Pulley guide loading device

A technology of loading device and pulley, which is used in the testing of measuring devices, instruments, and mechanical parts, etc., can solve the problem that the test piece cannot be loaded, and achieve the effect of simple design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

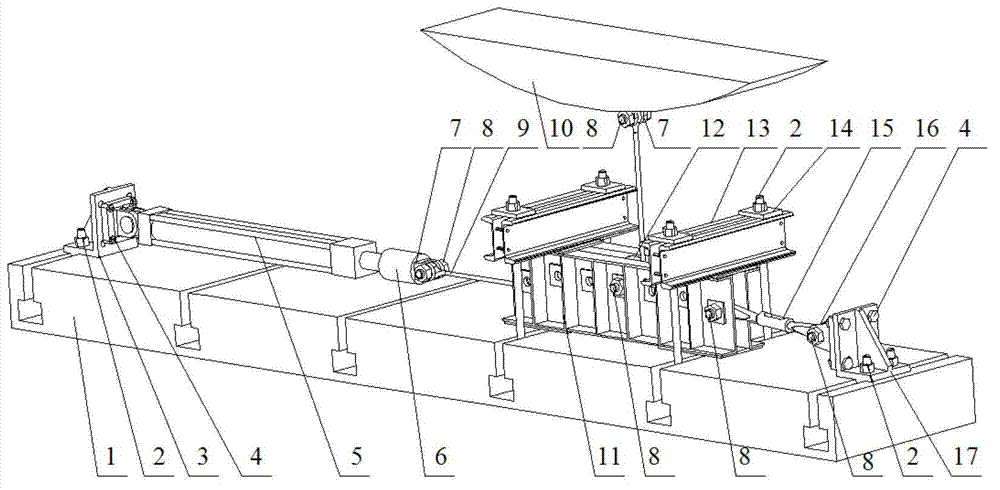

[0017] see figure 1 , the pulley guide loading device of the present invention comprises a plant floor rail 1, anchor bolts 2, a first actuator mounting seat 3, a fixing bolt 4, an actuator 5, a sensor 6, connecting ears 7, connecting bolts 8, and a steel wire rope 9 , Test piece 10, guide pulley seat 11, pulley 12, pressure beam 13, gasket 14, turnbuckle 15, fixed ears 16, second actuator mounting seat 17. Wherein, the pulley 12 is installed in the guide pulley seat 11 by connecting bolts 8, the actuator 5 is installed on the first actuator mount 3 by fixing bolts 4, one end of the steel wire rope 9 is connected to the test piece 10, and the other end is passed through the pulley. 12 After the guide, extend the guide pulley seat 11 wire rope channel to pass through, and connect to the actuator 5 through the connecting bolt 8, the connecting ears 7, and the sensor 6 successively; One end that does not pass through, the other end is also fixed on the fixed double ear 16 by con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com