Fault monitoring and expert system for rubber banburying producing process and its using method

An expert system and production process technology, applied in the field of fault monitoring systems, can solve problems such as the inability to discover or predict abnormal phenomena in time, the inability to accurately judge whether the conveying device is normal, and the large influence of human subjectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

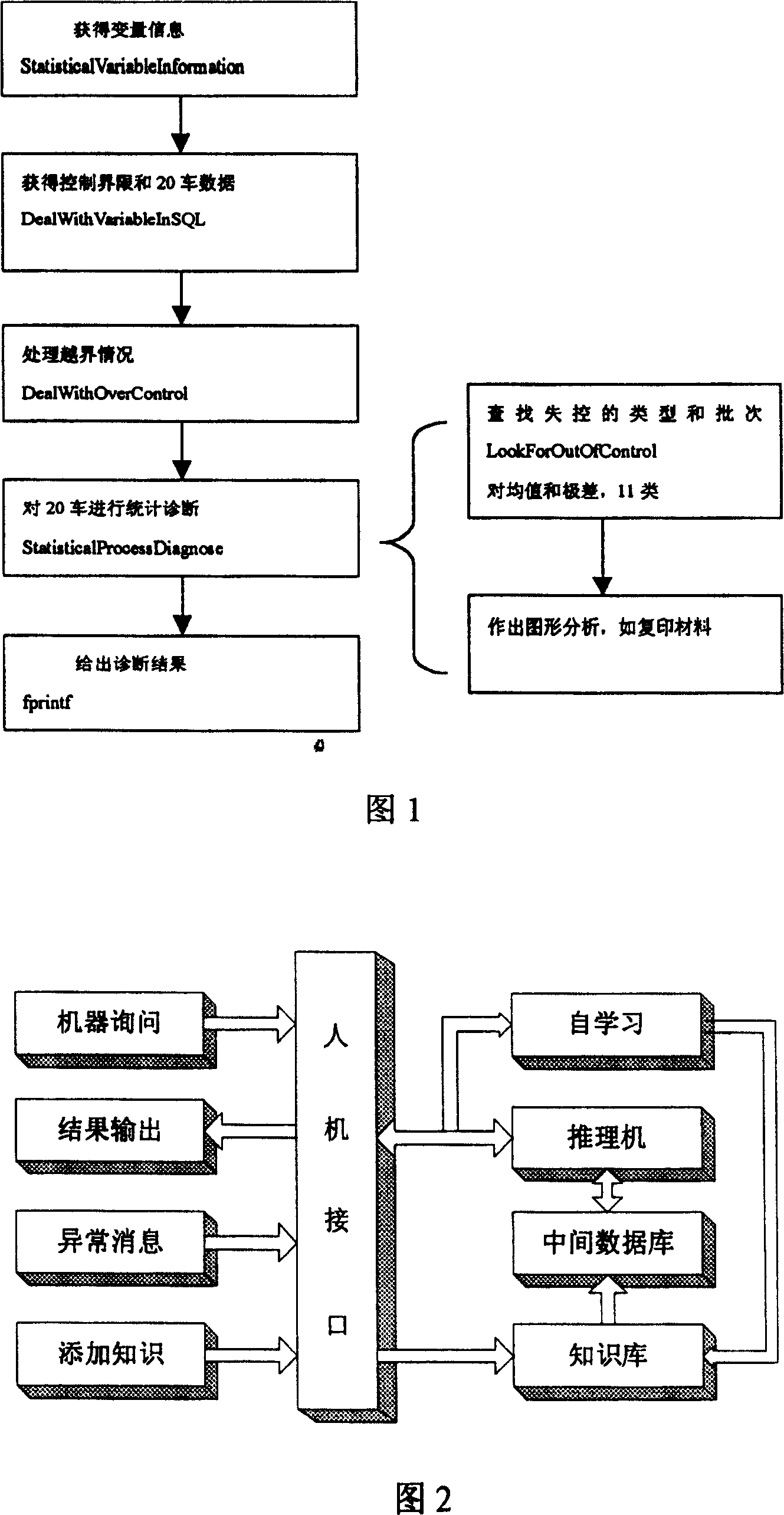

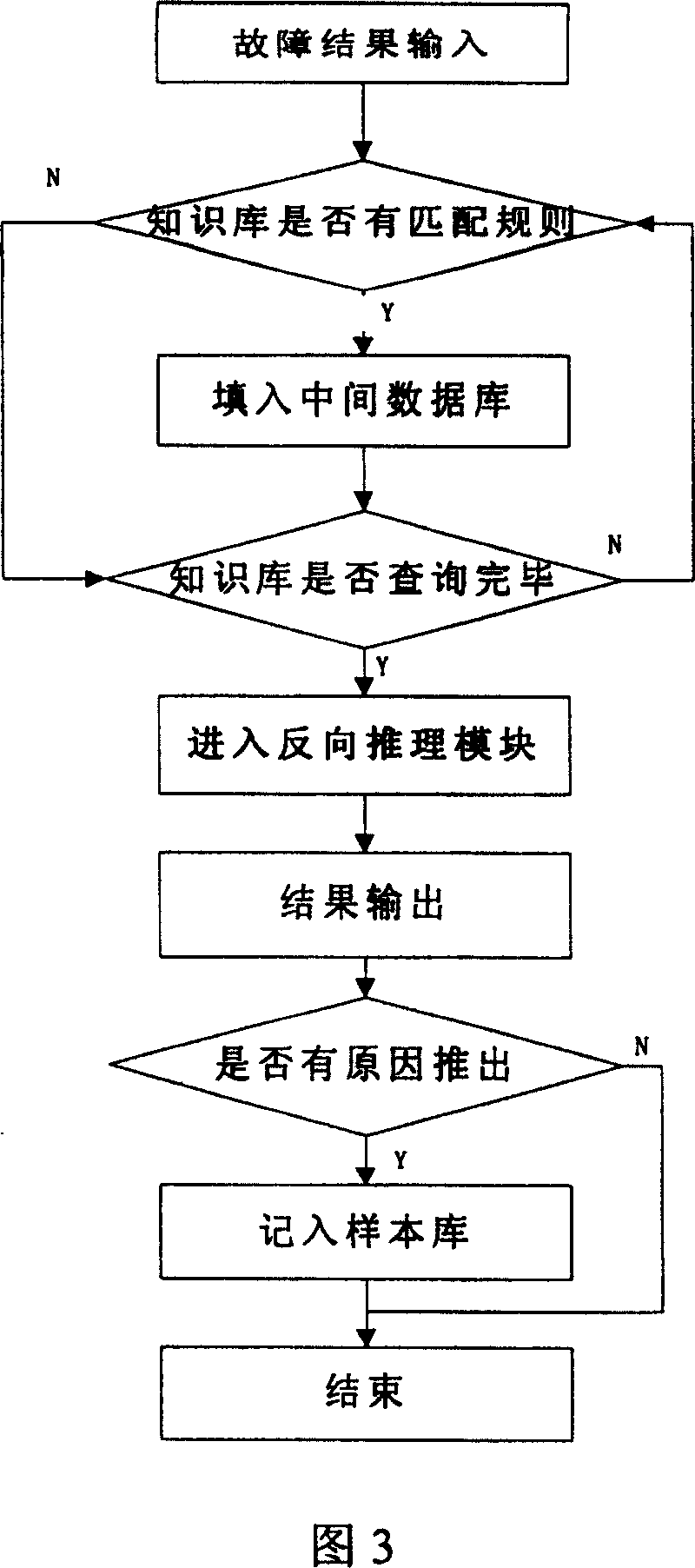

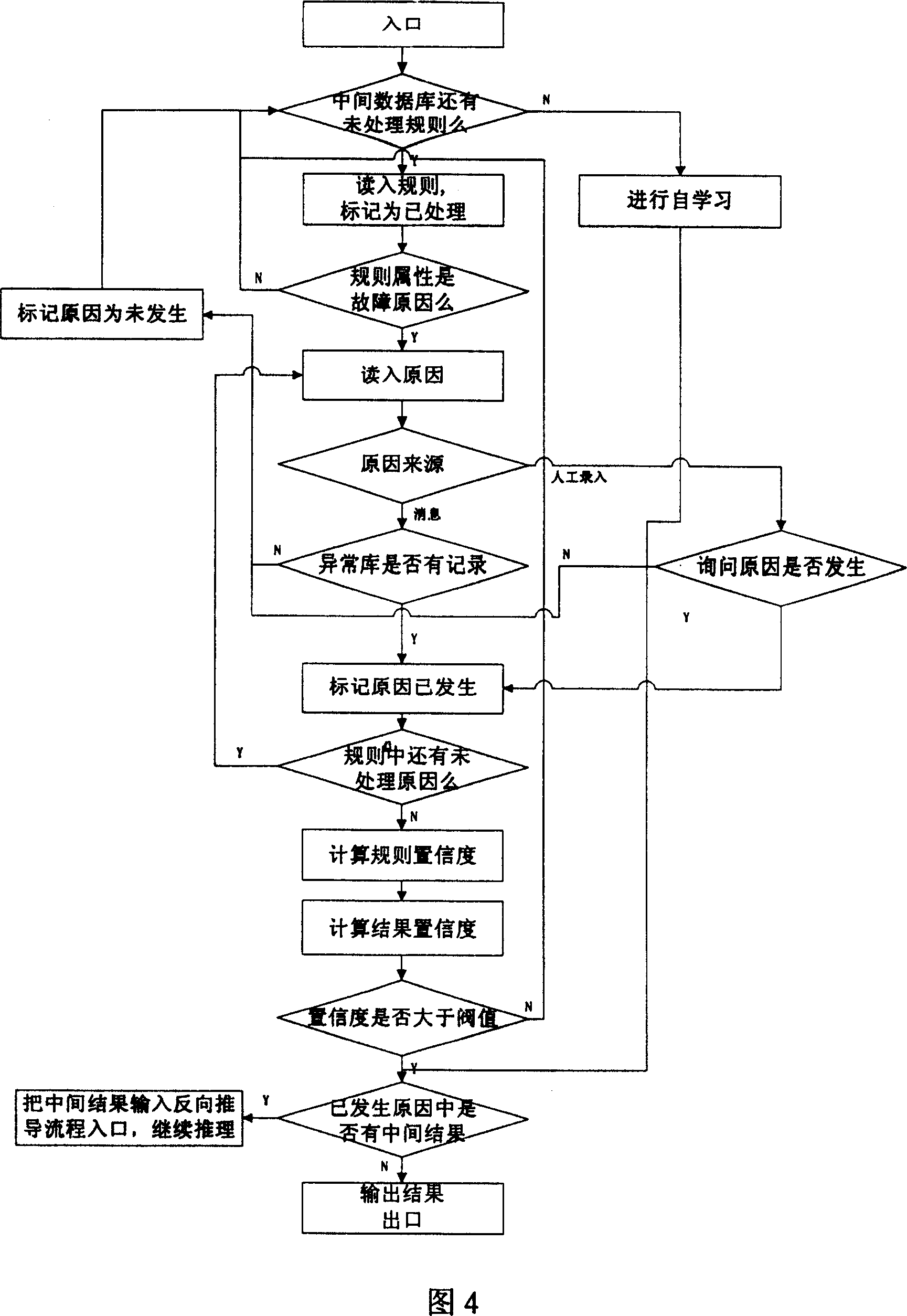

[0034] The fault monitoring and expert system of the rubber mixing production process described in the present invention and its use method, in order to realize the reliable evaluation of the production process, so as to judge whether the process is out of control and whether the process is capable, it is necessary to use the monitoring system to monitor Establish data models and collect and sort out process status judgment standards and scales.

[0035] The monitoring system performs statistics, analysis and output backup on the process data in the production process, such as the time of adding carbon black and slipping time, so as to form a data curve reporting the state of the whole process, which can give early warning to abnormal states, and The type and nature of the abnormality are specifically determined and the corresponding corrective measures are suggested.

[0036] The monitoring system records and stores data in the form of a database for sharing, and can dynamica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com