CD machine

A technology for optical disc drives and optical discs, which is applied to instruments, structural components of record carriers, data recording, etc., and can solve the problems of clamping discs, disc drives unable to operate, discs easily detached from trays, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] According to the above purpose, a preferred embodiment is hereby given together with drawings to illustrate the technical means used in the present invention and its effects.

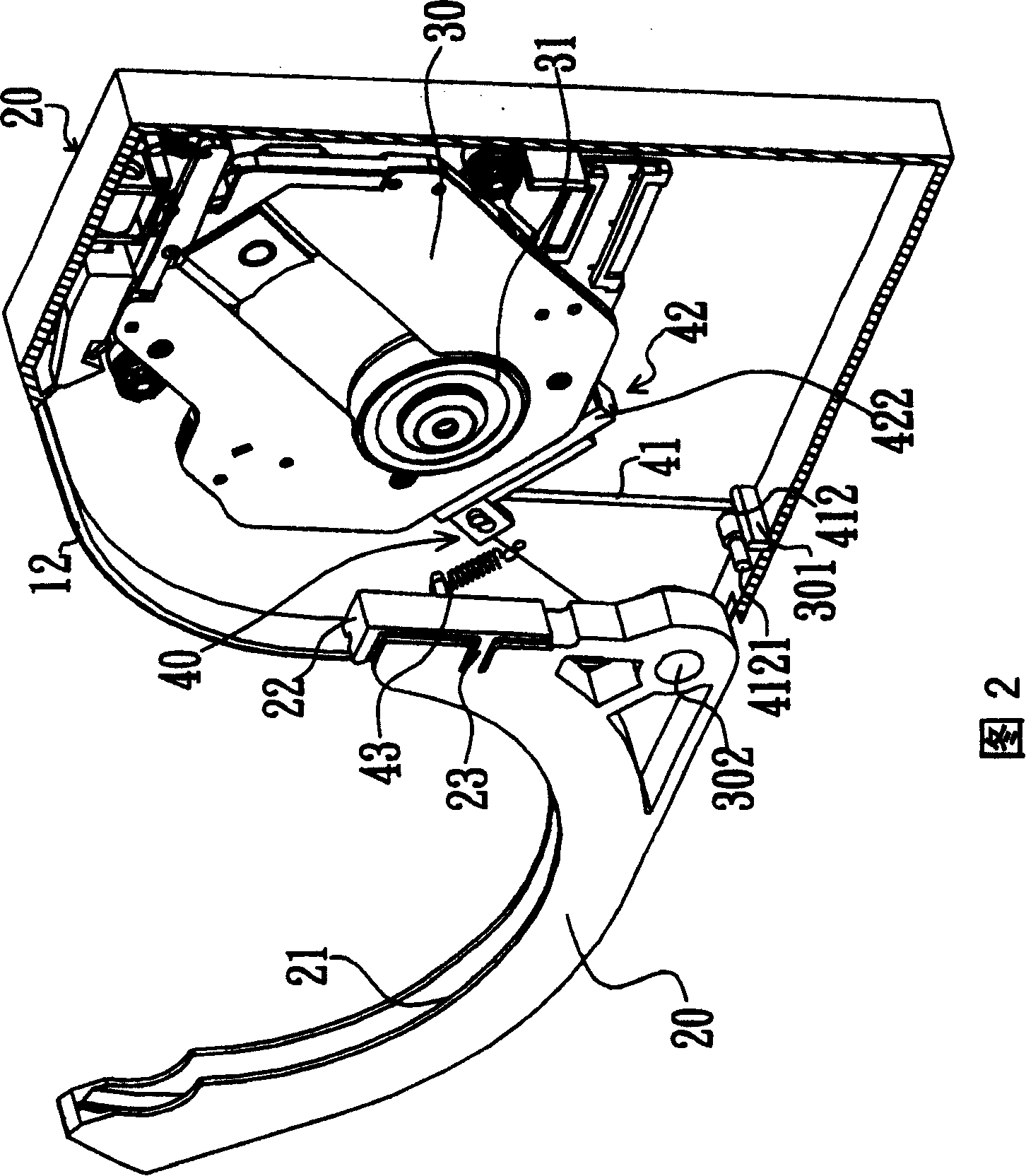

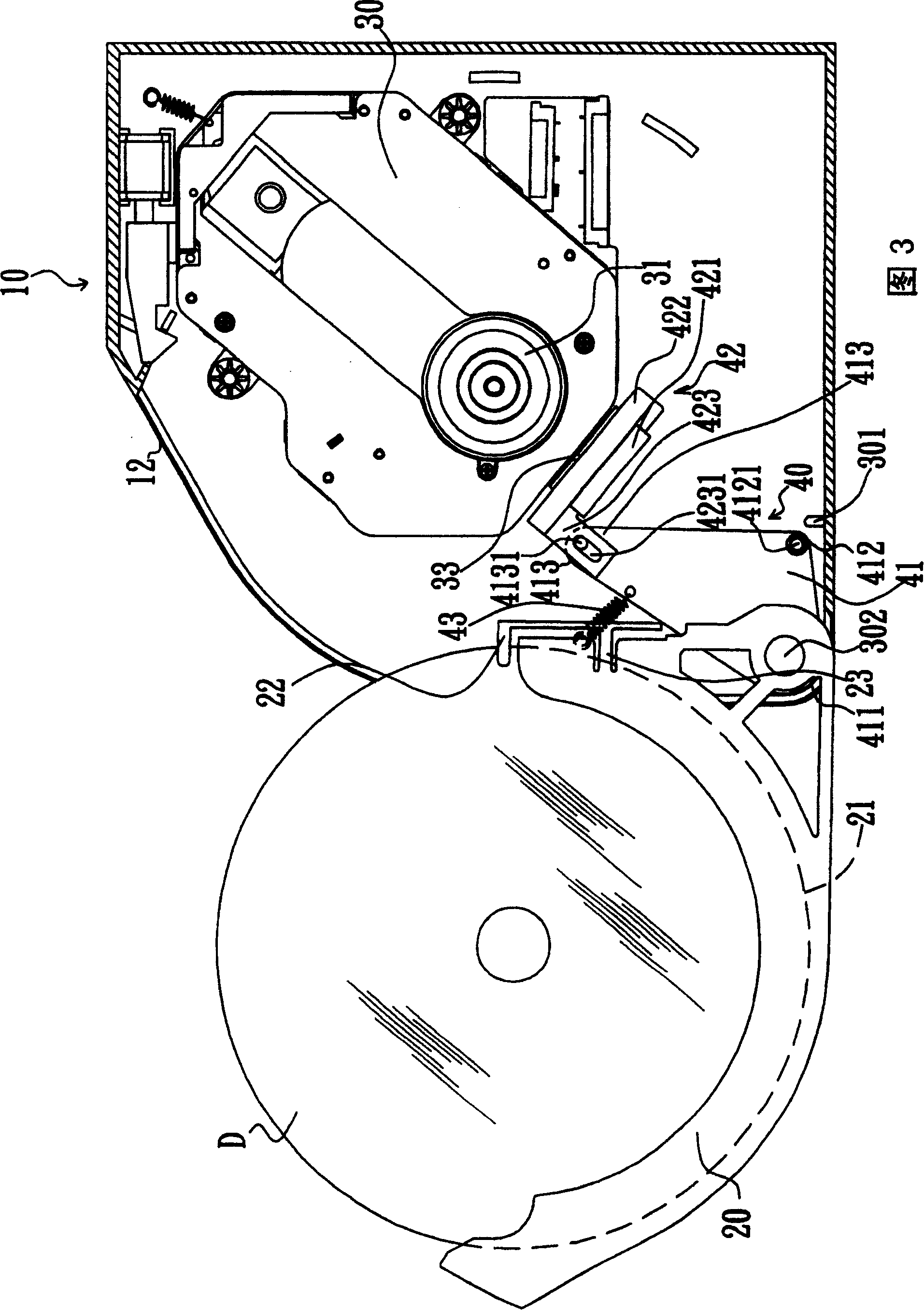

[0052] Please refer to Fig. 2, Fig. 3 and Fig. 4, Fig. 2 is a combined perspective view of the optical disc drive of the present invention, Fig. 3 is a cross-sectional view of the disc carrying device of the present invention, and Fig. 4 is a disc carrier of the present invention Cutaway view of the device loading enclosure.

[0053] As shown in the figure, the optical disc player 10 of the present invention includes a housing 11, a disc carrier 20 for carrying the optical disc D, a base 30 and a linkage mechanism 40; one side of the housing 11 has a through slot 12, wherein the optical disc carrying device 20 is pivotally connected to one side of the through groove 12, so that the optical disc carrying device 20 can be carried out and loaded into the casing 11 in a rotating manner, and the optic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com