Cutting roller for fragile material substrate and line drawer therewith

A technology of brittle material substrates and scribers, which is applied in the direction of manufacturing tools, glass manufacturing equipment, metal processing, etc., can solve the problems of residual stress, tool tip wear, and inability to obtain deep cutting marks, etc., and reduce the occurrence of horizontal cracks. The effect of horizontal cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

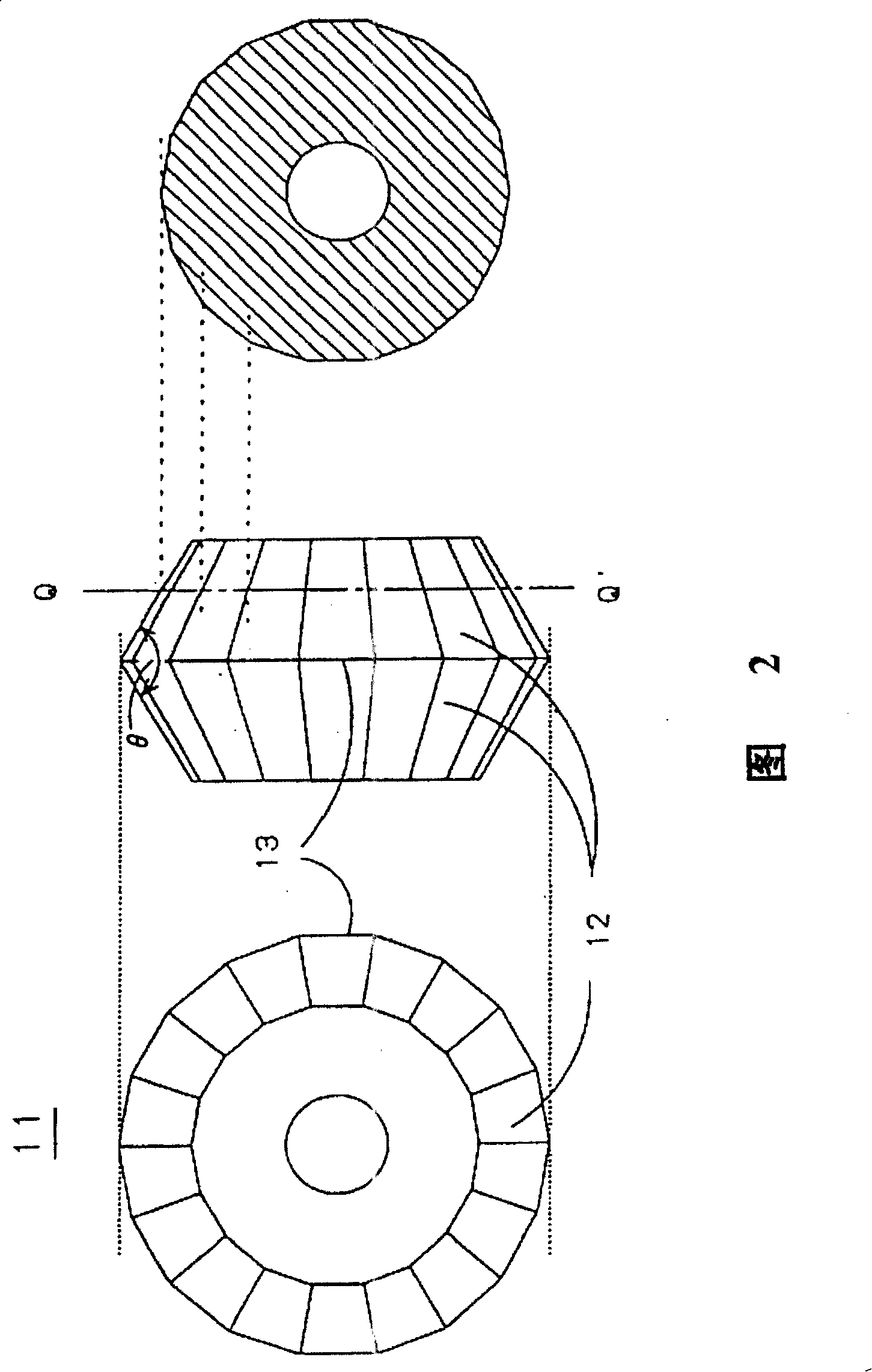

[0022] Figure 2 shows a first embodiment of the invention. The ridge line portion 13 of the V-shaped left and right blades 12 of the tip of the knife, that is, the glass cutting cutter wheel 11, is formed into a regular 60-angle shape (results viewed from the side; simplified to a regular 18-angle shape in the figure for easy understanding), and by including all Cut off the blade face on the plane of each side of the regular 60-angle, and form the described V-shaped blade 12 with a knife edge angle 0 of 125°. That is to say, at any place on the blade 12 containing the blade tip 13, the side section at this place becomes a regular 60-angle, and the side section on the line Q-Q' in Fig. 2 is shown in the right figure.

[0023] In addition, as can be understood from the production examples described later, the blade tip 13 is actually continuously formed by continuously forming the blade 12 .

[0024] The table below represents the dimensions of the glass cutter wheel 11 of this...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com