Acoustical flooring tile and method of manufacture

a technology of vinyl flooring and manufacturing methods, applied in the field of vinyl flooring, can solve the problems of limited acoustic properties of vinyl flooring, chemical incompatibility, and inability to provide the necessary long-term adhesion, and achieve the effect of reducing or eliminating discoloration of vinyl flooring, good long-term bonding, and good long-term adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

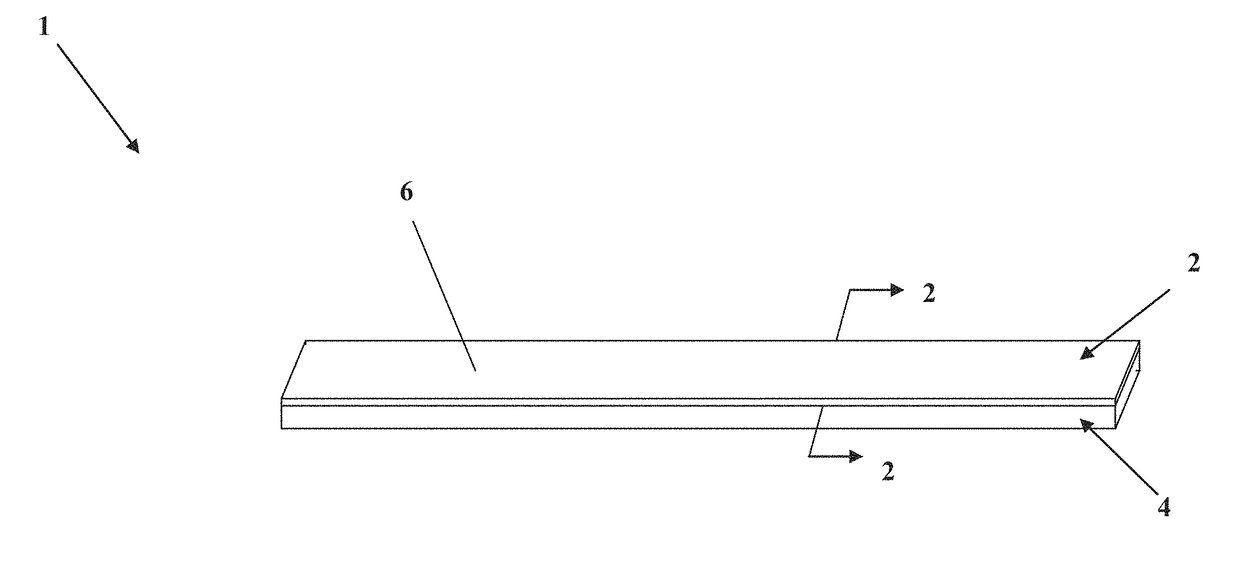

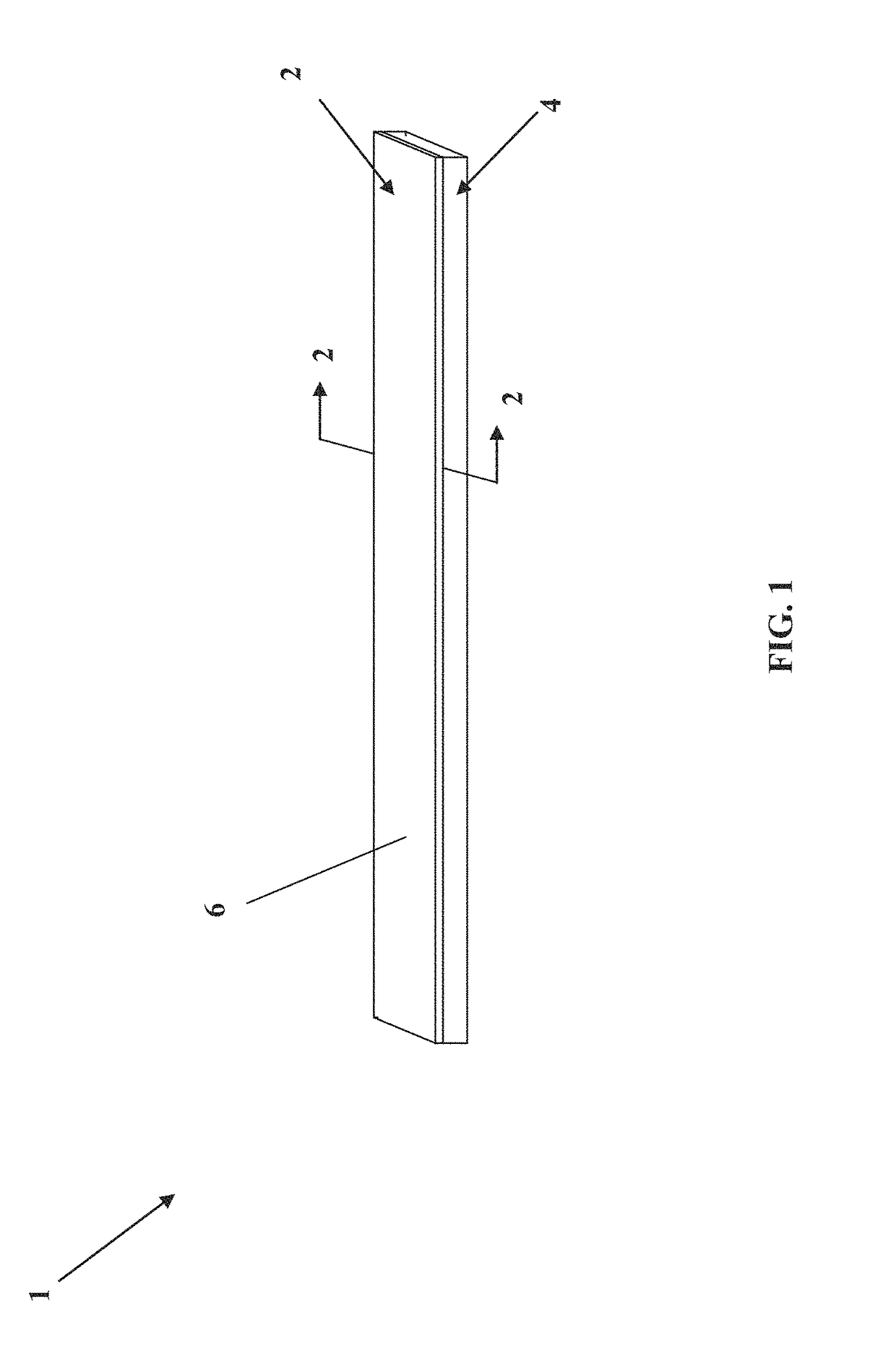

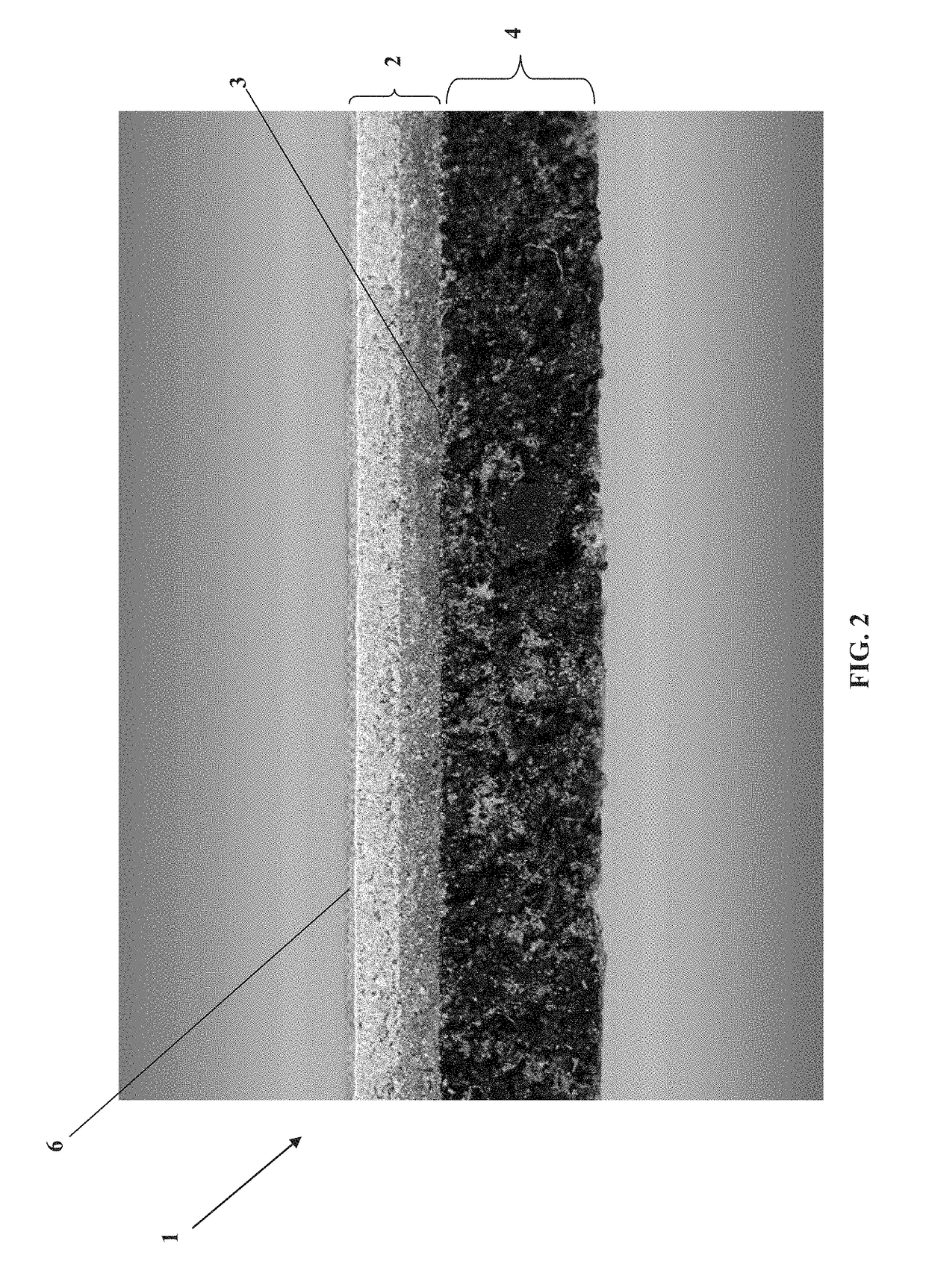

[0037]The disclosed vinyl tile comprises a vinyl layer with an integrated sound reducing underlayment permanently attached thereto. The resulting floor / ceiling assembly including the tile meets one or more of ASTM E 2179, ASTM E 989, ASTM E 492, and ASTM E1007 IIC sound requirements. The disclosed vinyl tile also eliminates the two-step installation process associated with prior vinyl tile flooring systems which require installing an underlayment to the subfloor using a first adhesive, then installing the vinyl tile over the underlayment using a second adhesive. The disclosed tile thus reduces the total time required for installation. Alternatively, the disclosed vinyl tile includes a customizable sound reducing underlayment (referred to as an “acoustical layer” or “acoustical portion”) that is selected for the particular sub-floor system that includes the floor / ceiling assembly design with this which the tile will be used. The disclosed tile thus provides a desired level of sound d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap