Optical fiber drawing method and drawing furnace

A technology of drawing furnace and optical fiber, applied in glass fiber drawing device, optics, light guide and other directions, can solve the problems of melting, overheating of the inner wall of the base material holding cylinder, and the drawing of optical fiber cannot be carried out normally, and achieve reliable diameter, prevent damage, The effect of preventing overheating of the shoulders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, the preferred embodiment of the present invention will be described in detail with reference to the accompanying drawings. In order to make the description easy to understand, in each figure, the same structural elements are assigned the same reference numerals as much as possible, and repeated descriptions are omitted.

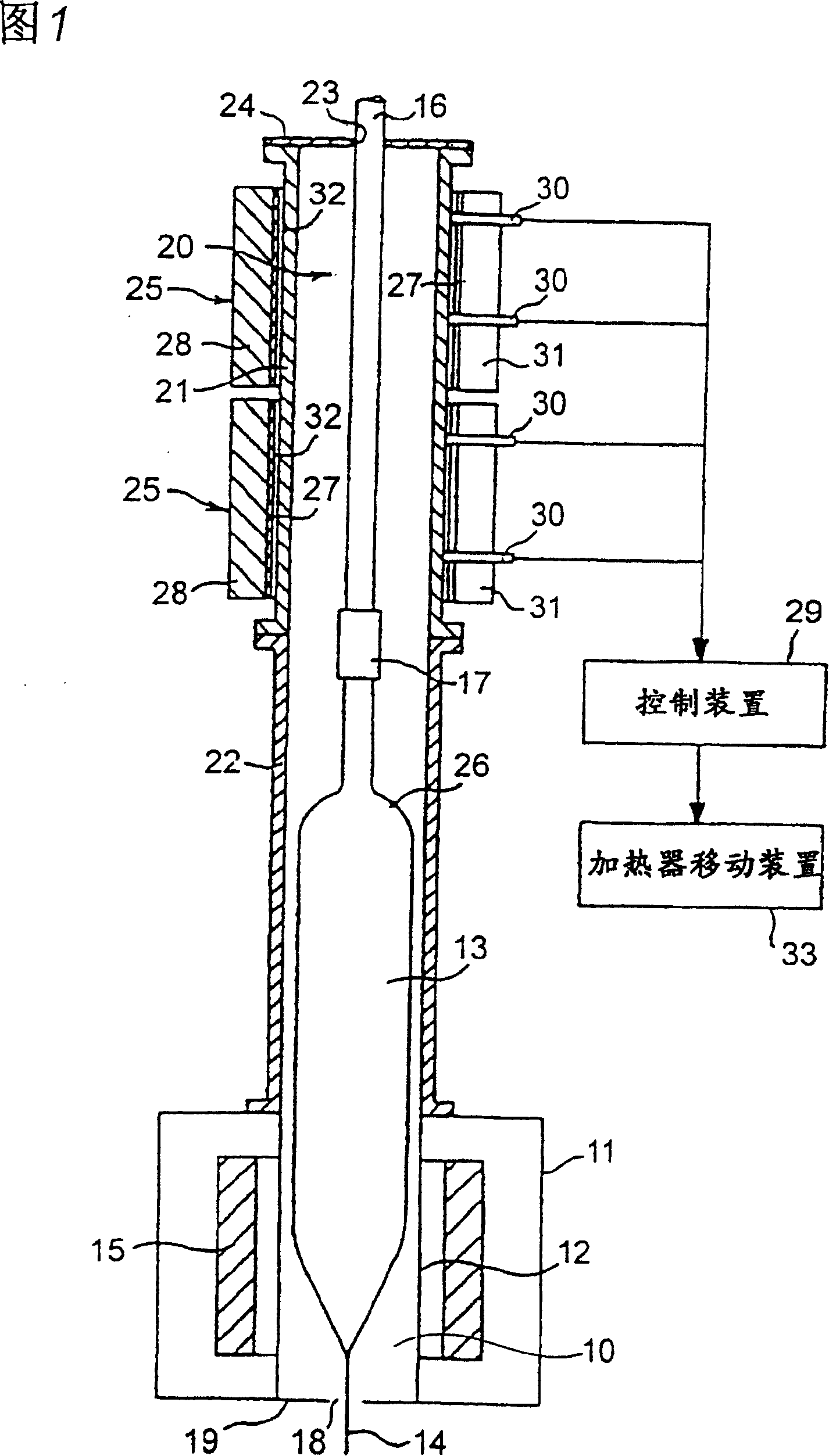

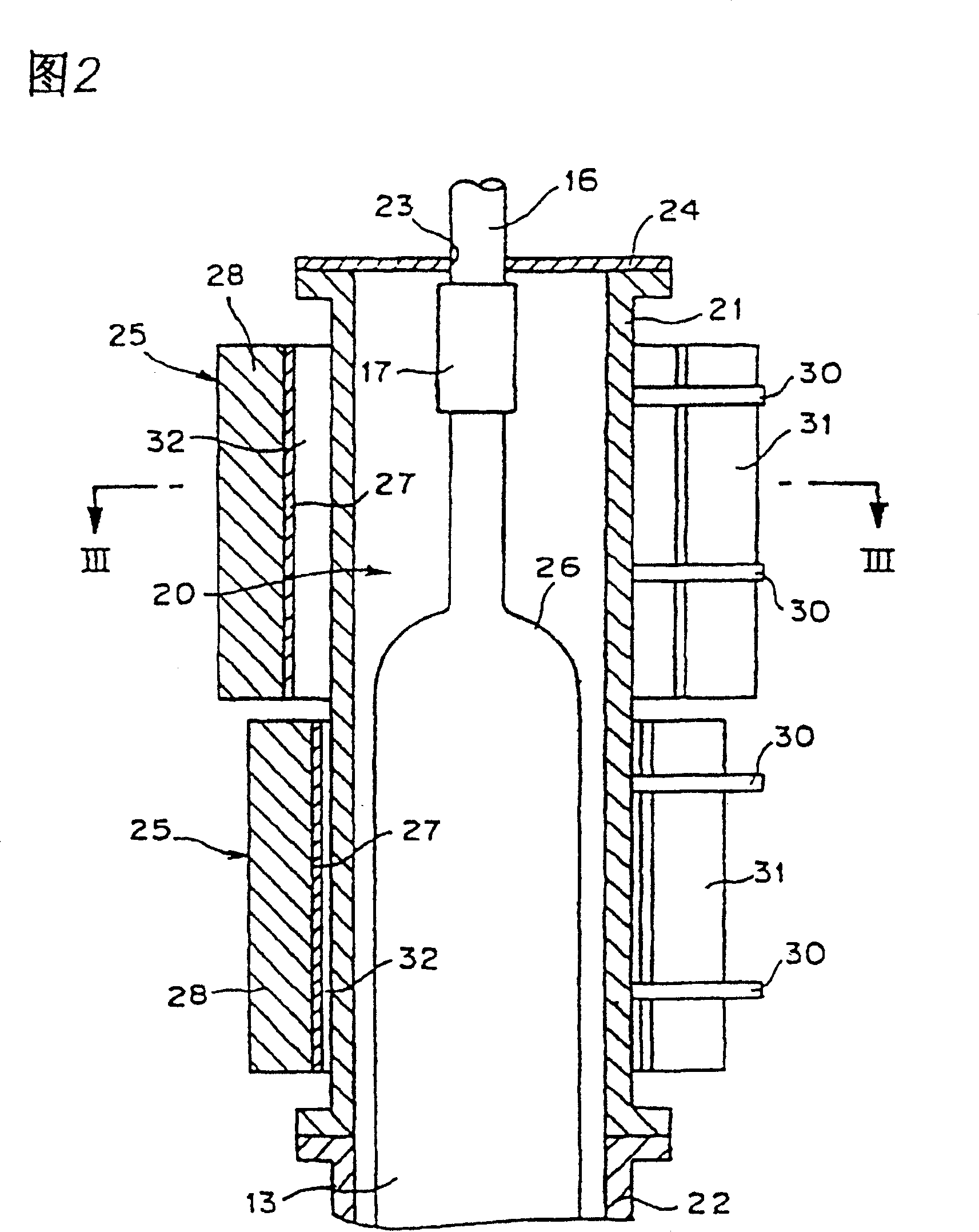

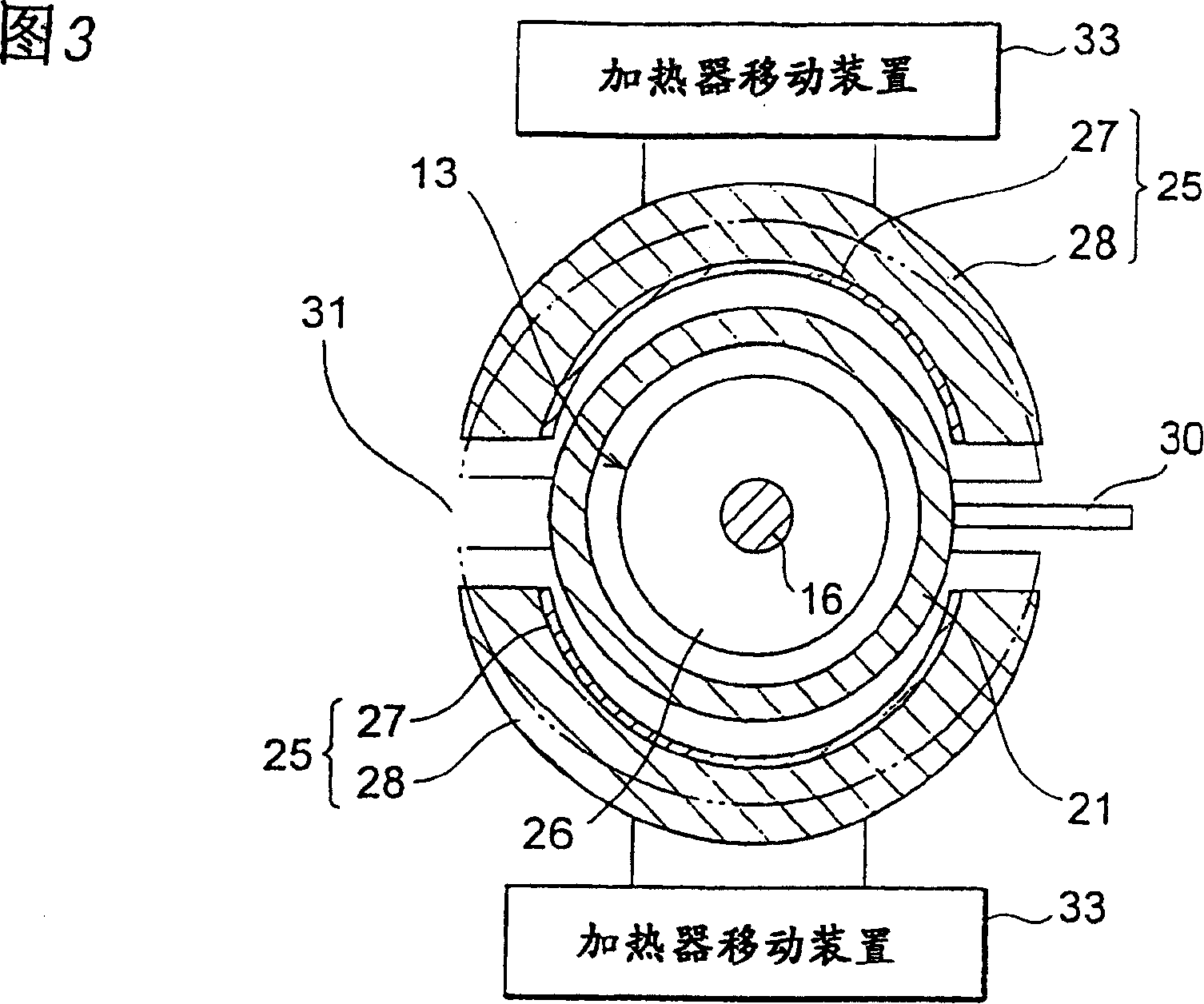

[0024] 1 is a sectional view showing the structure of a first embodiment of an optical fiber drawing furnace according to the present invention, FIG. 2 is an enlarged view showing its main parts, and FIG. 3 is a III-III sectional view in FIG. 2 .

[0025] The fiber drawing furnace is equipped with a furnace body 11 made of stainless steel and lined with heat insulating material. A cylindrical furnace core tube 12 is arranged at the central portion of the furnace body 11 , and an annular graphite heater 15 is arranged around it, that is, between the furnace body 11 . The furnace tube 12 and the graphite heater 15 are arranged concentricall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com