Flashlight and recharging system therefor

a rechargeable and flashlight technology, applied in the manufacture of electric torches/pocket-lamps, secondary cell manufacturing, final product manufacturing, etc., can solve the problems of increased manufacturing costs, and increased manufacturing costs of flashlights

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

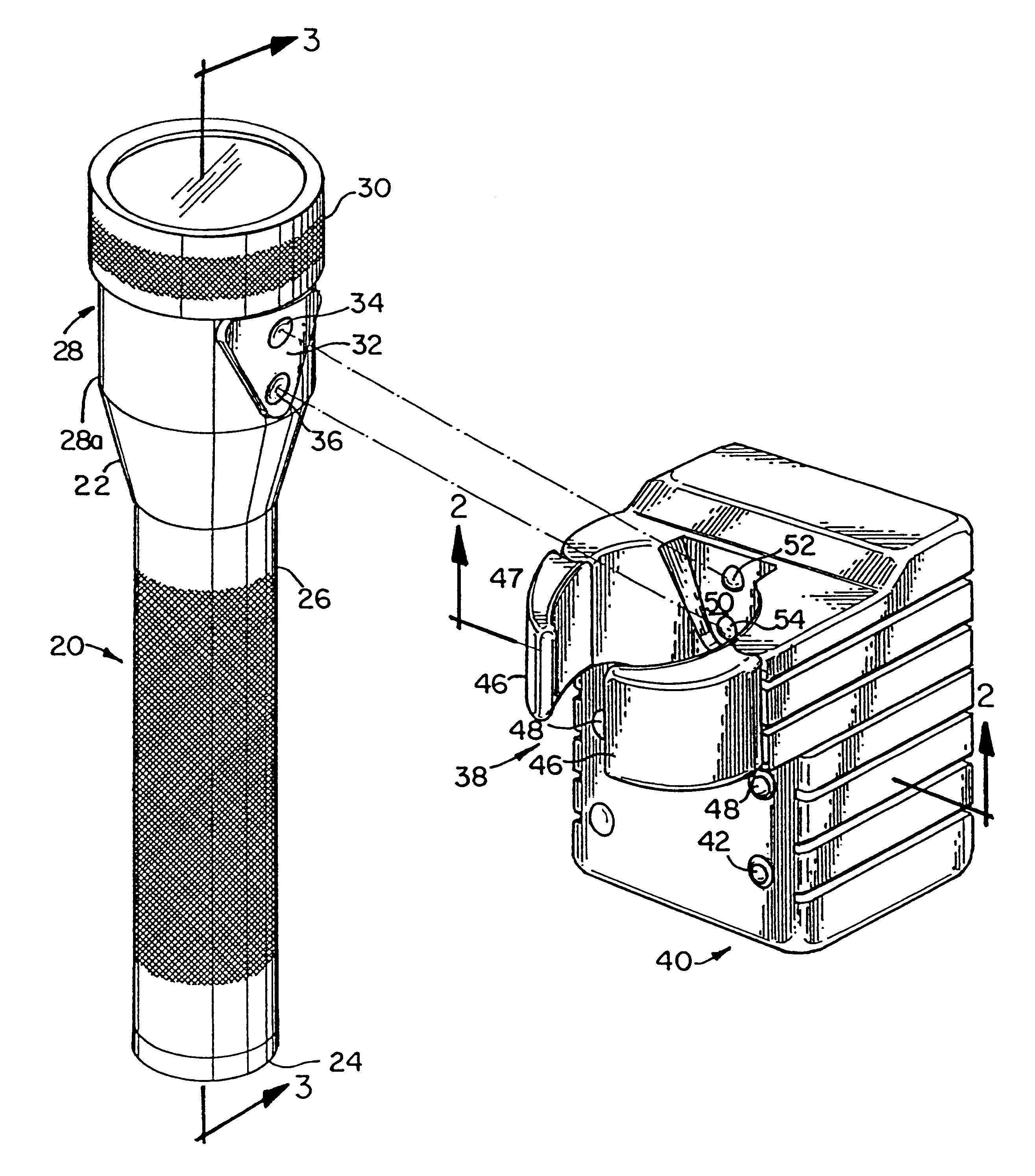

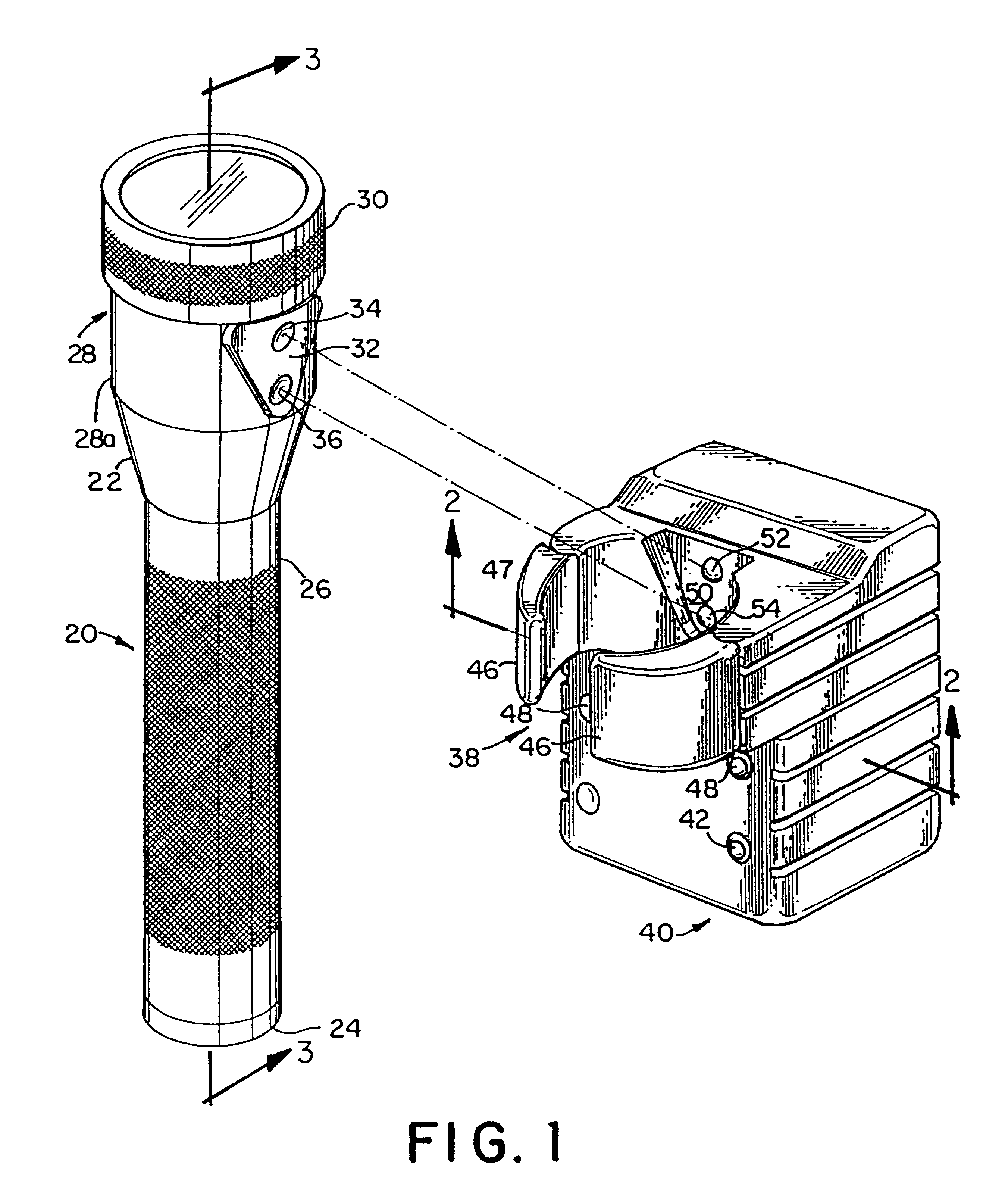

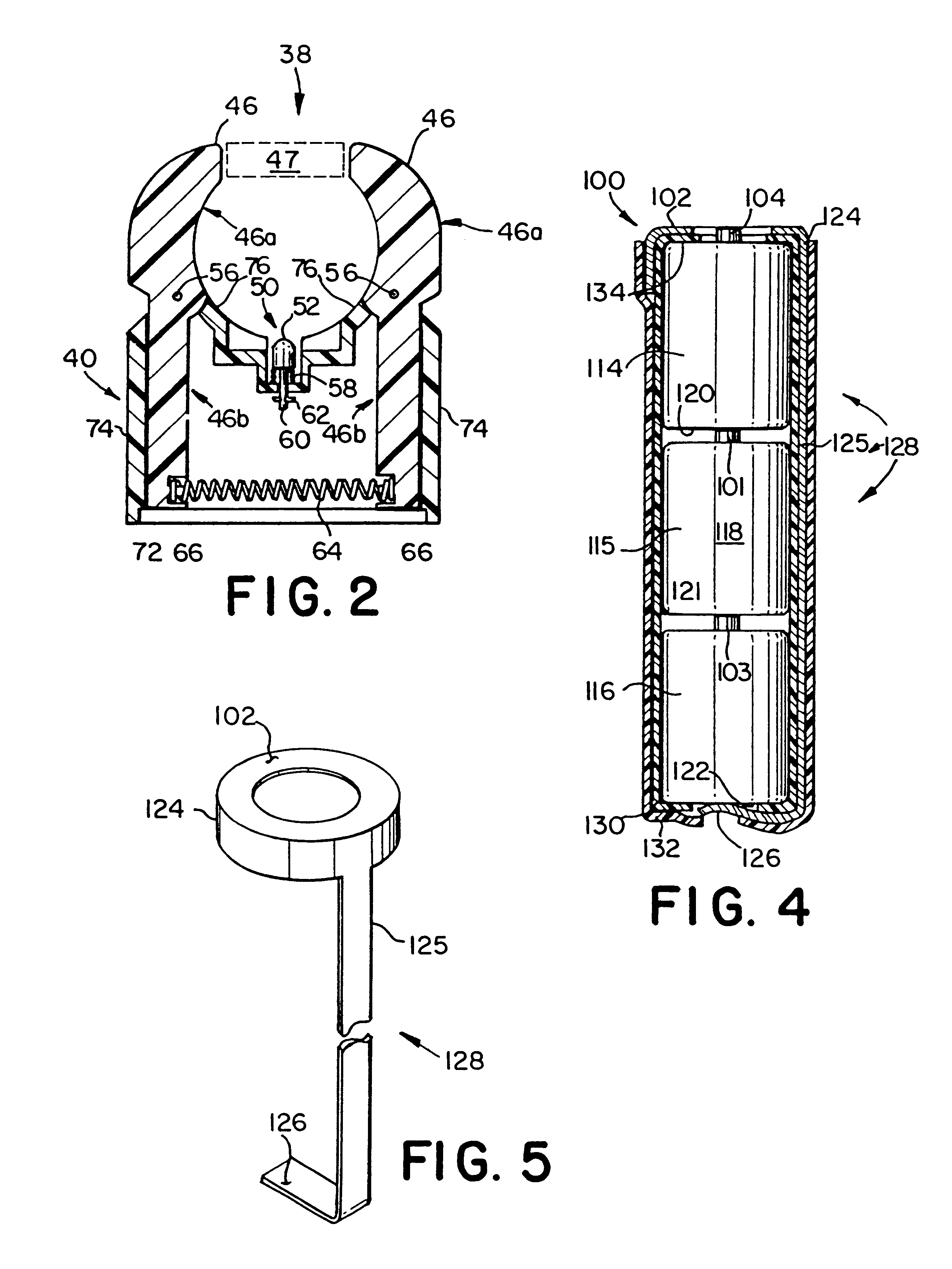

Referring to FIG. 1, there is shown a flashlight 20 and a charging unit 40. The flashlight 20 includes a head assembly 28, a barrel 26, and a tail cap 24. A guide means, such as triangular guide plate 32, is mounted on the side of the head 28. A pair of charging contacts such as concave contacts 34 and 36 are located in the guide plate 32. The guide plate mates with an alignment recess 50 of the charging unit 40, when the flashlight 20 is placed into the charging unit 40. The charging unit 40 includes a pair of jaws 46, a receptacle generally designated 38 which includes the alignment recess 50, and a pair of convex charging terminals 52 and 54 in the alignment recess 50. The recess 50 is shaped to receive and align the guide plate 32, so that the charging terminals 52 and 54 of the charging unit 40 mate with respective charging contacts 34 and 36, when the flashlight is received or mounted in the charging unit 40. The jaws 46 snugly grip the head 28 of the flashlight 20 with a grip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| electrical energy | aaaaa | aaaaa |

| resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com