Stiffened vehicle structure with cantilever reinforcing member

A vehicle and cantilever technology, which is applied to the rear frame field, can solve the problems of reducing the reliability of the vehicle, not being able to be installed in the original place, and damaging the driving stability of the vehicle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

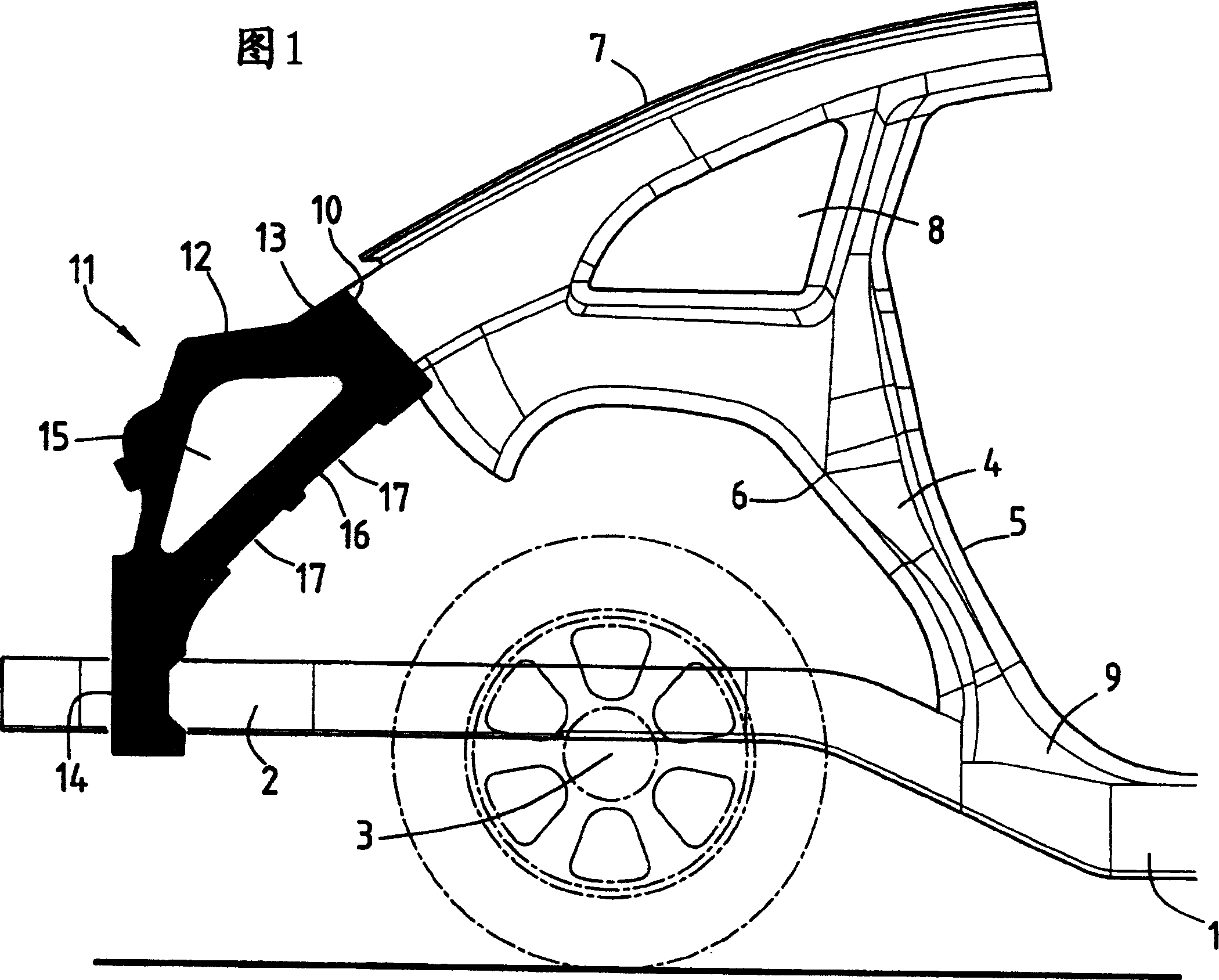

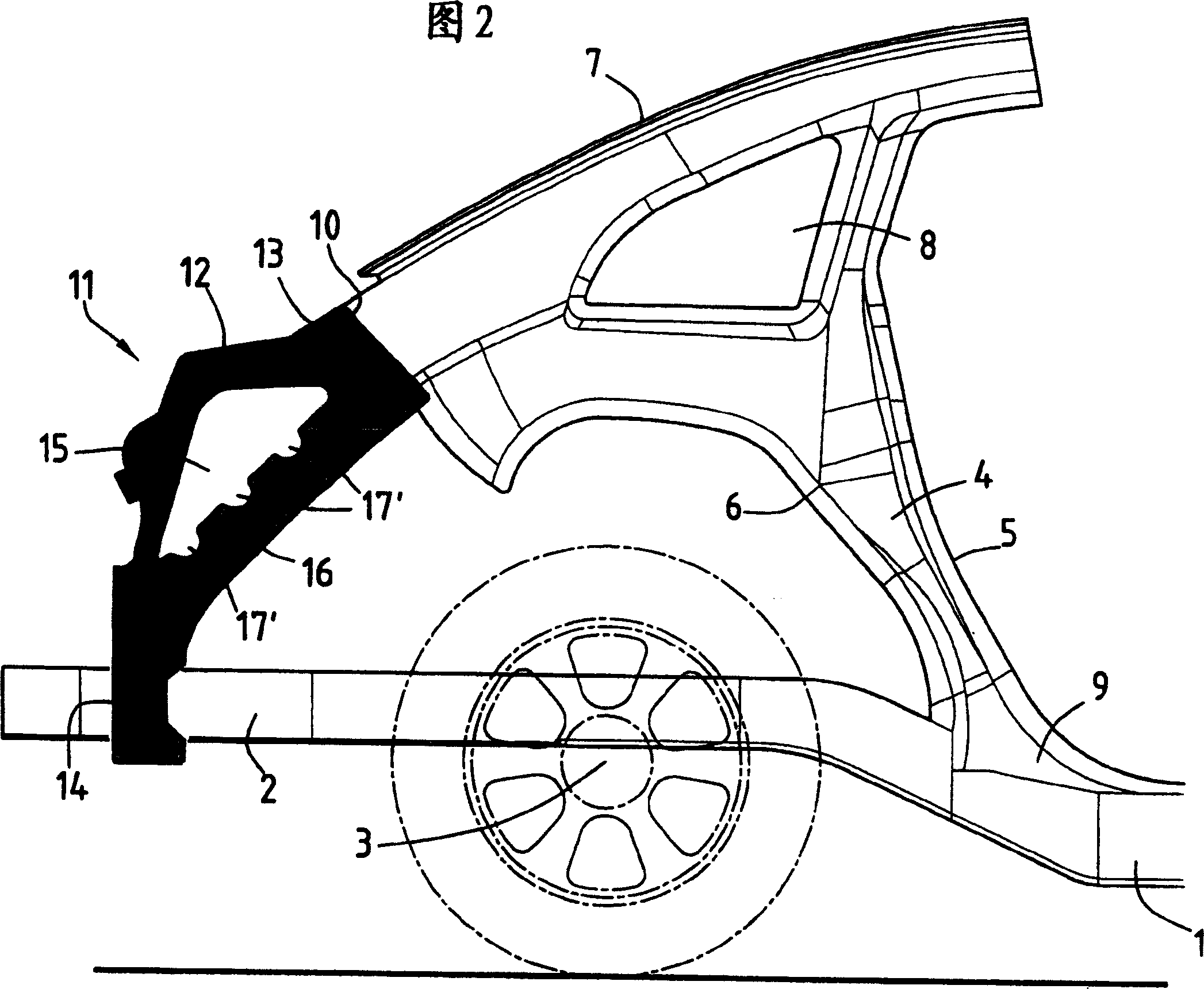

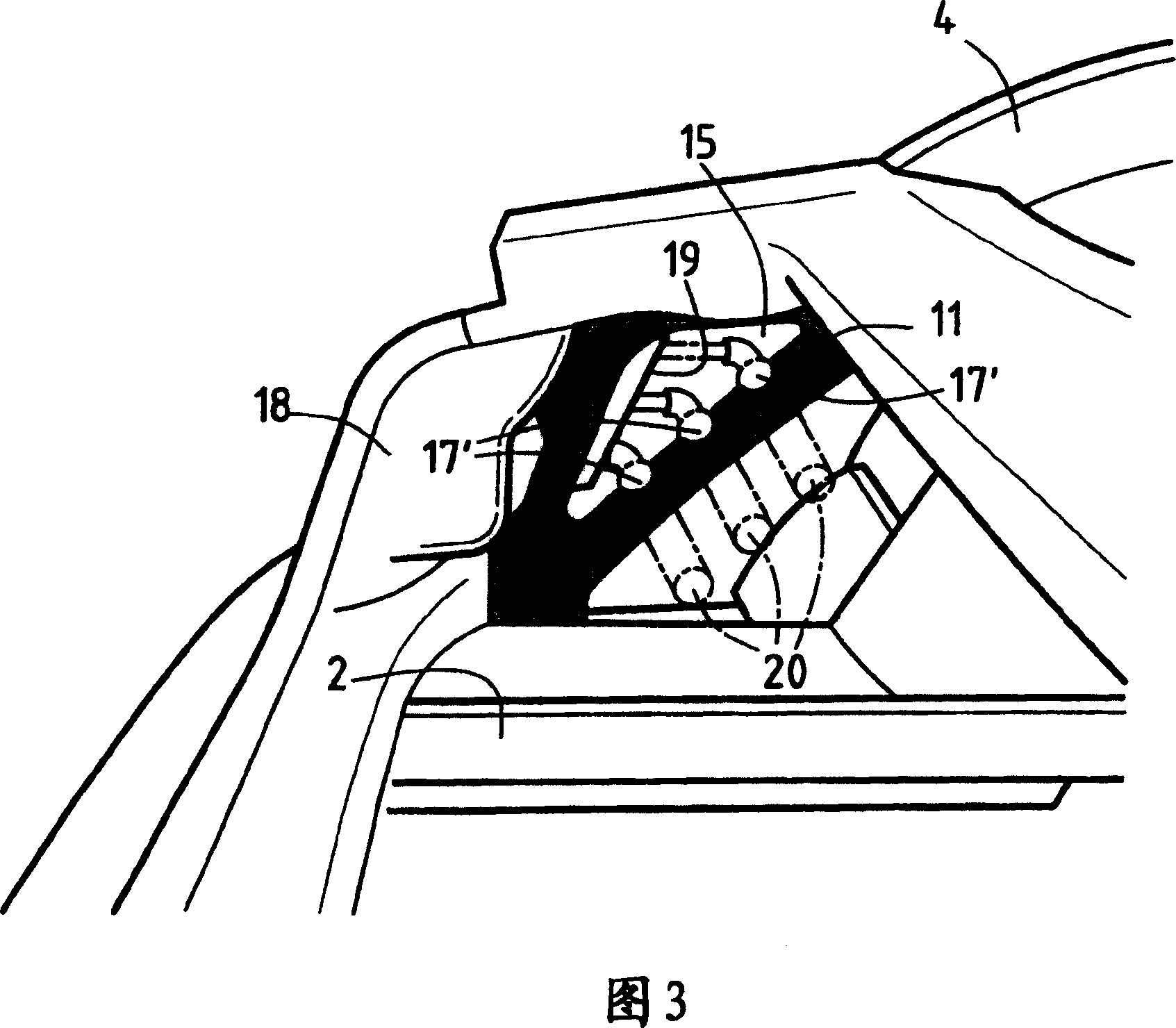

[0018] The body frame of a motor vehicle shown in FIG. 1 comprises a base, which in particular consists of two parallel longitudinal beams 1 which extend towards the rear of the vehicle with two longitudinal beam extensions 2 (in the figure , only one stringer and one stringer extension are shown).

[0019] The junction of each side member extension 2 and each side member 1 is located in the vicinity of a point which is vertically above the axis of rotation 3 of the respective rear axle, ie approximately aligned with the vehicle rear axle.

[0020] Each rear portion of the cab frame is constituted by a quarter panel reinforcement liner 4 (only one of which is shown in the figure) which is supported by the side members 1 and extends upwardly from the vehicle floor.

[0021] The rear side panel reinforcement liner 4 is a known component and has a complicated shape. It has an edge 5 which partly delimits the closed area of the rear door of the vehicle, an edge 6 which partly d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com