Silicone composite particles, making method, and cosmetic composition

a technology of composite particles and silicone, applied in the field of silicone composite particles, can solve the problems of uv radiation transmission, conventional uv screening cosmetic composition loses its uv screening effect, etc., and achieve the effect of pleasing us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Titanium Oxide-Laden Silicone Resin-Coated Silicone Elastomer Composite Particles

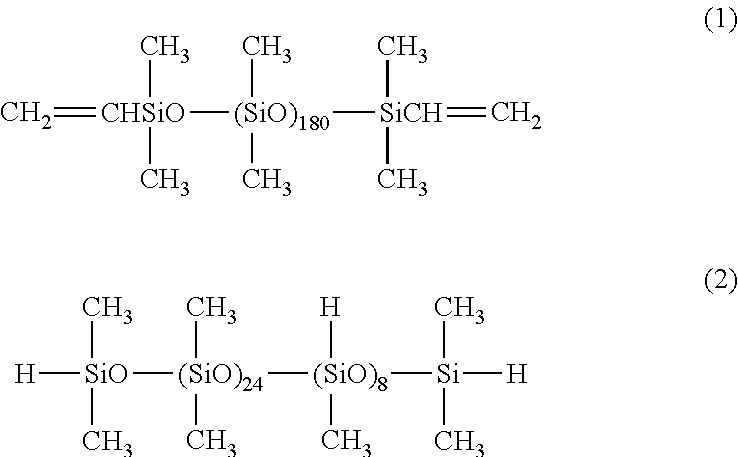

[0126]A glass beaker having a volume of 1 liter was charged with 50 g of methylvinylpolysiloxane of formula (1) having a viscosity of 580 mm2 / s and 19 g of methylhydrogenpolysiloxane of formula (2) having a viscosity of 30 mm2 / s (to give 1.06 hydrosilyl groups per olefinic unsaturated group). Using a homomixer, the ingredients were agitated at 2,000 rpm and dissolved. Then 3 g of polyoxyethylene lauryl ether (molar amount of ethylene oxide added=9 moles) and 55 g of water were added. Using a homomixer, the ingredients were agitated at 6,000 rpm whereupon an oil-in-water type emulsion was formed and a viscosity buildup was observed. Agitation was continued for a further 15 minutes. While agitating at 2,000 rpm, 421 g of water was added to the emulsion which turned into a uniform white emulsion. The emulsion was transferred into a 1-liter glass flask equipped with an agitator having an anchor shaped impel...

example 2

Iron Oxide-Laden Silicone Resin-Coated Silicone Elastomer Composite Particles

[0132]As in Example 1, a water dispersion of silicone elastomer spherical particles was prepared. 867 g of the water dispersion of silicone elastomer spherical particles was transferred into a 3-liter glass flask equipped with an agitator having an anchor shaped impeller, to which were added 33 g of a water dispersion of iron oxide nano-particles (trade name, JC-FH04, by JFE Chemical Co., Ltd., average particle size 70 nm) (to give 7.3 parts of iron oxide per 100 parts of silicone elastomer spherical particles), 10 g of 30 wt % dodecyltrimethylammonium chloride aqueous solution, 1,975 g of water and 57 g of 28 wt % ammonia water. At this point, the liquid was at pH 11.2. After it was conditioned at 5-10° C., 58 g of methyltrimethoxysilane (to give 6.3 parts of polyorganosilsesquioxane per 100 parts of silicone elastomer spherical particles after hydrolytic condensation reaction) was added dropwise over 20 m...

example 3

Zinc Oxide-Laden Silicone Resin-Coated Silicone Elastomer Composite Particles

[0135]As in Example 1, a water dispersion of silicone elastomer spherical particles was prepared. 867 g of the water dispersion of silicone elastomer spherical particles was transferred into a 3-liter glass flask equipped with an agitator having an anchor shaped impeller, to which were added 51 g of a water dispersion of zinc oxide nano-particles (trade name, ZW-143, by Sumitomo Osaka Cement Co., Ltd., zinc oxide concentration 30 wt %, average particle size 20 nm) (to give 3.4 parts of zinc oxide per 100 parts of silicone elastomer spherical particles), 1,967 g of water and 57 g of 28 wt % ammonia water. At this point, the liquid was at pH 11.3. After it was conditioned at 5-10° C., a mixture of 58 g of methyltrimethoxysilane and 2 g of γ-aminopropyltrimethoxysilane (to give 6.4 parts of polyorganosilsesquioxane per 100 parts of silicone elastomer spherical particles after hydrolytic condensation reaction) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume average particle size | aaaaa | aaaaa |

| volume average particle size | aaaaa | aaaaa |

| volume average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com