Method for realizing regional grid points in PCB design

An implementation method and grid technology, applied in the field of electronics, can solve the problems of cumbersome implementation of grid system, low PCB design accuracy and design efficiency, and not widely used grid, so as to reduce work intensity, improve efficiency, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

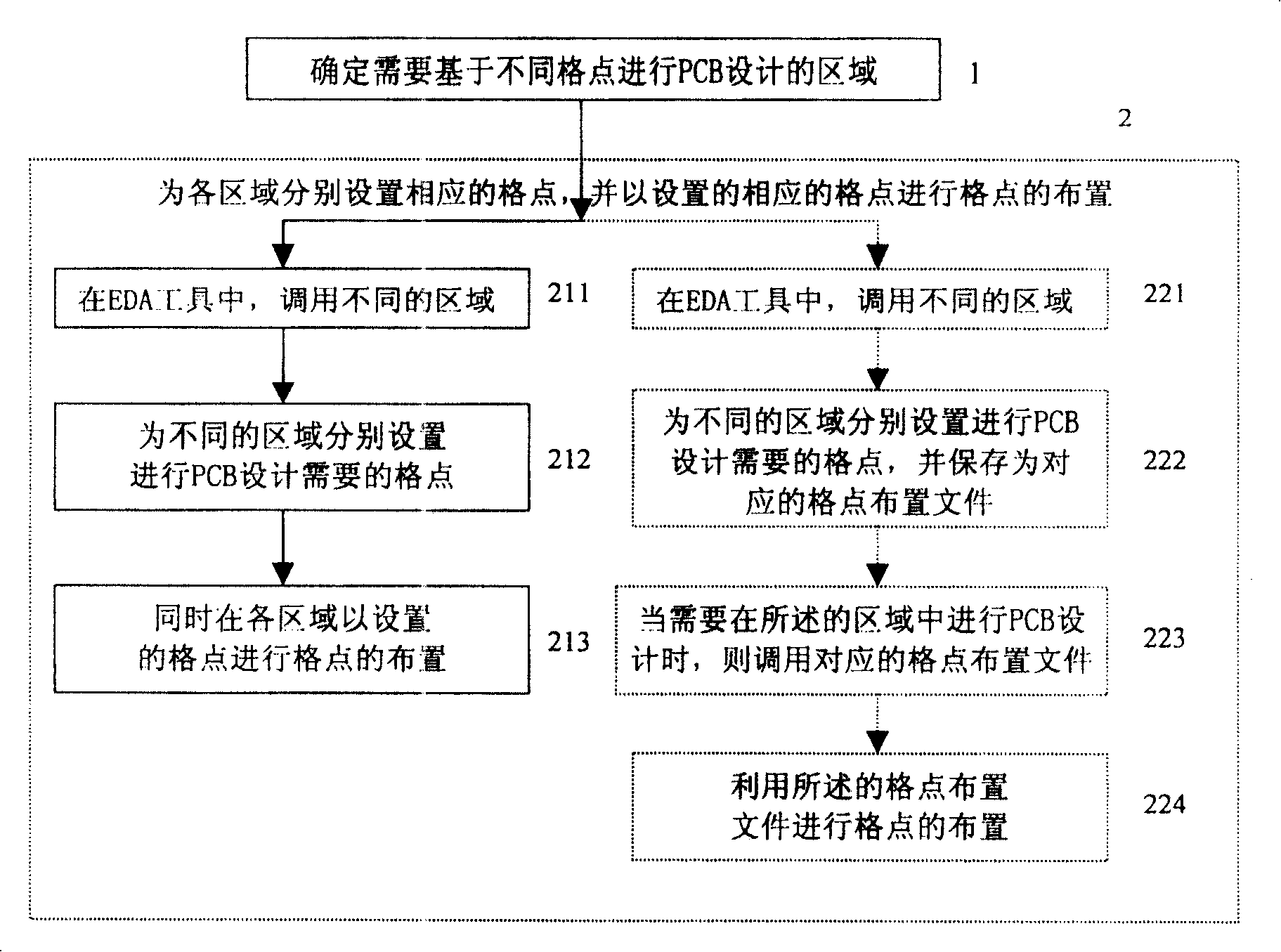

[0031] The core of the present invention is to provide an effective grid point layout method for PCB design tools, so that different areas can be provided with grid points required for design during the PCB design process, and different areas correspond to different grid point layout methods. For example, a 1MM BGA provides 0.5MM grid points, and a 1.27MM BGA provides 25mil grid points, etc.; in this way, CAD engineers only need to complete the grid point setting once, and there is no need for frequent grid point setting in future designs. set up.

[0032] In a nutshell, the present invention sets different grid points for different areas, and can be divided into two situations in the process of grid point arrangement for each area: one is to use different grid points corresponding to different areas At the same time, it is arranged in the PCB design file. When the PCB designer switches and designs in different areas, there is no need to perform grid layout operations; the oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com