Golf club head cover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

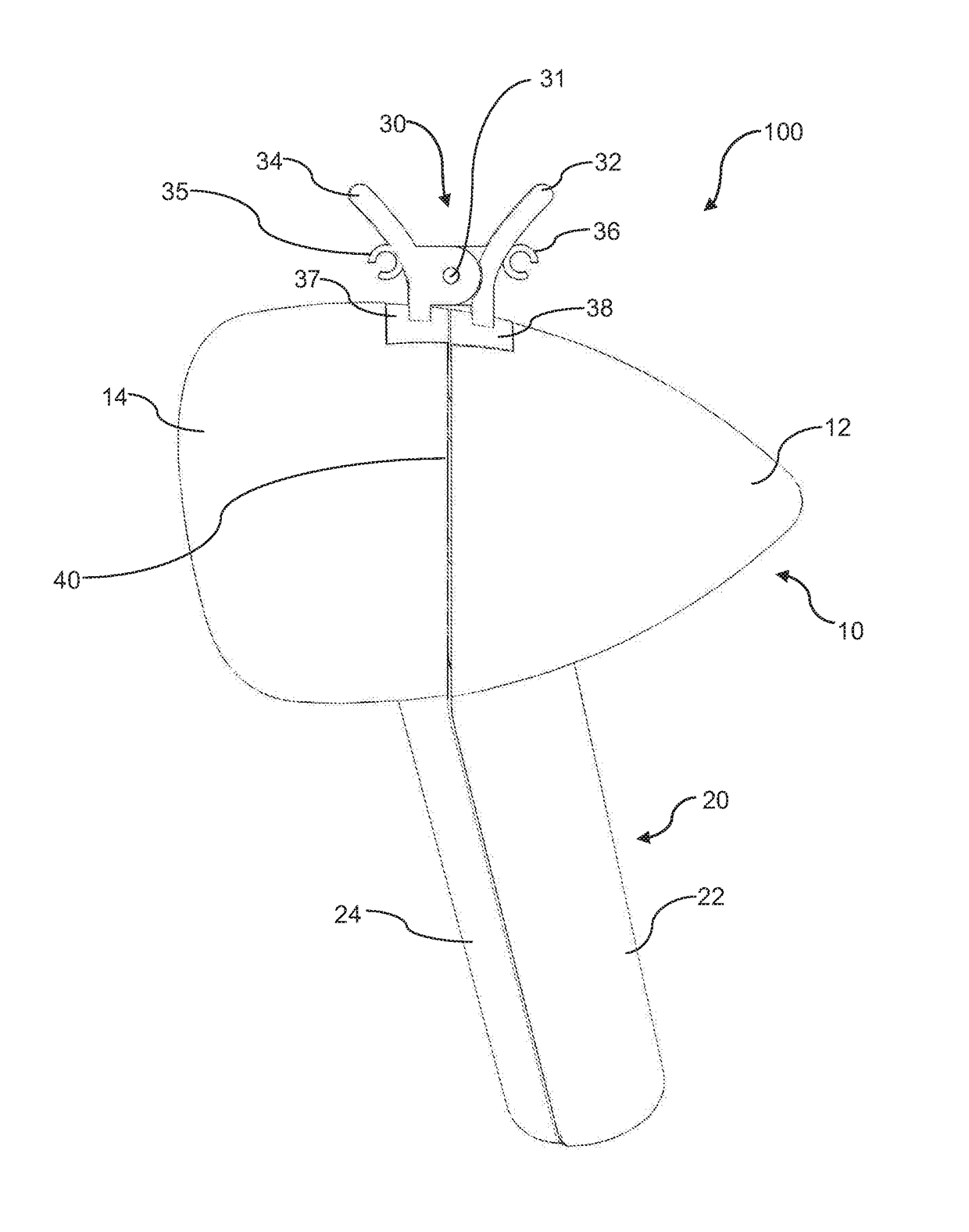

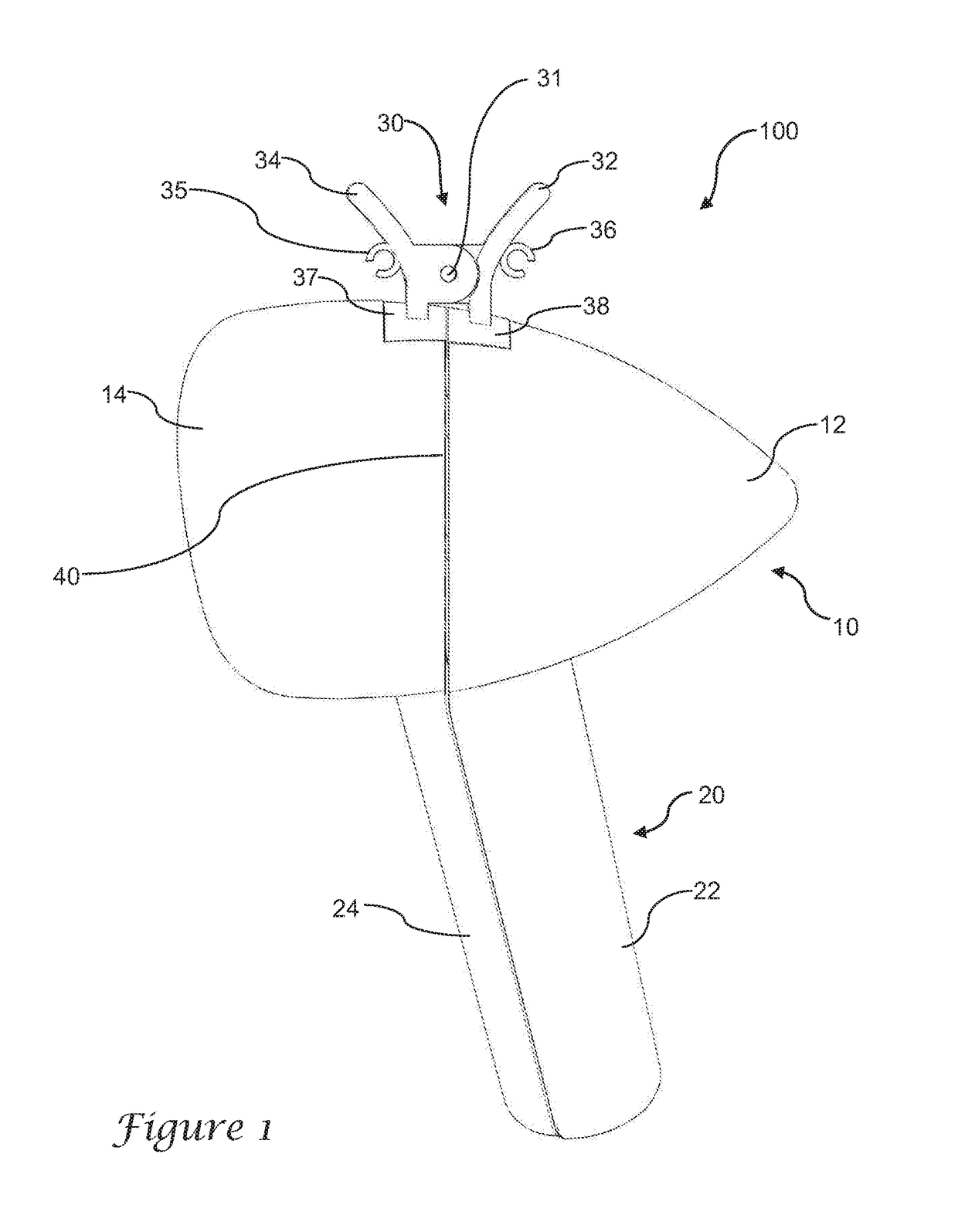

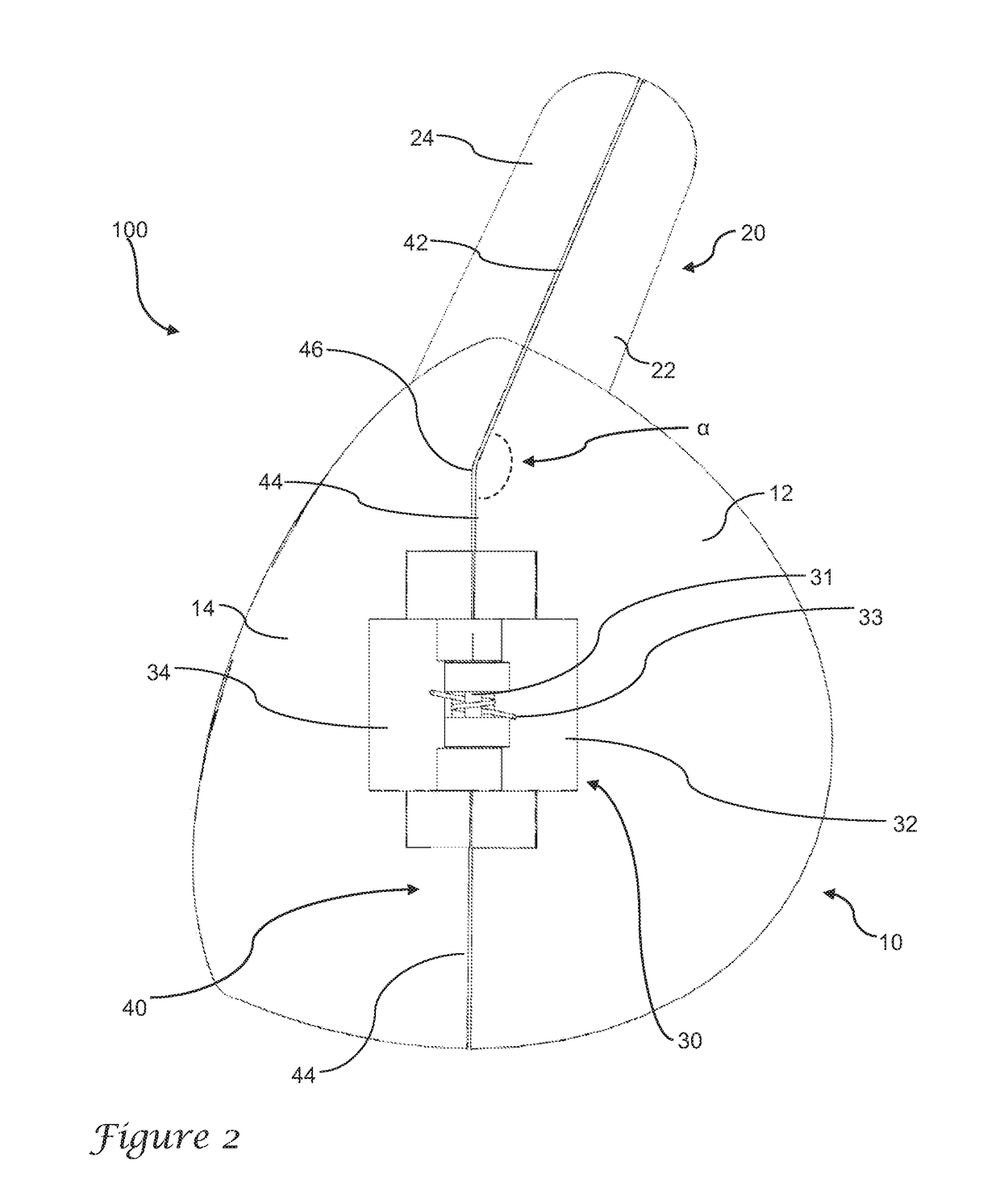

[0026]A preferred golf club head cover 100 is shown in a front view in FIG. 1. In a preferred version, the head cover 100 is formed with a clamshell configuration having a first half and a second half separated by a seam 40. The first half includes a first head covering portion 12 and a first shaft covering portion 22, and in the illustrated example the first head covering portion and the first shaft covering portion are integrally formed from a single material. In one version, each of the first half and the second half are formed from a castable flexible urethane foam. In other versions, it may be made from other more rigid plastic materials, or other resilient materials such as silicone. Most preferably, the particular version of foam is rated as a semi-rigid material such that it will not collapse under its own weight. The second half likewise includes a second head covering portion 14 and a second shaft covering portion 24, preferably integrally formed from a common material.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com