Picker guiding structure of optical disk drive

A technology of optical disc drives and optical pickups, which is applied in the directions of driving/moving recording heads, configuration/installation of heads, etc., can solve the problems such as the increase in the number of integral parts of the optical disc drive, the increase in the occurrence rate of bad phenomena, and the decrease in operational reliability, etc. Achieving the effect of improving operational reliability, minimizing the accumulation of mounting tolerances, and improving operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

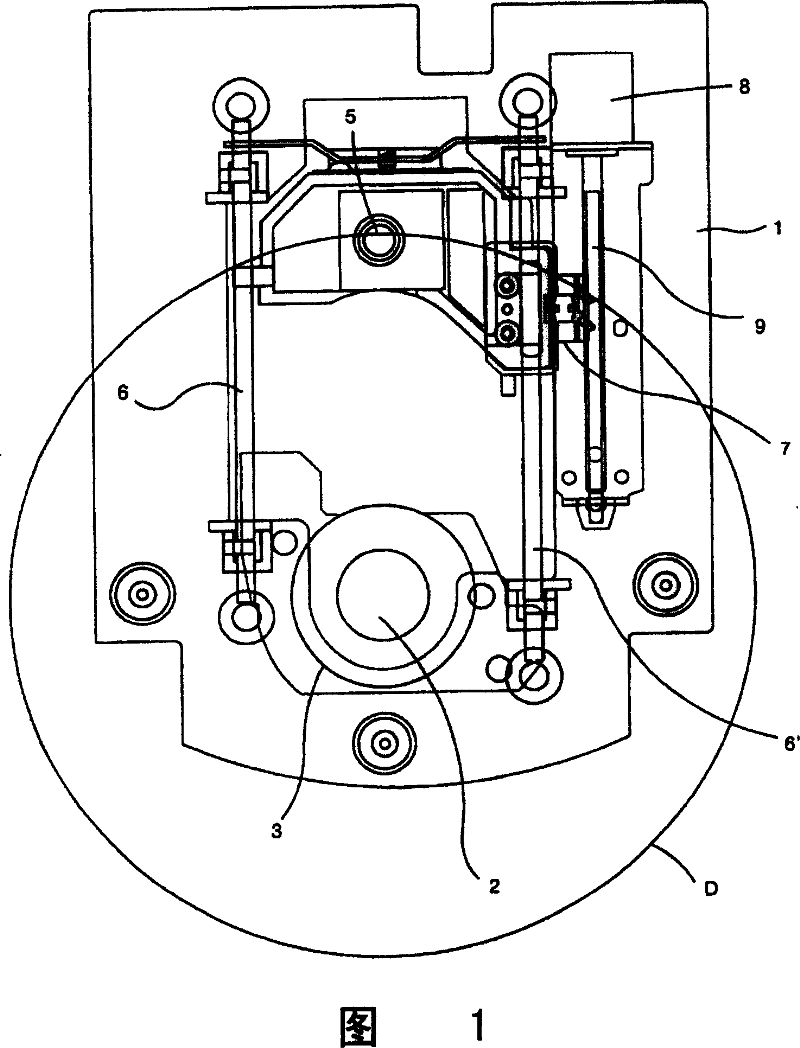

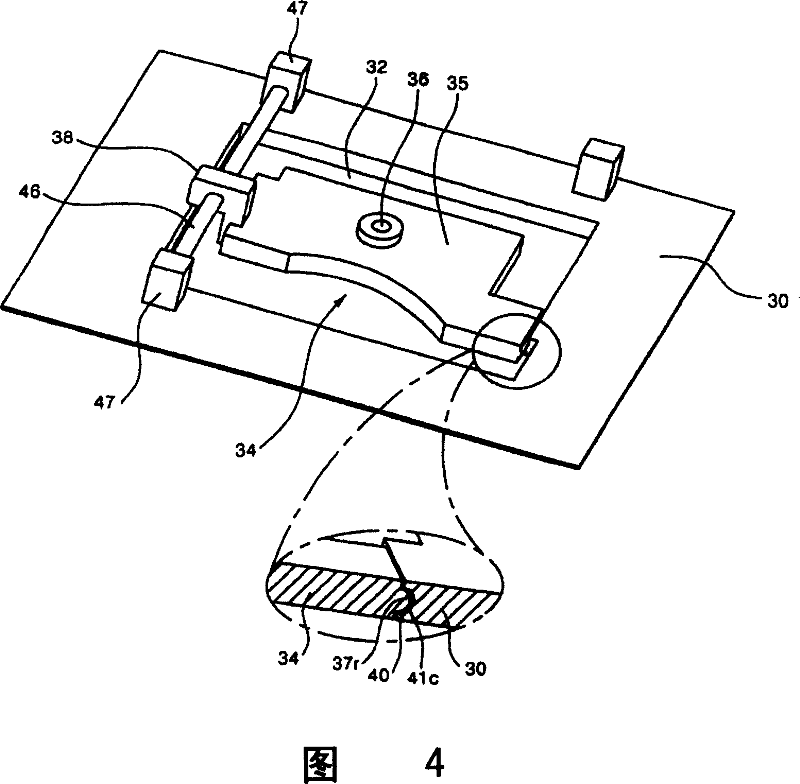

[0024] Hereinafter, an ideal embodiment of the guide structure of the optical pickup of the optical disc drive of the present invention will be explained in detail with reference to the accompanying drawings.

[0025] Fig. 2 is a schematic perspective view of a preferred embodiment of the guide structure of the optical pickup in the present invention. Fig. 3 is a perspective view of the configuration of the main part of the embodiment shown in Fig. 2.

[0026] As shown in the figure, in this embodiment, the optical pickup base 30 is mounted on the main frame (not shown) of the optical disc drive. The pickup base 30 is provided with a spindle motor for disk rotation, an optical pickup 34 for recording and reading signals on the disk, and the like.

[0027] The above-mentioned pickup base 30 is preferably made of a metal material, and one end of the pickup base 30 can be integrated with an accessory made of synthetic resin by means of an embedded model. The pickup base 30 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com