Grinding head adjusting structure of grinding apparatus

A technology for adjusting the structure and grinding head, which can be used in coffee mills, spice mills, household appliances, etc., and can solve the problems that the cutter head cannot be ground, and there is no grinding effect memory function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with embodiment the present invention is described in further detail.

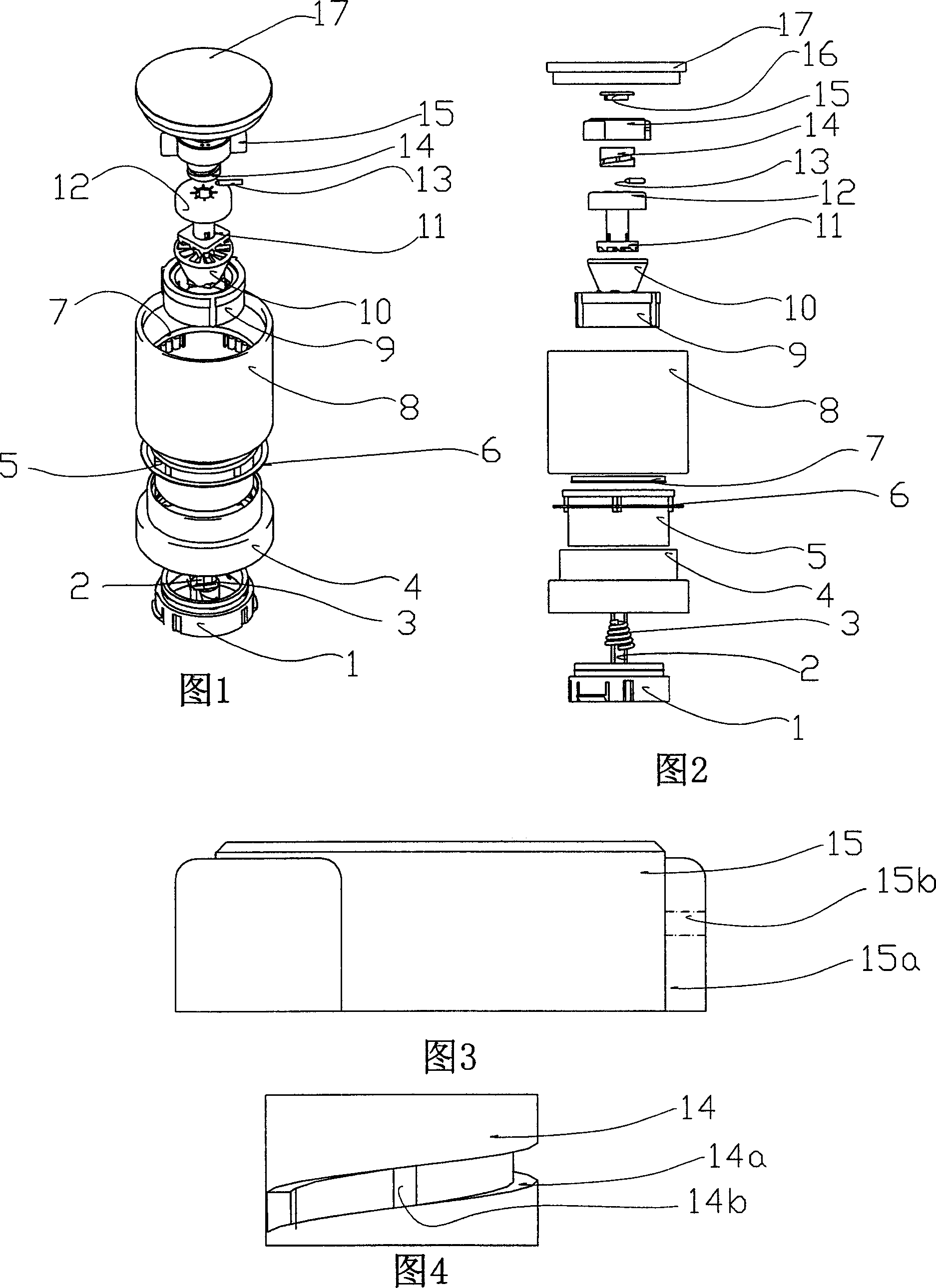

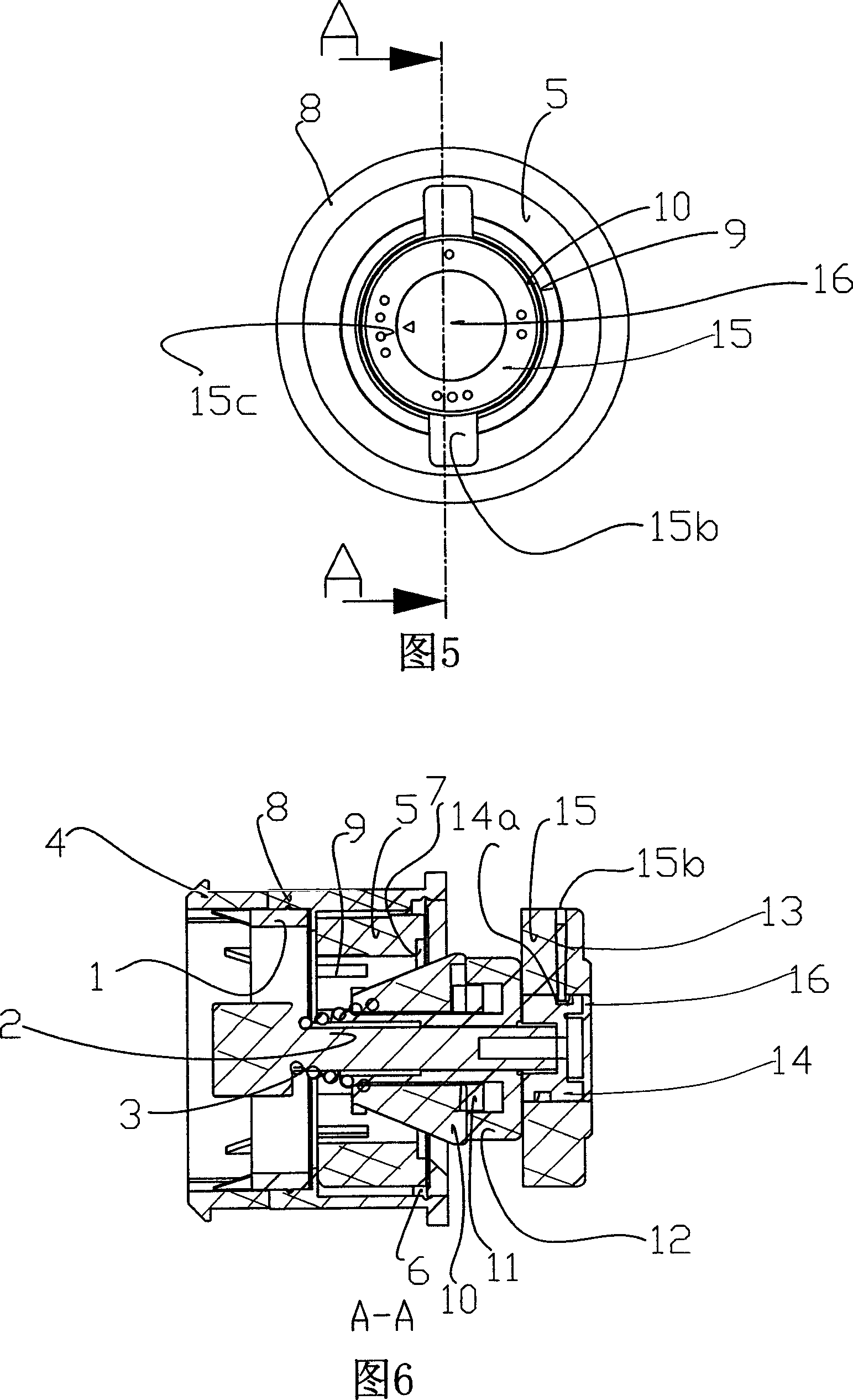

[0020] As shown in Fig. 1 to Fig. 6, it is an optimized embodiment of the present invention. The grinding head adjustment structure of the grinder includes a base 1 embedded in the lower ring 4 of the grinding head. The base 1 is provided with an upwardly extending middle rod 2 sequentially fitted with a spring 3, a cutter head 10, and a backstop gear 11, the cutter head cap 12, and the upper end of the middle rod 2 is threaded with an adjustment cap, the cutter head 10 is matched with the cutter head seat 9 in the cutter seat cover 5 of the middle ring 8 cavity, and the lower end of the middle ring 8 is screwed and ground The connecting ring 4 under the head, the adjustment cap is composed of the shaft core cover 16, the adjustment disc 15, the adjustment shaft core 14, and the spring thimble 13; the adjustment shaft core 14 is threaded on the upper end of the middle rod 2, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com