Electrical connector

a technology of electric connectors and connectors, applied in the direction of electrical apparatus, connection, coupling device connection, etc., can solve the problems of difficult to simplify the connection operation, reduce the amount of work as much as possible, and the moveable member becomes an obstacle, so as to facilitate the pulling out of the flat conductive member

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]Hereunder, an embodiment of the present invention will be described with reference to the accompanying drawings.

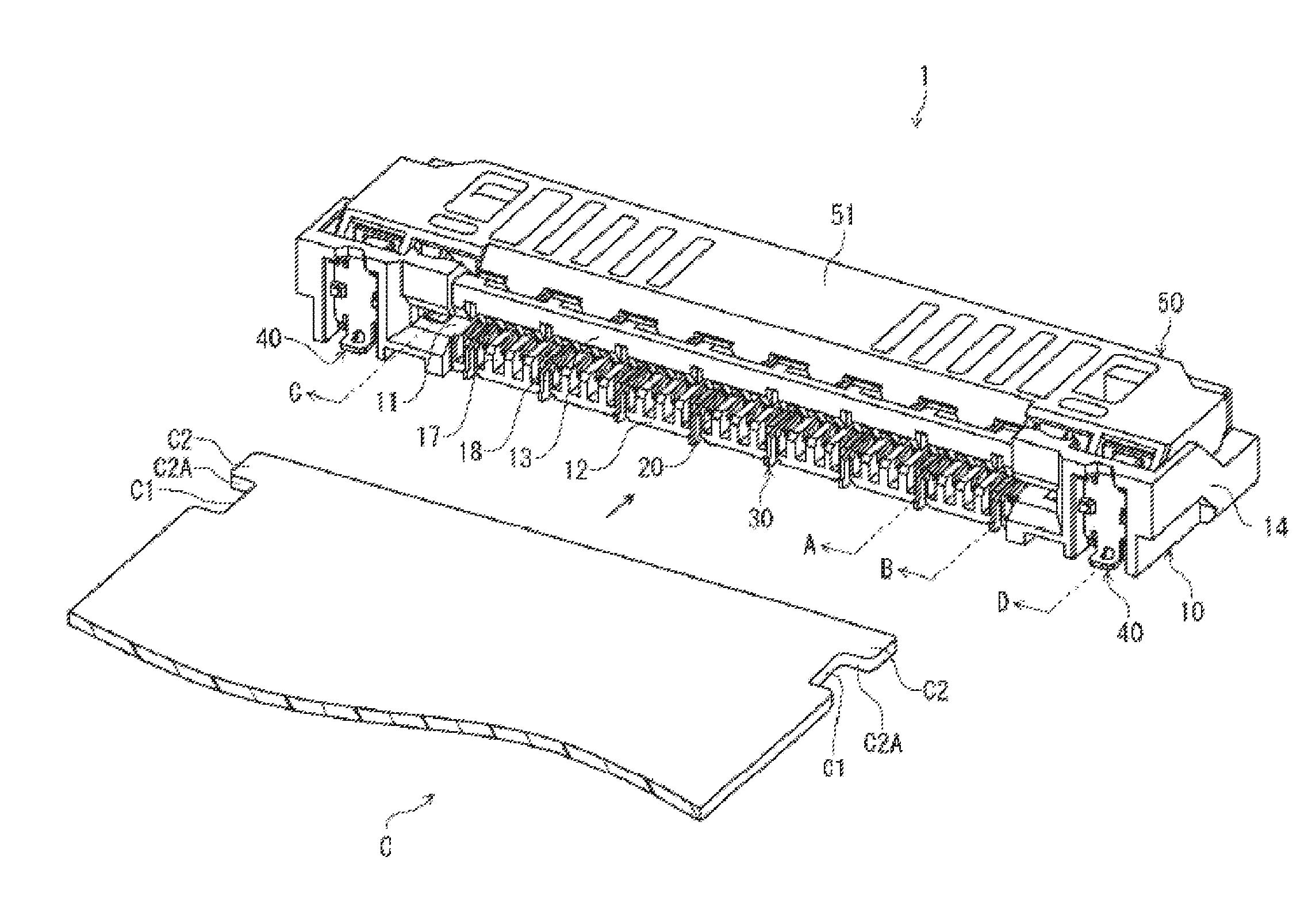

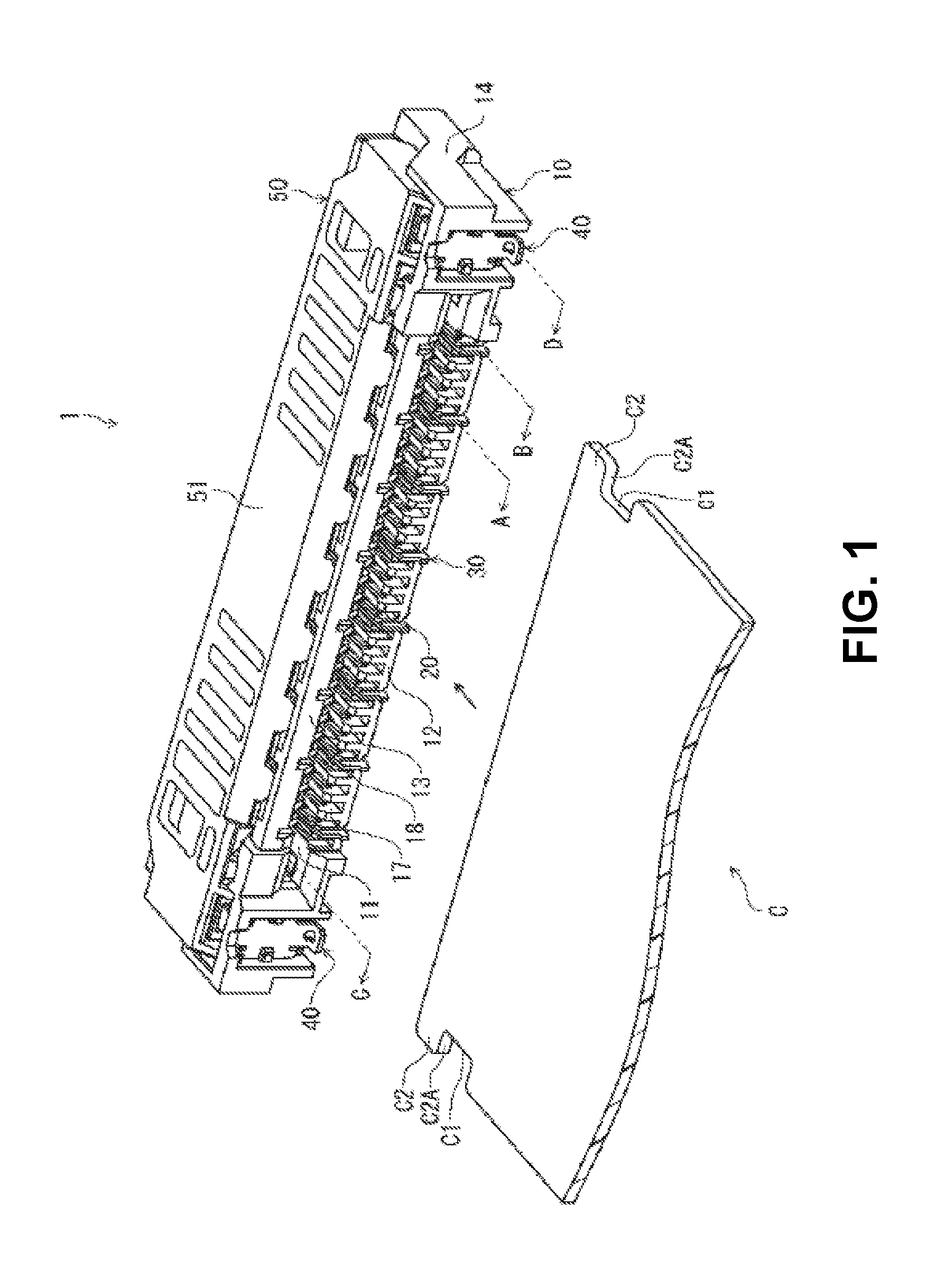

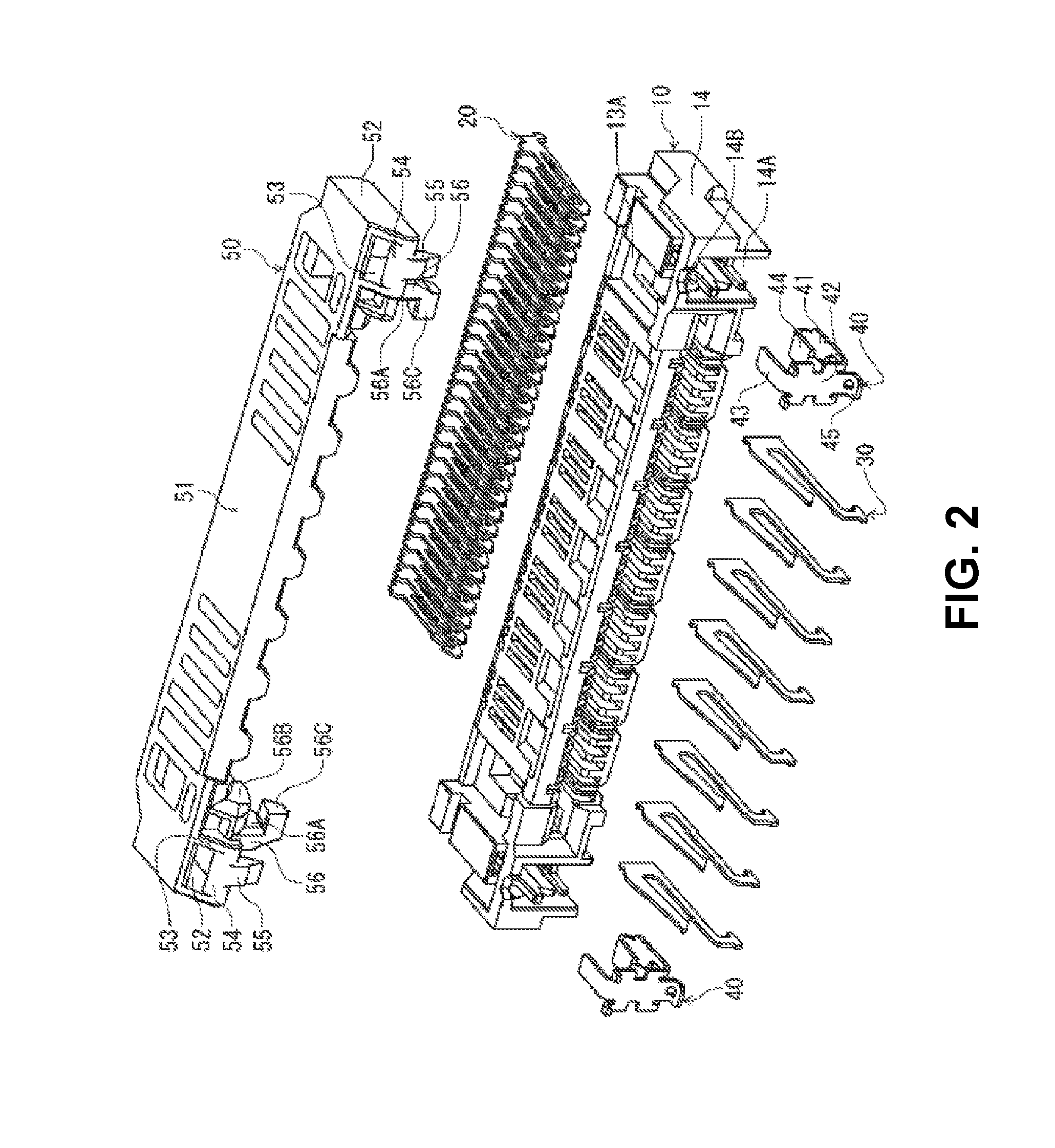

[0037]FIG. 1 is a perspective view showing an electrical connector 1 for a flat conductive member C (hereinafter, referred to as “connector 1”) and the flat conductive member C according to an embodiment of the present invention. FIG. 2 is an exploded view showing the connector 1.

[0038]FIGS. 3(A) through 3(D) are sectional views showing the electrical connector 1 before the flat conductive member C is inserted into the electrical connector 1 taken along a surface perpendicular to an arrangement direction of terminals of the electrical connector 1 according to the embodiment of the present invention. More specifically, FIG. 3(A) is a sectional view showing the electrical connector 1 taken at a signal terminal (along a line A in FIG. 1). FIG. 3(B) is a sectional view showing the electrical connector 1 taken at a ground terminal (along a line B in FIG. 1). FIG. 3(C) is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com