Modular raised floor system with cable-receiving groove network

a technology of cable-receiving grooves and modules, applied in the field of raised floors, can solve the problems of difficult manufacture, installation, maintenance and cleaning of the same, and achieve the effect of improving the quality of the floor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

These and other features and advantages of this invention will become apparent in the following detailed description of a preferred embodiment of this invention, with reference to the accompanying drawings, in which:

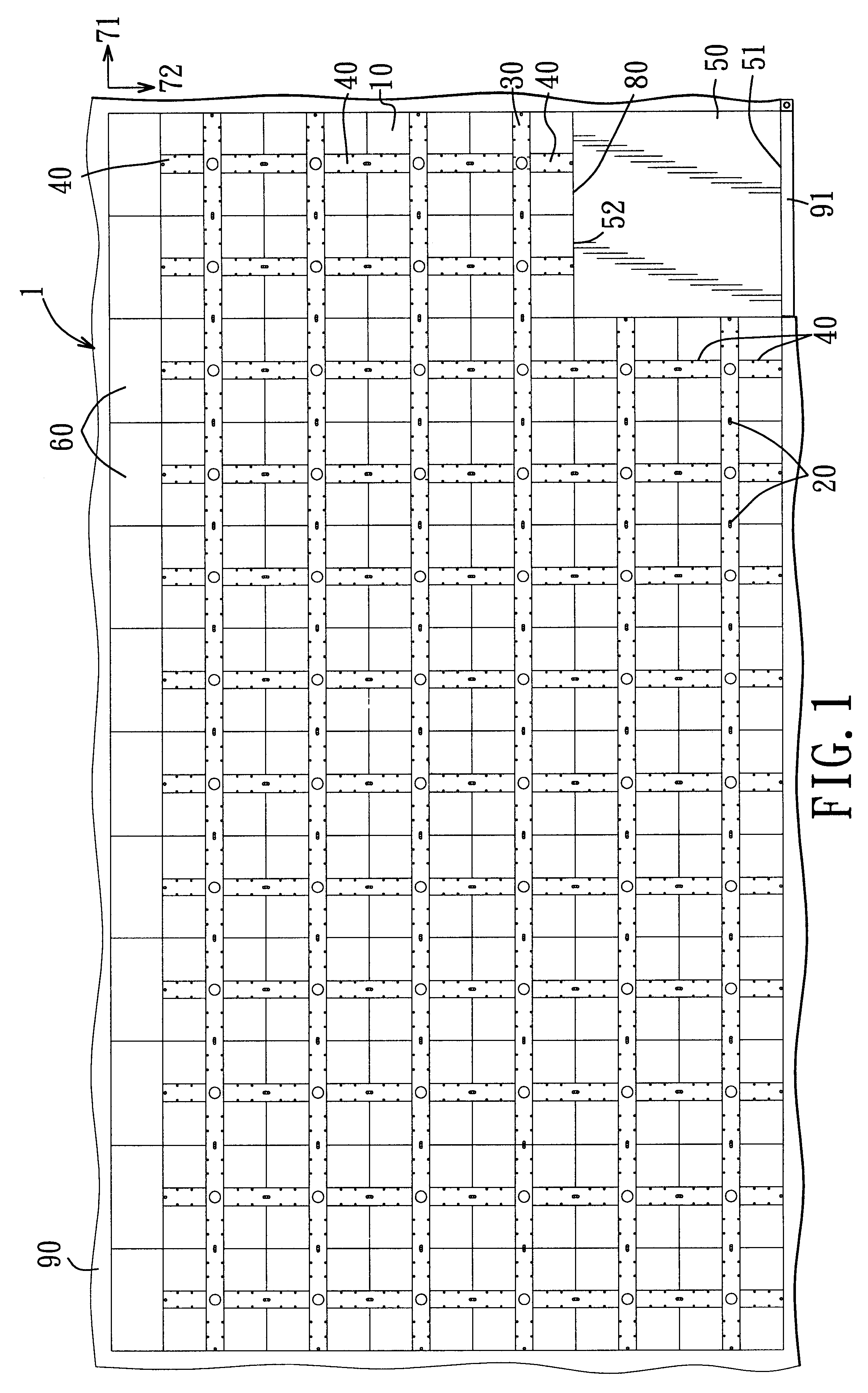

FIG. 1 is a top view of the preferred embodiment of a modular raised floor system according to this invention;

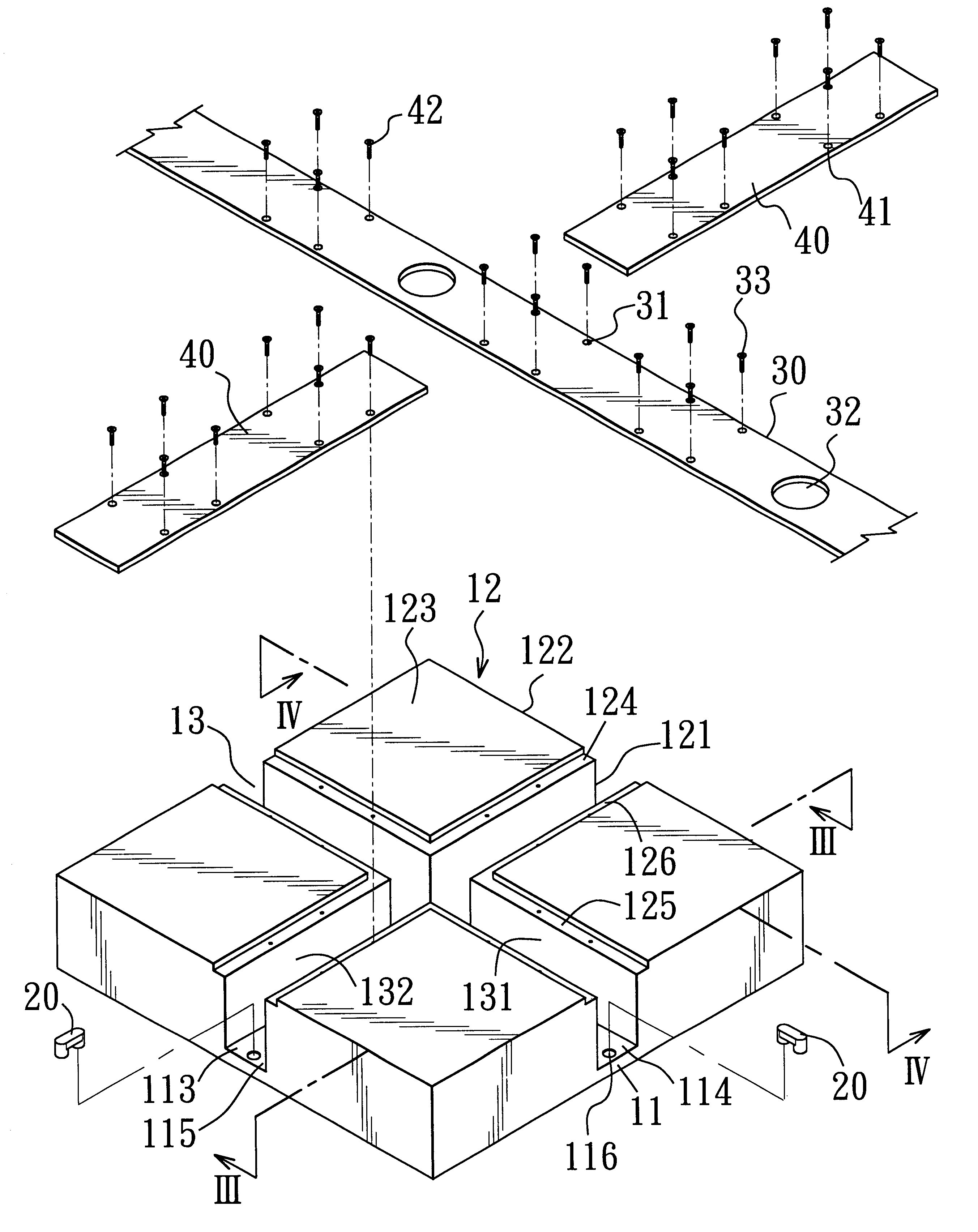

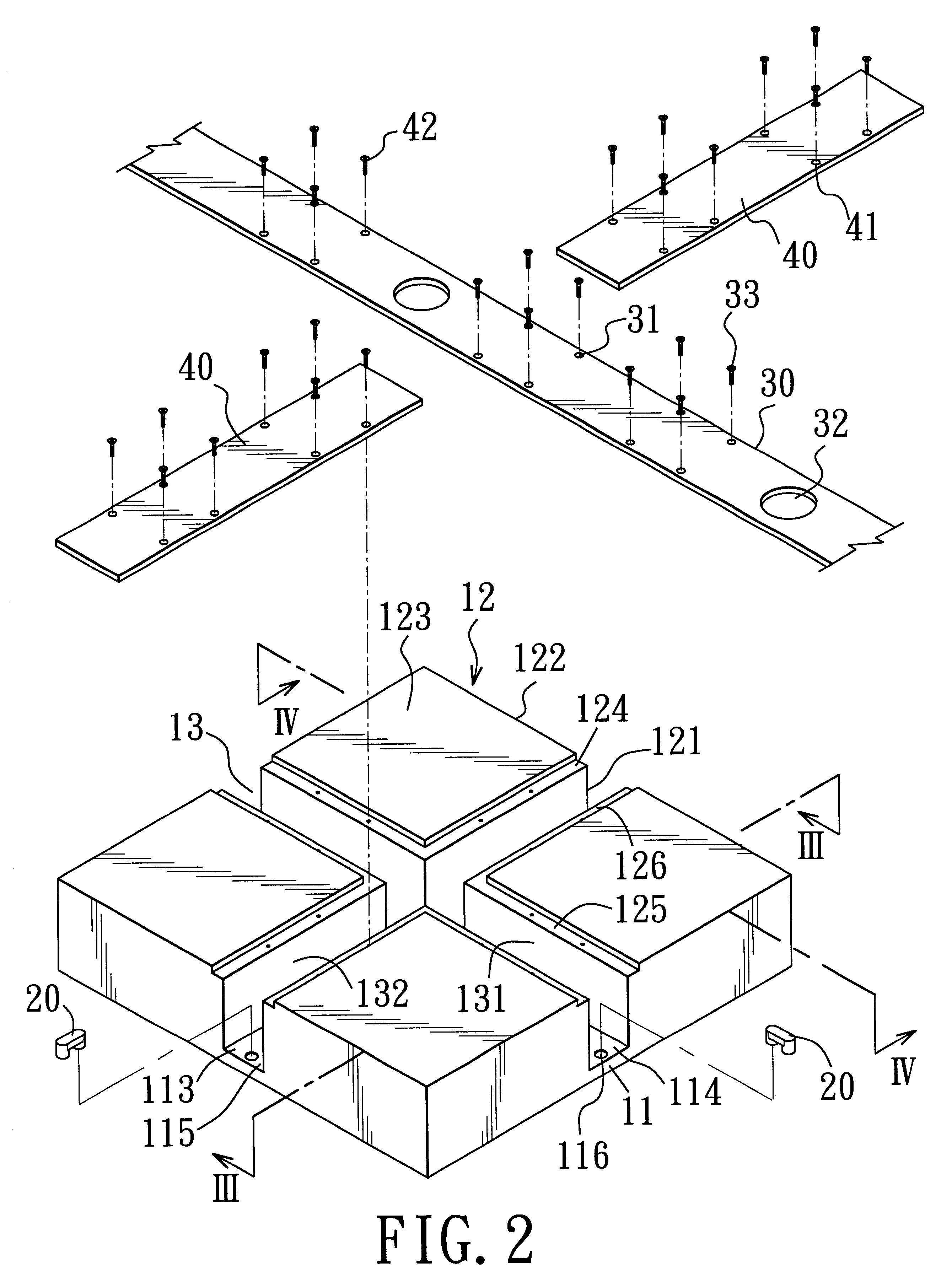

FIG. 2 is an exploded perspective view of one floor panel, one long cover strip, two short cover strips and two positioning members of the preferred embodiment;

FIG. 3 is a sectional view of the floor panel of the preferred embodiment, taken along Line III--III in FIG. 2;

FIG. 4 is a sectional view of the floor panel of the preferred embodiment, taken along Line IV--IV in FIG. 2;

FIG. 5 is a fragmentary top view of the preferred embodiment, illustrating how the floor panels are interconnected;

FIG. 6 is a partly sectional view, illustrating how adjacent two of the floor panels are locked together by the positioning member; and

FIG. 7 is a side view of the preferred em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com