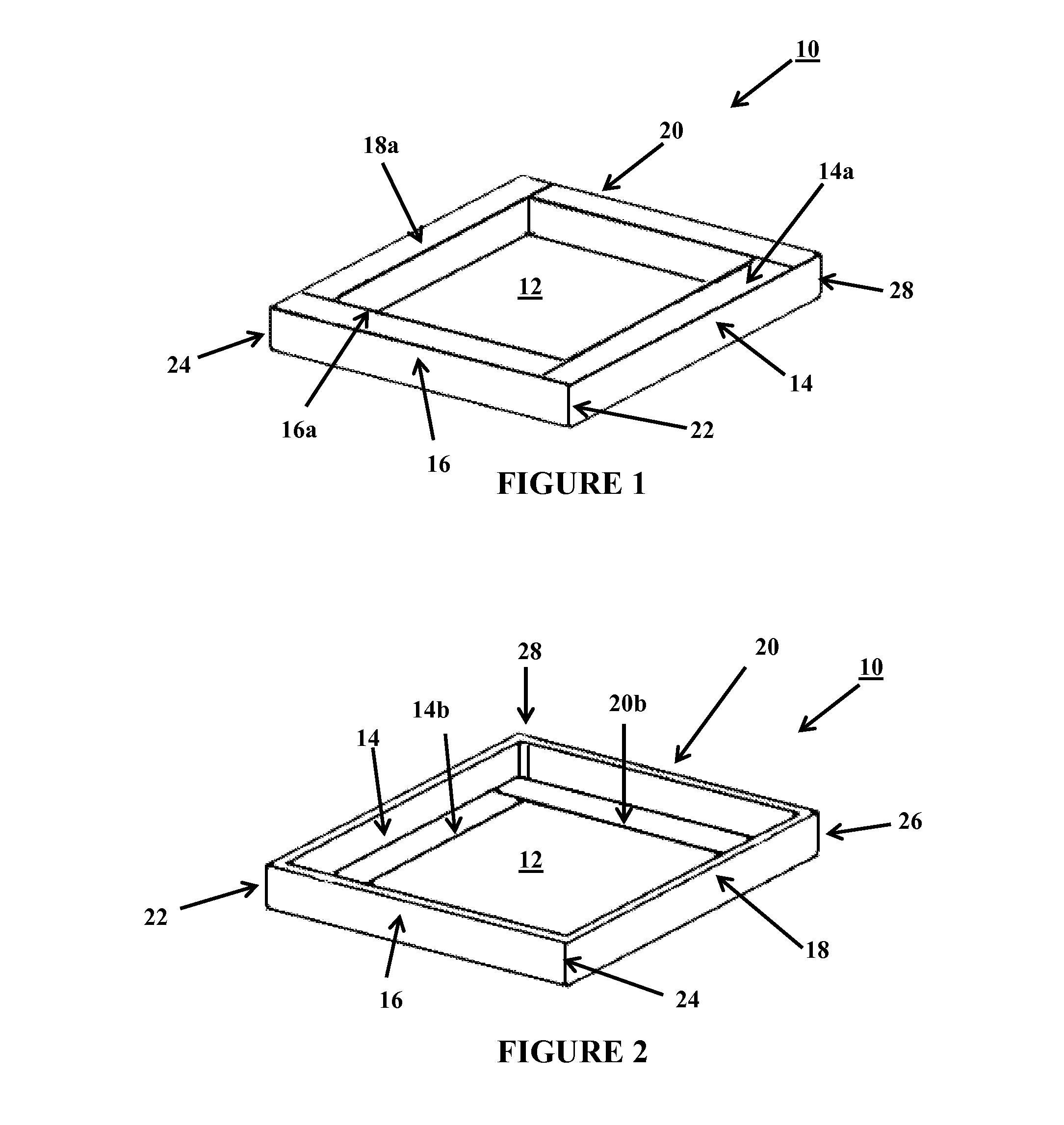

[0013]Referring now to FIGS. 1 and 2 there is shown a pallet cap 10 having a generally rectangular shape comprising four peripheral extending flange portions 14, 16, 18 and 20 and four top rim portions 14a, 16a, 18a and 20a which are integrally defined by flange corners 22, 24, 26 and 28. Furthermore, the four top rim portions 14a, 16a, 18a and 20a of pallet cap 20 also defines interior step portions 14b, 16b, 18b and 20b wherein the top rim and associated step portions, respectively further define a cutout center portion 12. The pallet cap 10 is preferably constructed of a soft flexible material, such as paperboard, cardboard or the like.

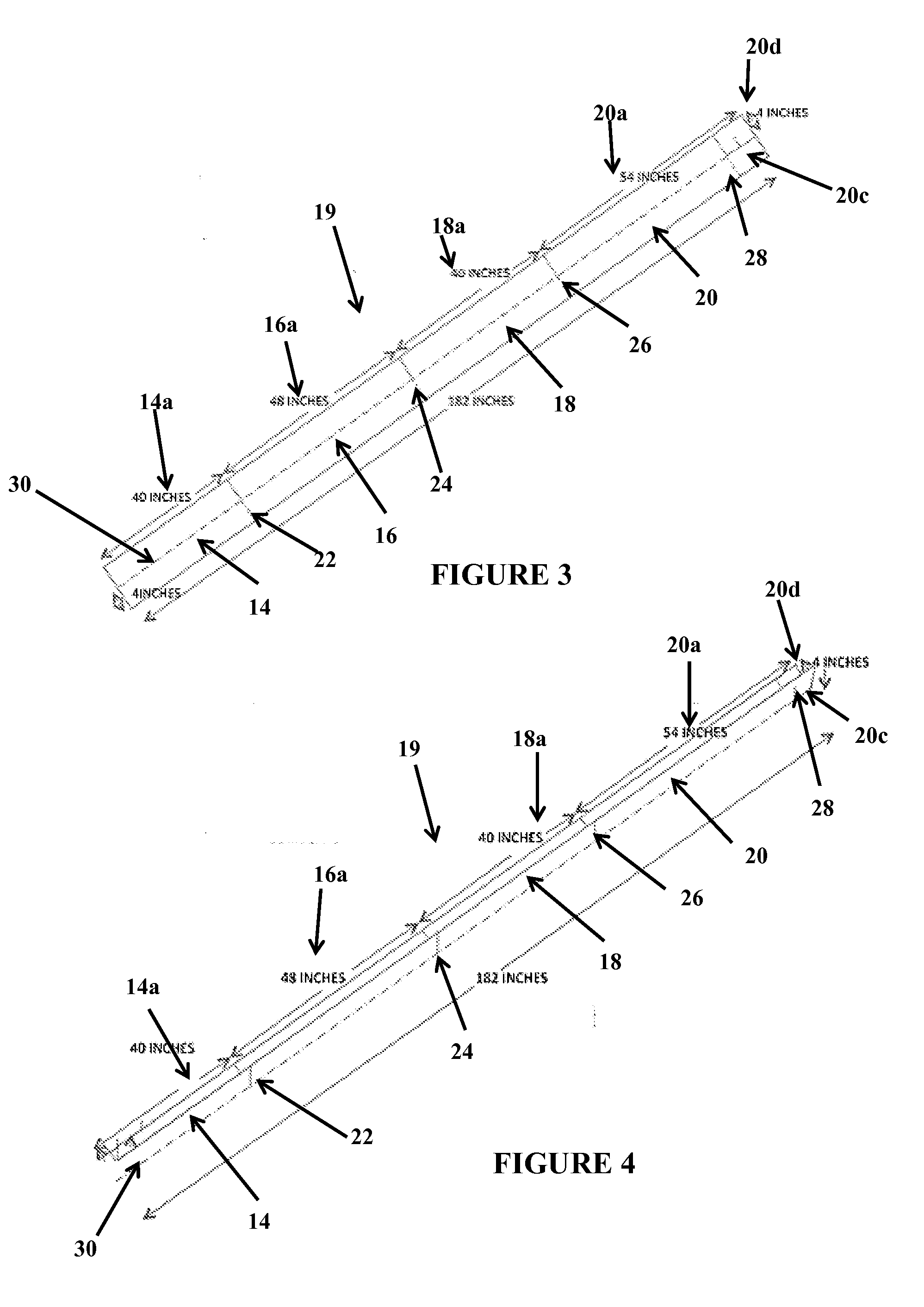

[0014]Referring now to FIGS. 3 through 8, the pallet cap 10 is formed and assembled starting with a flat paperboard or cardboard strip 19 of a predetermined length and width which in a preferred embodiment is 182 inches in length and 8 inches in width. As shown in FIG. 3 the flat paperboard or cardboard strip 19 is longitudinally scored 30 down the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com