Grinding wheel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

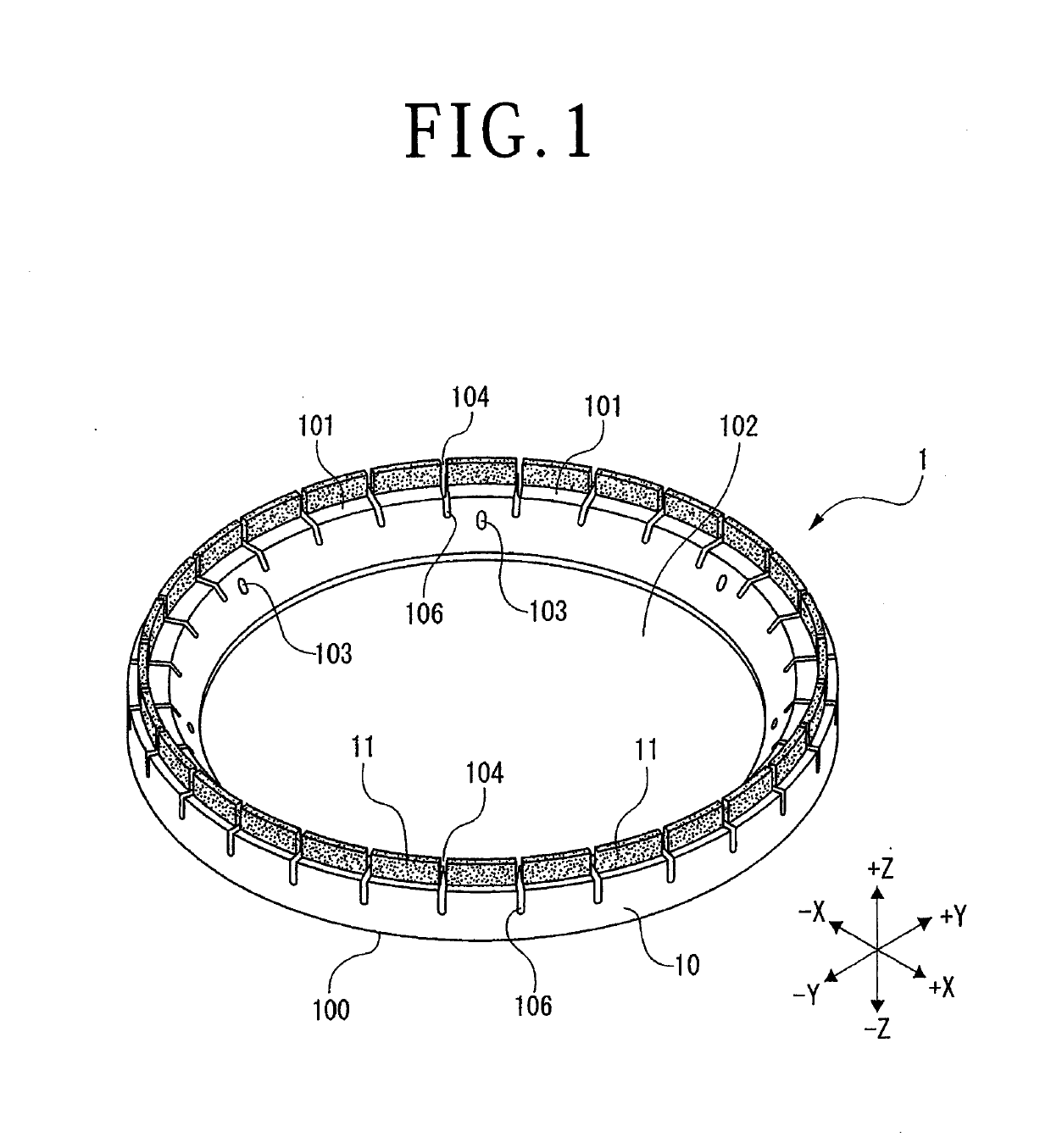

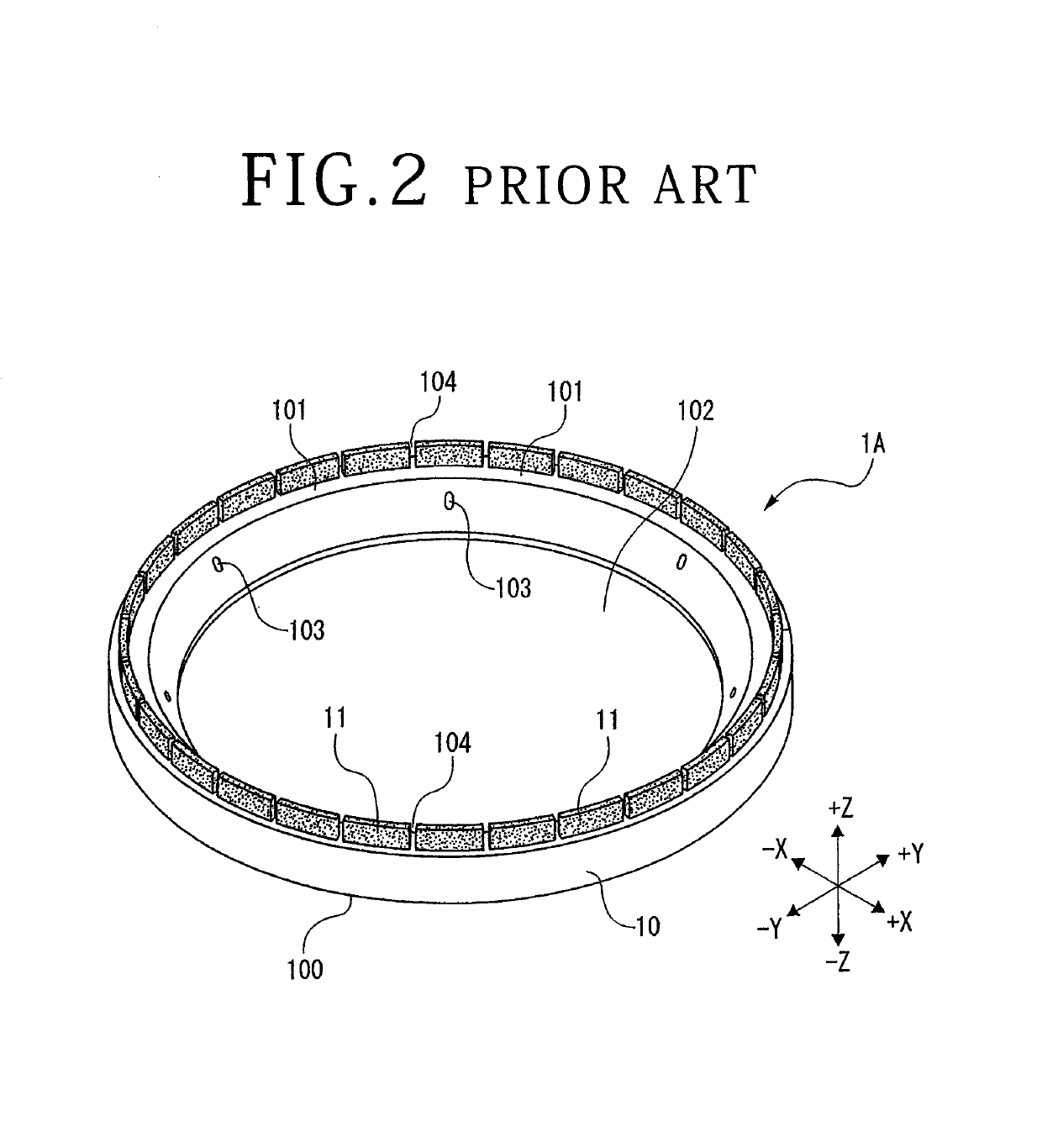

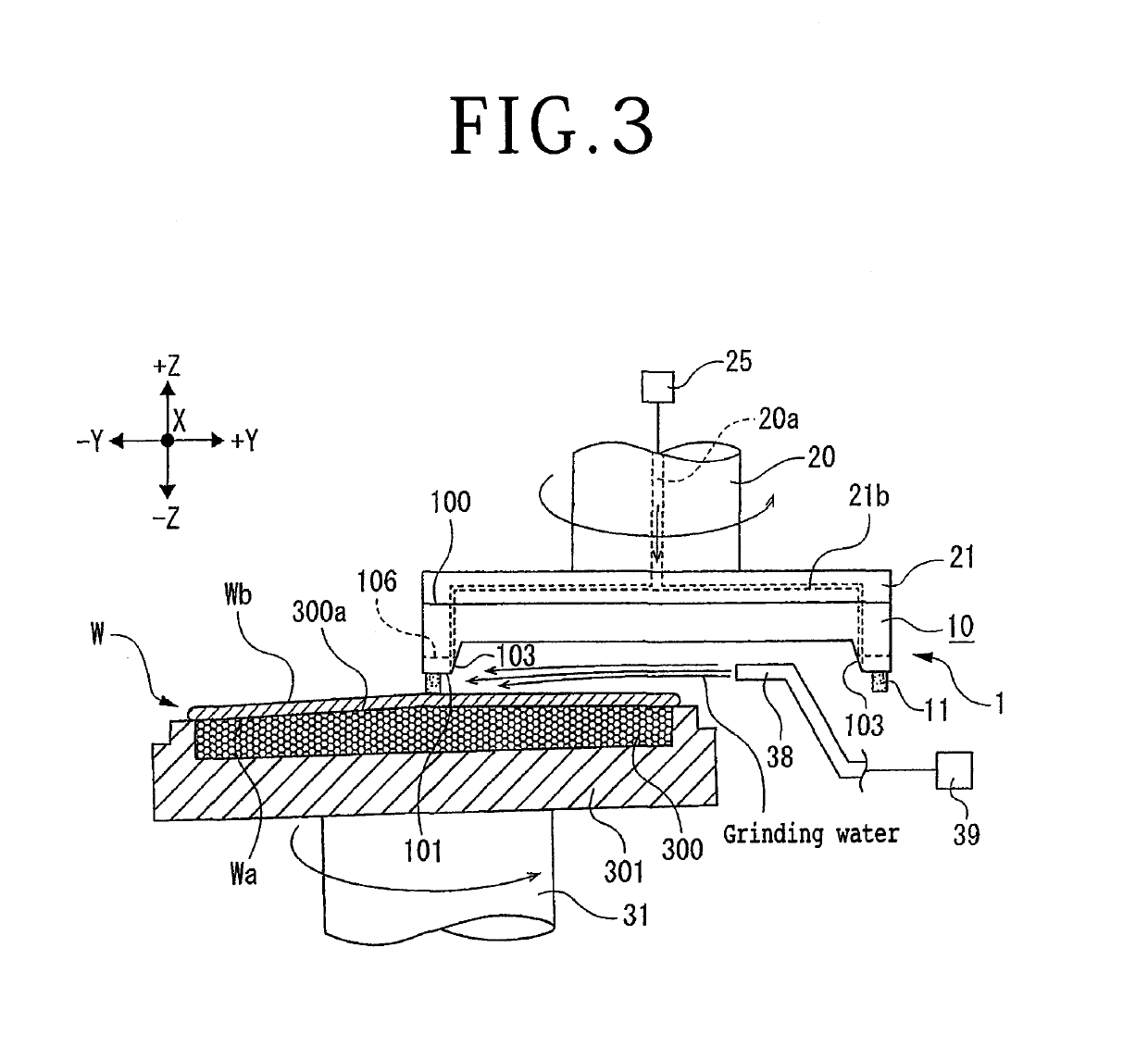

[0013]A grinding wheel 1 according to an embodiment of the present invention depicted in FIGS. 1 and 3 includes a ring-shaped base 10 formed of, for example, stainless steel or aluminum. The base 10 has a flat mounting surface 100. The mounting surface 100 is mounted on a side of a distal end of a spindle 20 depicted in FIG. 3 via a wheel mount 21 depicted in FIG. 3. A surface of the base 10 opposite to the mounting surface 100 assumes a flat grindstone fixing surface 101. A segment grindstone is fixed to the grindstone fixing surface 101. The mounting surface 100 and the grindstone fixing surface 101 extend in parallel with each other. As depicted in FIG. 1, the base 10 has a circular opening 102 formed at a center thereof. The opening 102 passes through the base 10, extending from the mounting surface 100 to the grindstone fixing surface 101.

[0014]A plurality of segment grindstones 11 are fixedly attached annularly to the grindstone fixing surface 101 of the base 10 by an appropri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com